Phenolic resin adhesive cloth gluing method used for manufacturing bearing retainer

A bearing cage and phenolic resin glue technology, which is applied to bearing components, shafts and bearings, material inspection products, etc., can solve the problems of changing the quality of the adhesive tape, not easy to find, and difficult to control the gluing process of the phenolic resin adhesive tape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0046] Embodiment 1: A method for gluing a phenolic resin adhesive tape for manufacturing a bearing cage described in this embodiment is carried out according to the following steps:

[0047] 1. Prepare glue:

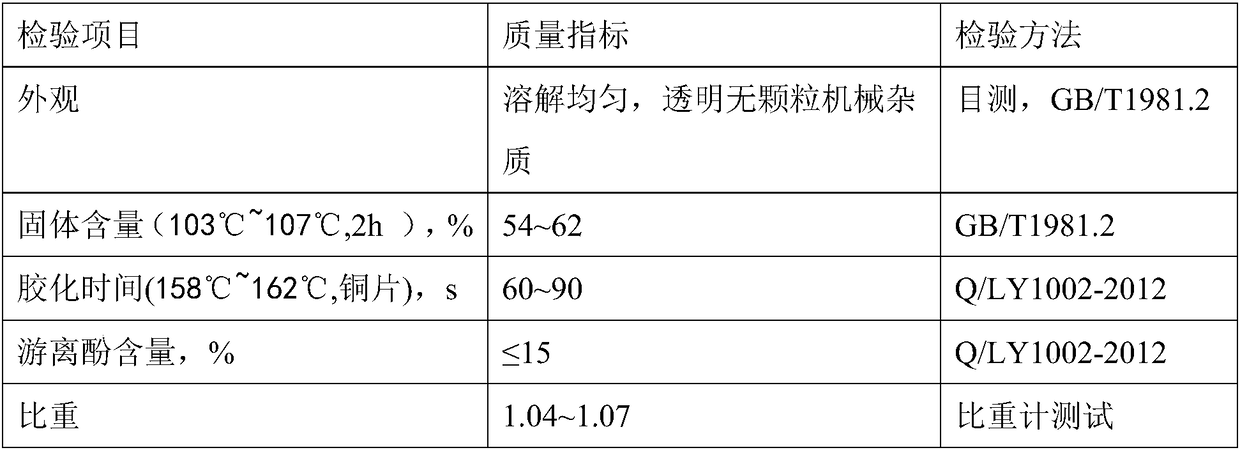

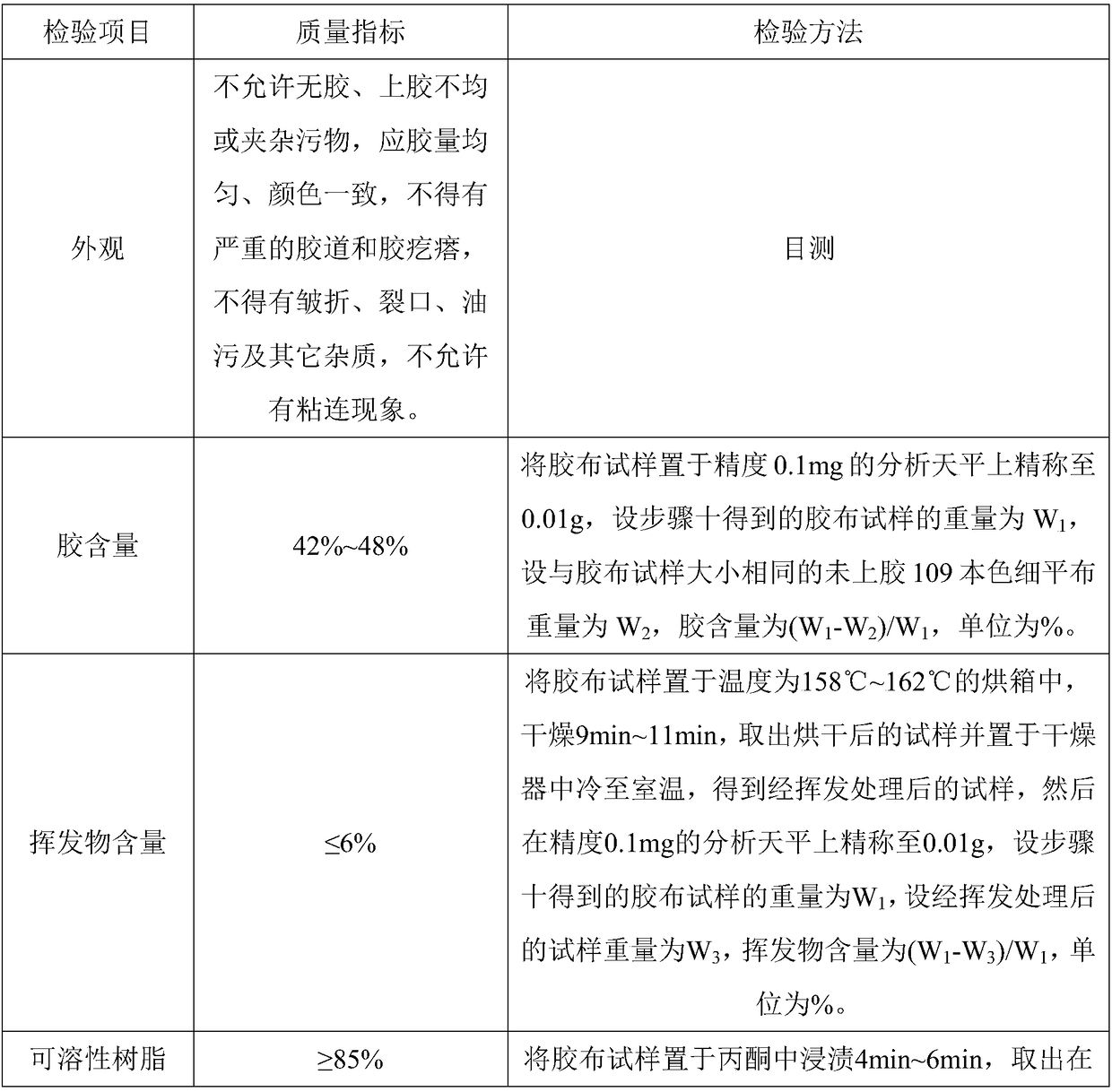

[0048] Pour the phenolic resin glue into the glue tank; after the phenolic resin glue is cured at a temperature of 103°C to 107°C for 1.5h to 2.5h, the solid content is 54% to 62%. Under the condition of 158°C-162°C, the gelling time of bonding copper sheets to copper sheets is 60s-90s, the free phenol content of the phenolic resin glue is ≤15%, and the specific gravity of the phenolic resin glue is 1.04-1.07;

