Vertical rotating and lifting construction method of steel structure arch rib

A construction method and technology for steel structures, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of large total weight of arch bridges, high synchronization requirements, low construction safety, etc., and achieve high installation quality and reduce lifting difficulty. , the effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

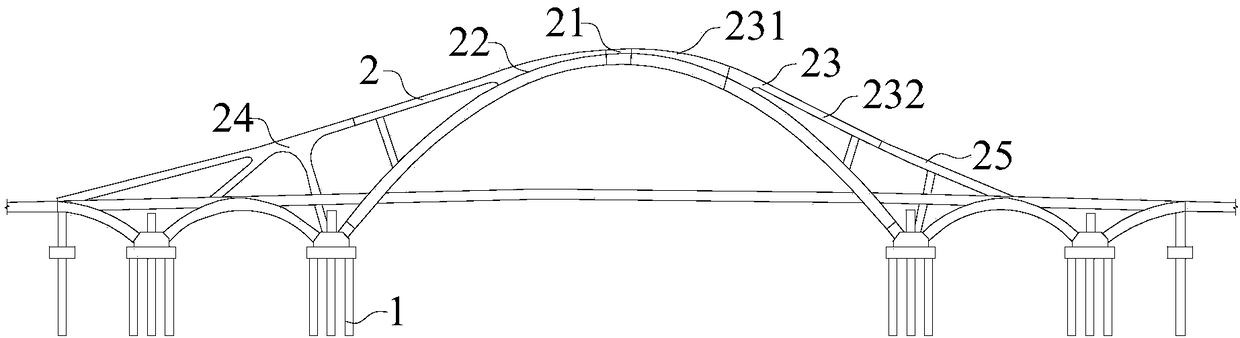

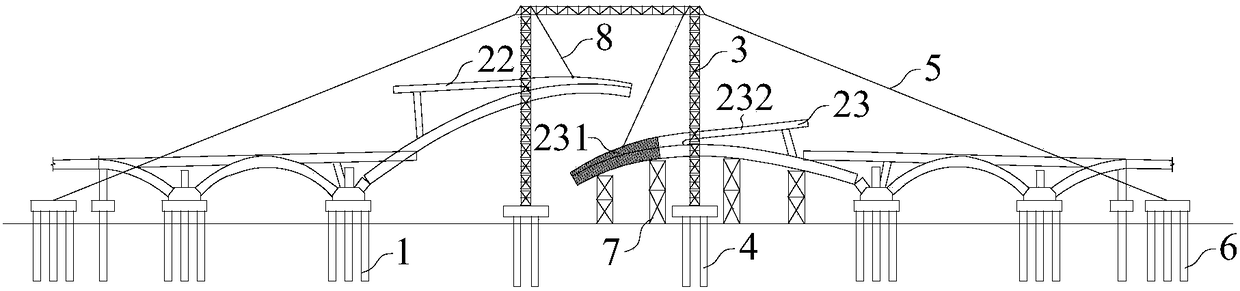

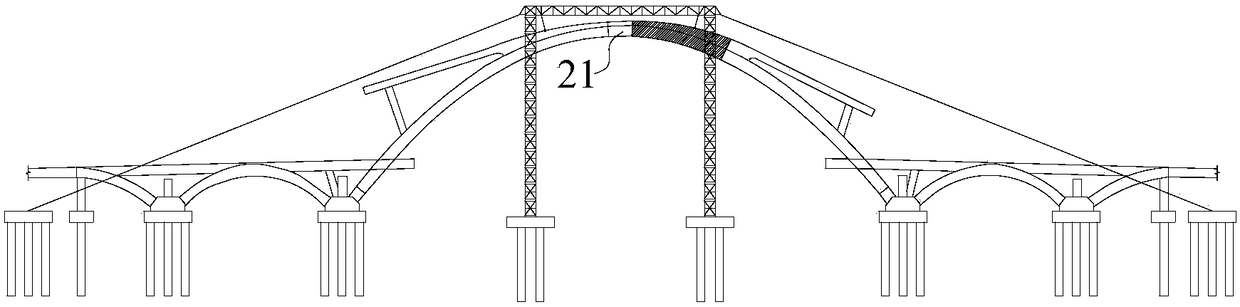

[0024] Such as Figure 1-4 As shown, a kind of steel structure arch rib vertical rotation lifting construction method of the present invention comprises:

[0025] S1. Complete the construction of the concrete pier 1 at both ends of the arch bridge 2, the temporary foundation of the main arch 7, the temporary foundation of the tower 4 and the temporary anchor point foundation 6 of the wind-covering system, and set the arch foot pre-set on the two arch foot piers 1 of the main arch. buried section, and install a temporary hinge on the pre-buried section of the arch foot;

[0026] The erection and installation of the tower 3 is completed on the temporary foundation 4 of the tower, and the wind system 5 is set up between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com