Mechanical part maintenance process

A technology of mechanical parts and technology, which is applied in the field of mechanical parts maintenance technology, can solve the problems of long time spent on bearings, low processing efficiency, cumbersome procedures, etc., and achieve the goal of simplifying the oiling procedure, reducing the oiling time, and improving the oil injection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

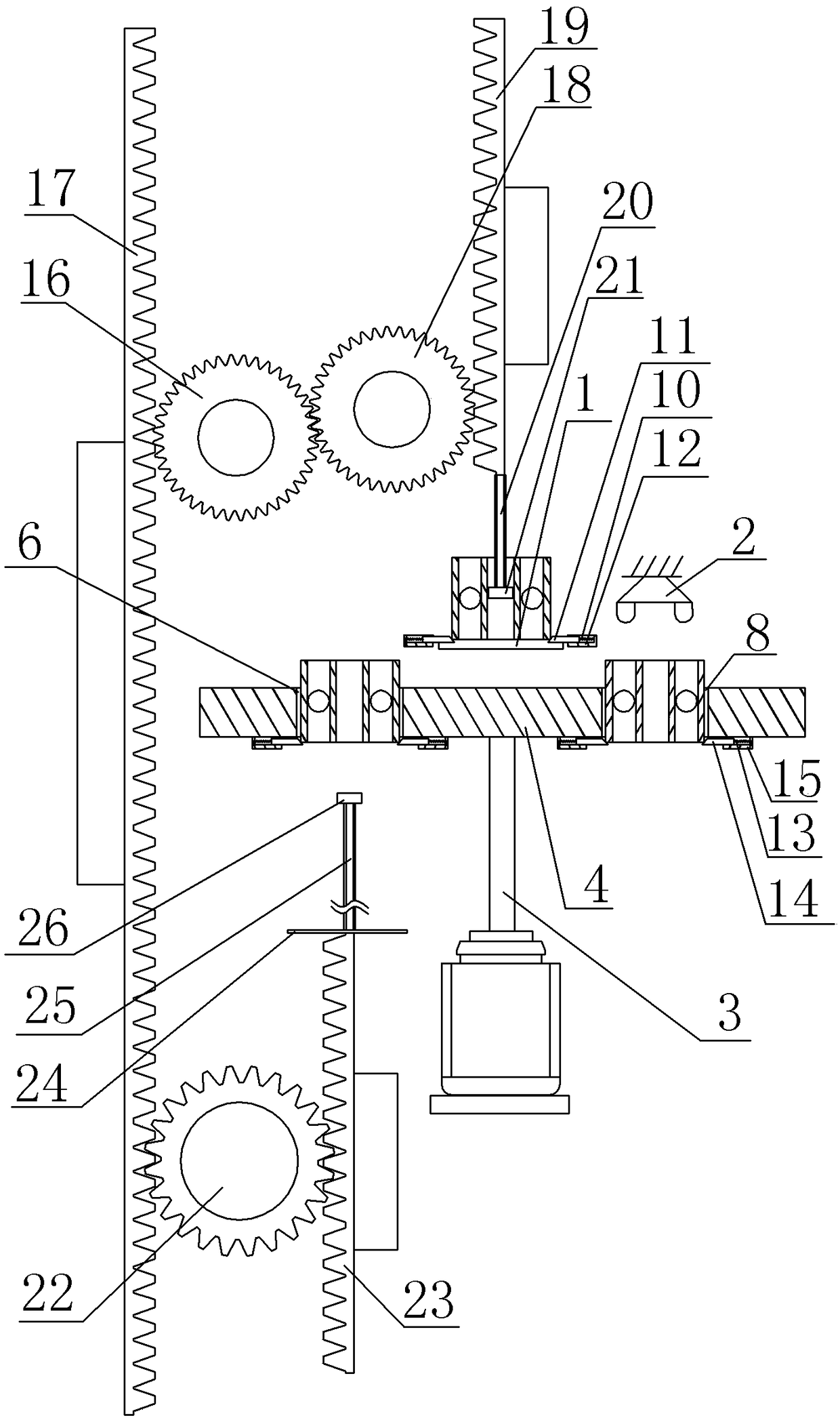

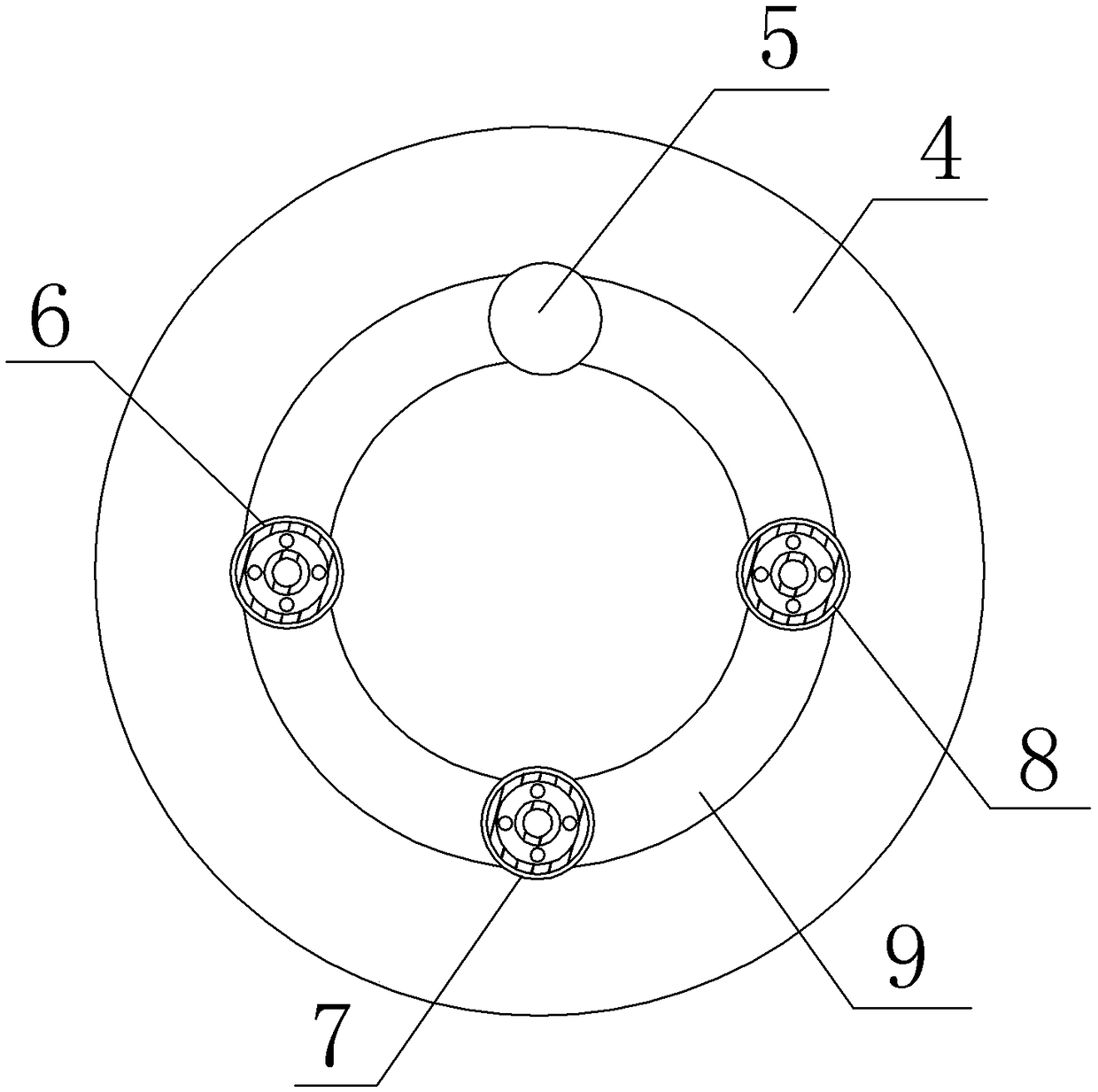

[0019] The reference signs in the drawings of the description include: conveyor belt 1, fuel injection nozzle 2, rotating rod 3, rotating disk 4, No. 1 vertical hole 5, No. 2 vertical hole 6, No. 3 vertical hole 7, No. 4 vertical hole 8, Recovery groove 9, first spring 10, first wedge block 11, first slide block 12, second spring 13, second wedge block 14, second slide block 15, first gear 16, first rack 17, the first Two gears 18, the second tooth bar 19, put piece pipe 20, put piece airbag 21, the 3rd gear 22, the 3rd tooth bar 23, support plate 24, take piece pipe 25, take piece airbag 26.

[0020] The maintenance process of mechanical parts specifically includes the following steps:

[0021] Step 1: Prepare a figure 1 The fuel injection equipment for mechanical parts shown includes a conveyor belt 1, a fuel injection nozzle 2, a rotating mechanism, a pick-and-place mechanism, a first suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com