[0049] Second, cloth preparation:

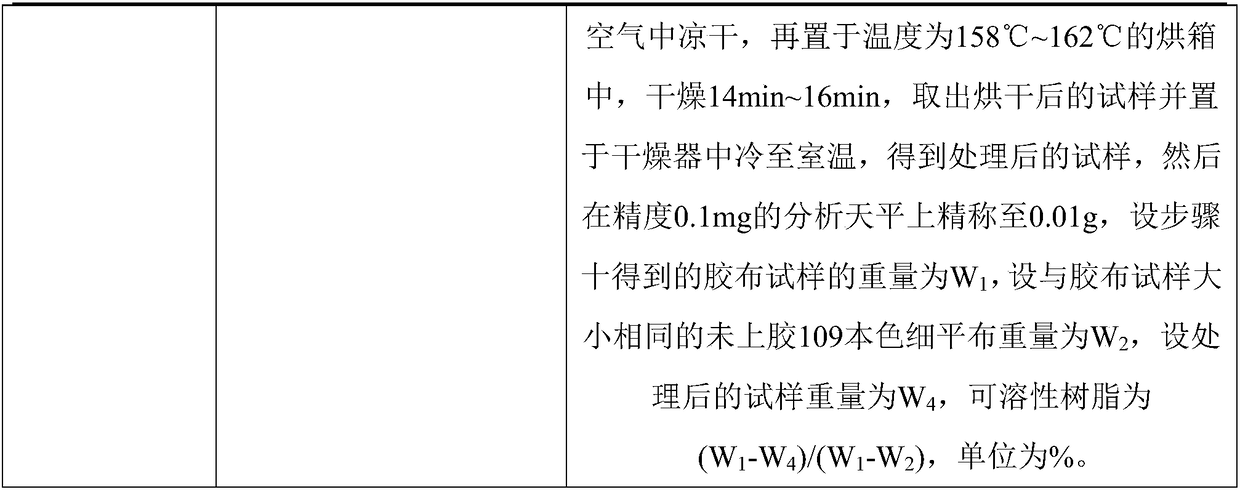

[0050] 109 Natural muslin cloth prepared for use in the rubber category;

[0051] 3. Turn on the dryer:

[0052] Turn on the dryer, and set the drying temperature of the three stages at 127°C to 133°C;

[0053] 4. Turn on and adjust the glue machine:

[0054] Turn on and adjust the gluing machine, the gap between the nip ...

specific Embodiment approach 2

[0095] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 3, the dryer is turned on, and the drying temperature of the three stages is set at 130°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0096] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: open and adjust the gluing machine in step four, the gap between the nip rollers is 0.19mm, adjust the rotation speed of the rollers so that the pointer of the ammeter is at 65A, And make the transmission speed of the transmission cloth 1.7m / min. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com