Oilfield oil sludge cleaning agent and preparation method thereof

A technology for sludge and cleaning agent, applied in detergent compounding agent, detergent composition, chemical instrument and method, etc., can solve the problems of incomplete cleaning and low oil cleaning rate, and achieve complete oil cleaning without polluting the environment. , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

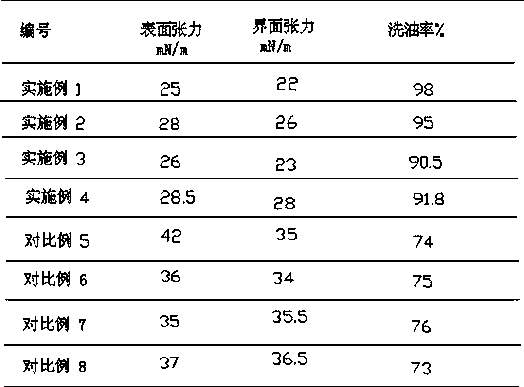

Examples

Embodiment 1

[0017] Take a 250ml glass reaction vessel and add 80g of water, 2g of sorbitan fatty acid ester (Span 80), 10g of sodium dodecylbenzenesulfonate, and dodecyltrimethylammonium chloride (1231) in sequence 1.6g, coconut oil diethanolamide (6501) 4g, sodium tripolyphosphate 1.2g, sodium citrate 1.2g, stir for 30min until completely dissolved, stirring speed 60 rpm, to make oilfield sludge cleaning agent.

Embodiment 2

[0019] Take a 250ml glass reaction vessel and add 84g of water, 2g of sorbitan fatty acid ester (Span 80), 8g of sodium dodecylbenzenesulfonate, and 1.6g of dodecyltrimethylammonium chloride (1231) , Coconut oil diethanolamide (6501) was 2g, sodium tripolyphosphate 1.2g, sodium citrate 1.2g, stirred for 20min until completely dissolved, and the stirring speed was 90 rpm to prepare oilfield sludge cleaning agent.

Embodiment 3

[0021] Take a 250ml glass reaction vessel and add 84.g of water, sorbitan fatty acid ester (Span 80) to 2g, sodium dodecylbenzenesulfonate 6g, dodecyltrimethylammonium chloride (1231) to 1.6g, coconut oil diethanolamide (6501) 4g, sodium tripolyphosphate 1.2g, sodium citrate 1.2g, stir for 30min until completely dissolved, stirring speed 60rpm, make oilfield sludge cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com