Self-propelled miniature rotary cultivator

A self-propelled, rotary tiller technology, applied in the fields of farming equipment, agricultural machinery and equipment, and applications, can solve the problems of poor turning maneuverability and aggravate the loss of parts, and achieve convenient hydraulic control, improved work efficiency, and stable power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0025] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

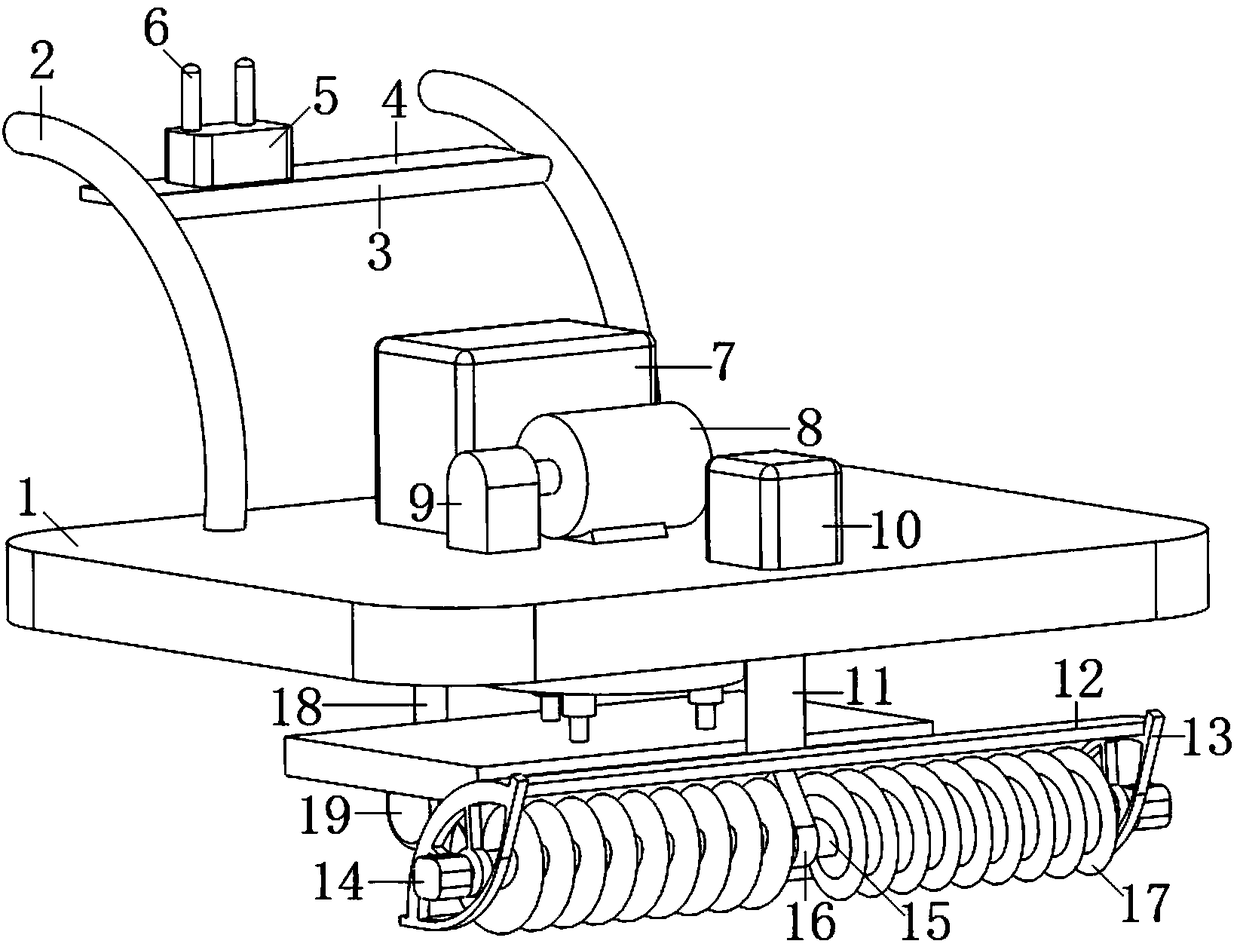

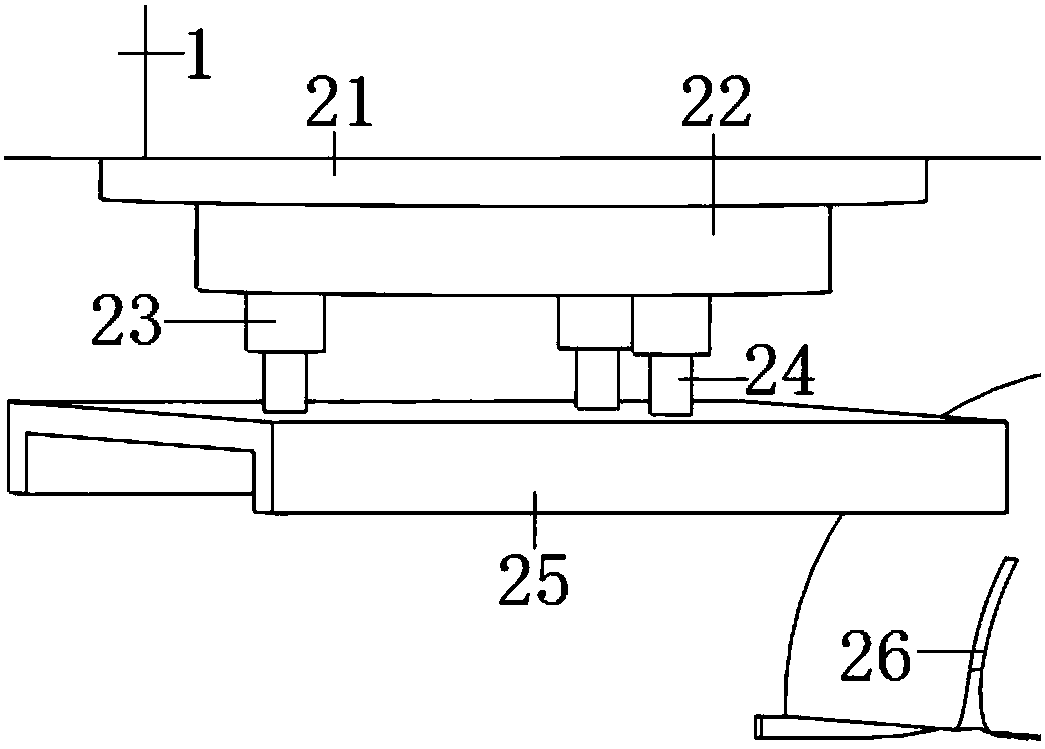

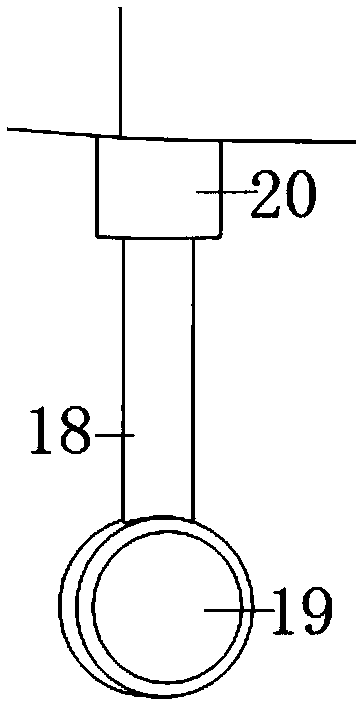

[0026] Such as Figure 1-5 As shown, the present invention provides a kind of self-propelled small-sized rotary tiller, comprising:

[0027] The hydraulic power device is provided with a main board 1 in the middle of the whole device, and the main board 1 is a rectangular metal plate. Two handles 2 are provided on the rear side of the upper surface of the main board 1, and a connecting rod 3 is provided in the middle of the two handles 2. The rear side of the connecting rod 3 is provided with a support plate 4, the upper side of the support plate 4 is provided with a hydraulic val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com