Tunnel cavity-free lining trolley capable of performing mobile shooting

A technology for lining trolleys and voids, which is used in tunnel lining, tunnel, shaft lining and other directions, and can solve the problem of inability to effectively observe the pouring situation at the far end of the formwork.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

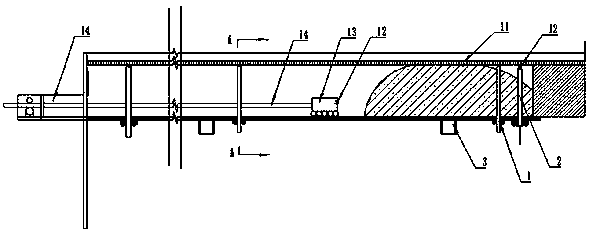

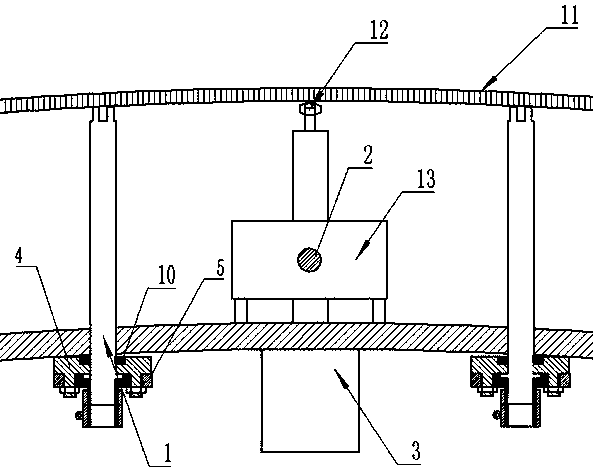

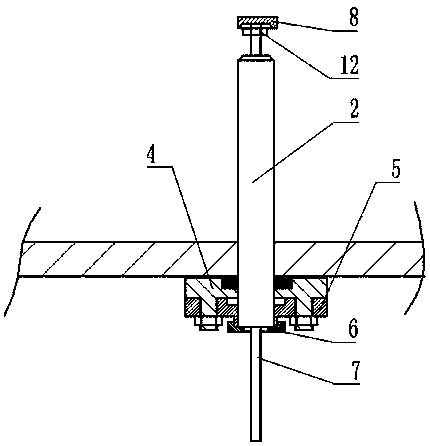

[0031] Such as figure 1 , the observation car 13 is set on the vault template, the observation probe 12 is installed on the observation car 13, the guide rod 14 is installed at the left end of the observation car 13, and the guide rod 14 is connected to the placement room 15 provided at the end mold place, and the guide rod 14 can be controlled by the winch mechanism. Rod 15 advances or retreats, and can control dolly to retreat in the placement room 15 from the perfusion hole 3 at the farthest end, and placement room 15 is provided with valve, closes valve after dolly returns to placement room 15. The wheelbase of both sides rollers on the observation car 13 is greater than the diameter of the pouring hole 3 .

[0032] Drill holes in the top form of the lining trolley, and drill an observation hole at the highest longitudinal point of the vault formwork. The observation hole is located at the end closest to the lining of the upper ring, and drill 2-5 groups of grouting holes ...

Embodiment 2

[0037] As shown in the figure, an observation car 13 is set on the vault formwork, an observation probe 12 is installed on the observation car 13, a guide rod 14 is installed on the left end of the observation car 13, and the guide rod 14 is connected to the placement room 15 provided at the end mold, and can be moved by the winch mechanism. Control the guide rod 15 to advance or retreat, and the dolly can be controlled to retreat from the farthest filling hole 3 to the placement room 15. The placement room 15 is provided with a valve, and the valve is closed after the dolly returns to the placement room 15.

[0038] Drill holes in the top form of the lining trolley, and drill an observation hole at the highest longitudinal point of the vault formwork. The observation hole is located at the end closest to the lining of the upper ring, and drill 2-5 groups of grouting holes according to the number of pouring holes 3. There are two grouting holes for each group, which are symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com