Motorized spindle reliability test bed based on twin trawling loading

A technology of drag loading and electric spindle, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of low test efficiency, poor reliability, and high test cost, and improve reliability and save electric energy. , the effect of reducing the number of additional equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

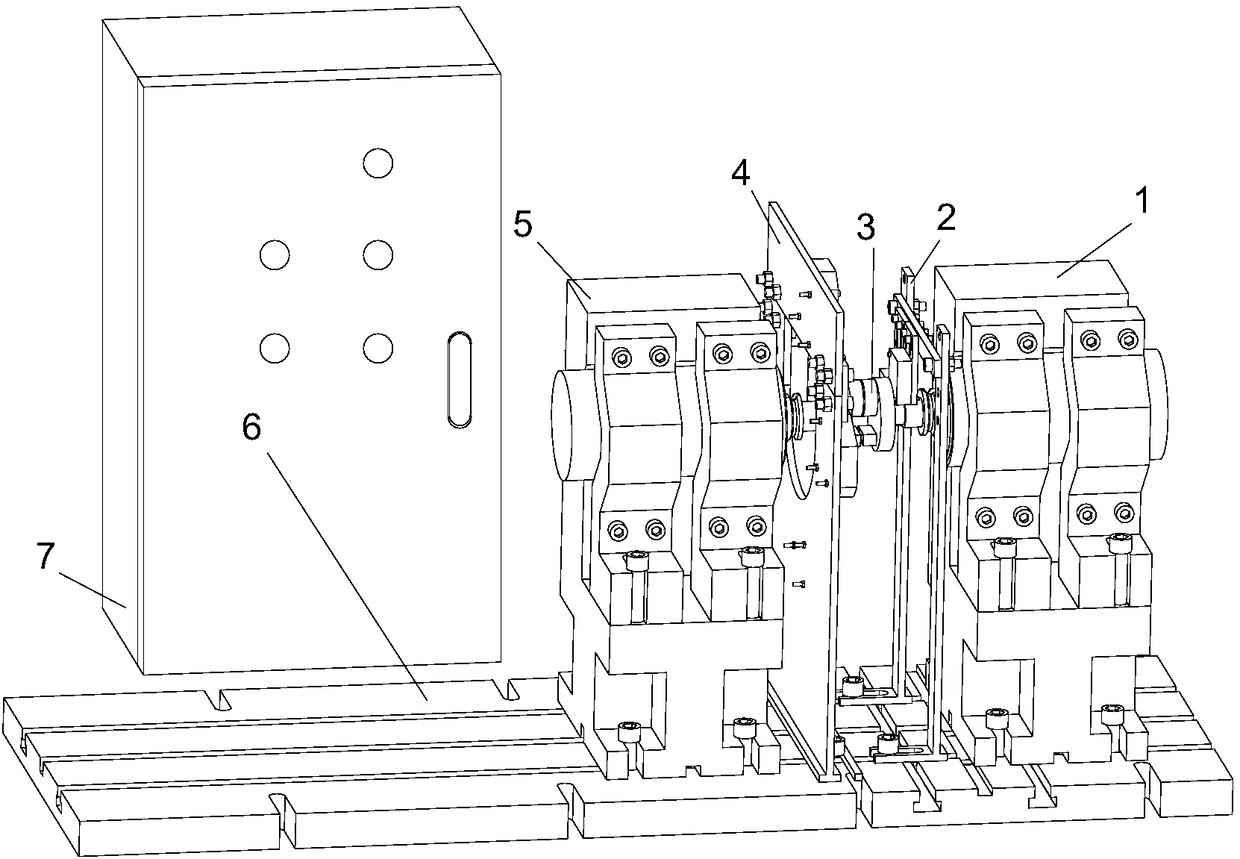

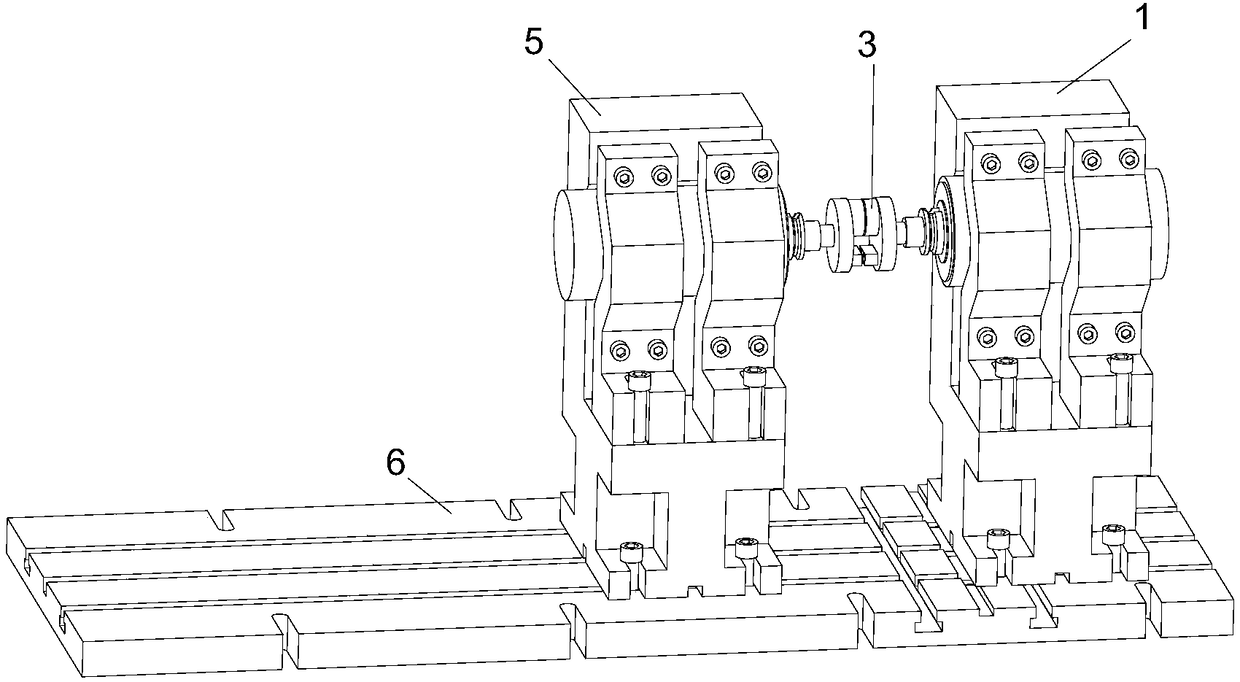

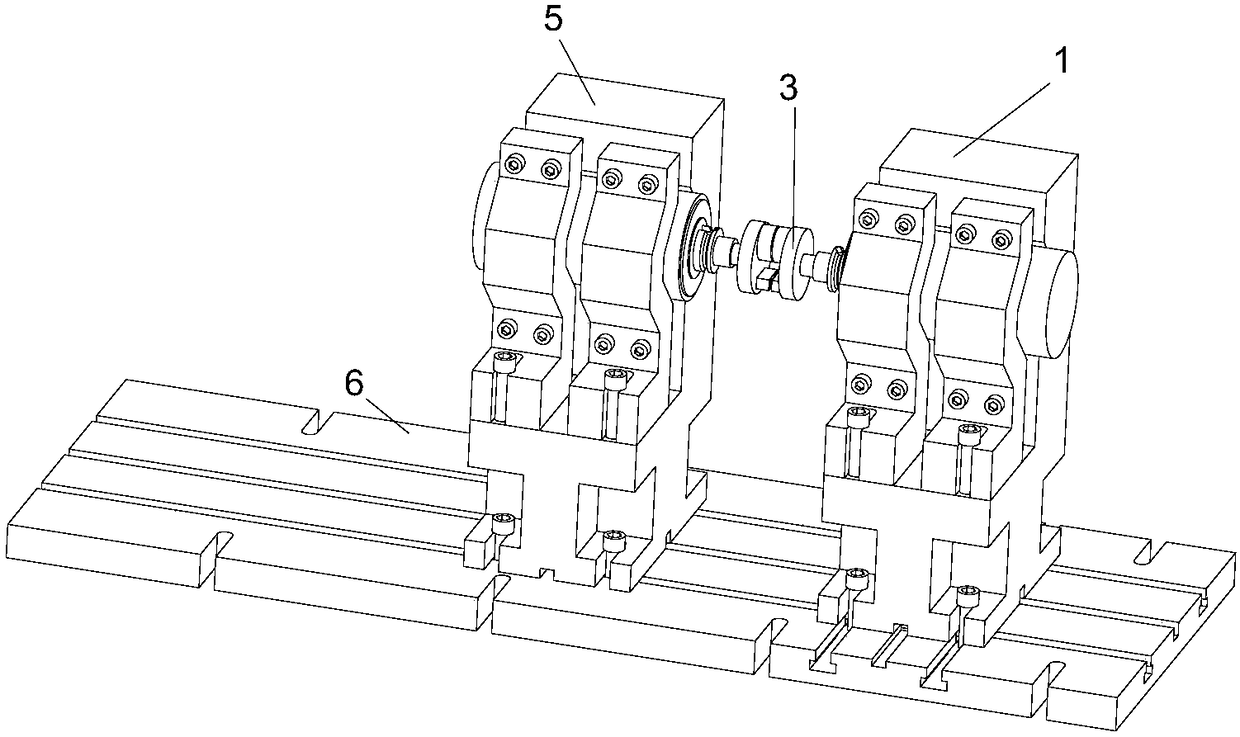

[0039] see figure 1 — image 3 , an electric spindle reliability test bench based on drag loading, the test bench includes an electric spindle A installation part 1, a point laser displacement sensor installation part 2, a mechanical loading part 3, a line laser displacement sensor installation part 4, and an electric spindle B Mounting part 5, level rail 6 and control part 7.

[0040] The installation part 1 of the electric spindle A and the installation part 5 of the electric spindle B are fixed on the horizon iron 6; the installation part 2 of the point laser displacement sensor and the installation part 4 of the line laser displacement sensor are arranged on the installation part 1 and 4 of the electric spindle A. Between the installation parts 5 of the electric spindle B, and fixed on the horizon iron 6; the mechanical loading part 3 is arranged between the installation part 2 of the point laser displacement sensor and the installation part 4 of the line laser displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com