Material distributing method for simulation ceramic tiles with internal grains and ceramic tiles

A texture and ceramic tile technology, applied in the distribution method of simulated ceramic tiles and the ceramic tile field, can solve the problems of poor controllability of material mixing, texture position and size, and achieve the effect of simplifying equipment structure, improving cloth efficiency and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

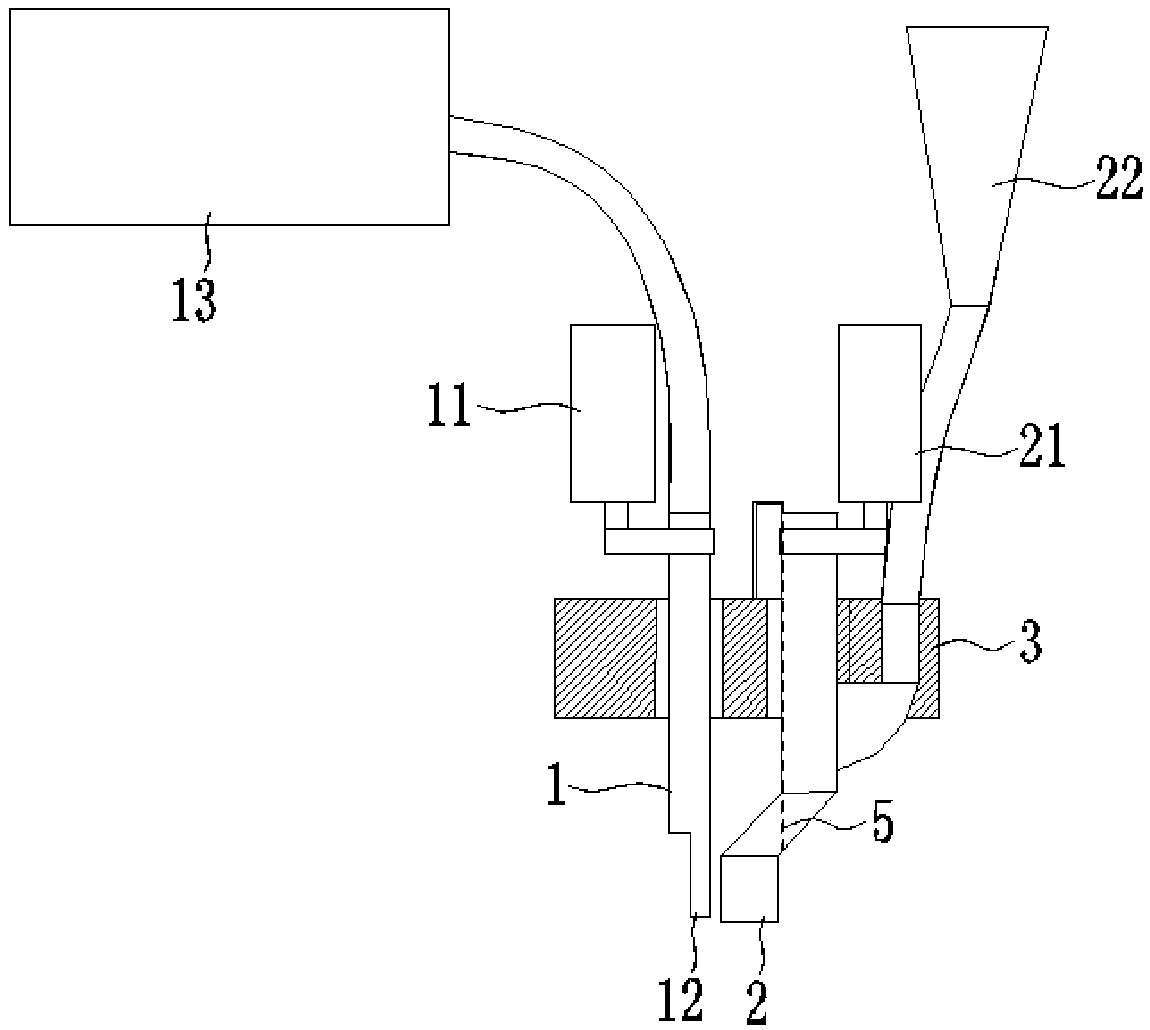

[0069] A method for distributing simulated ceramic tiles with internal textures, comprising steps (1) to (4), specifically as follows.

[0070] (1) Spread the basic powder on the conveyor belt to obtain the billet.

[0071] (2) Part of the powder of the blank is removed, and the place where the powder is removed is filled with toner, so that the adobe of the ceramic tile forms a bottom texture.

[0072] Part of the powder of the billet is removed by means of negative pressure suction of the suction pipe. The colored powders filled in the powder removal part are powders of at least two colors. The discharge pipe is used to fill the place where the powder is removed with toner, the discharge pipe is adjacent to the suction pipe, and the material is discharged in the space formed by the suction at the same time.

[0073] The plurality of suction pipes and the plurality of discharge pipes cooperate with each other, and the plurality of discharge pipes release at least two colors...

Embodiment 2

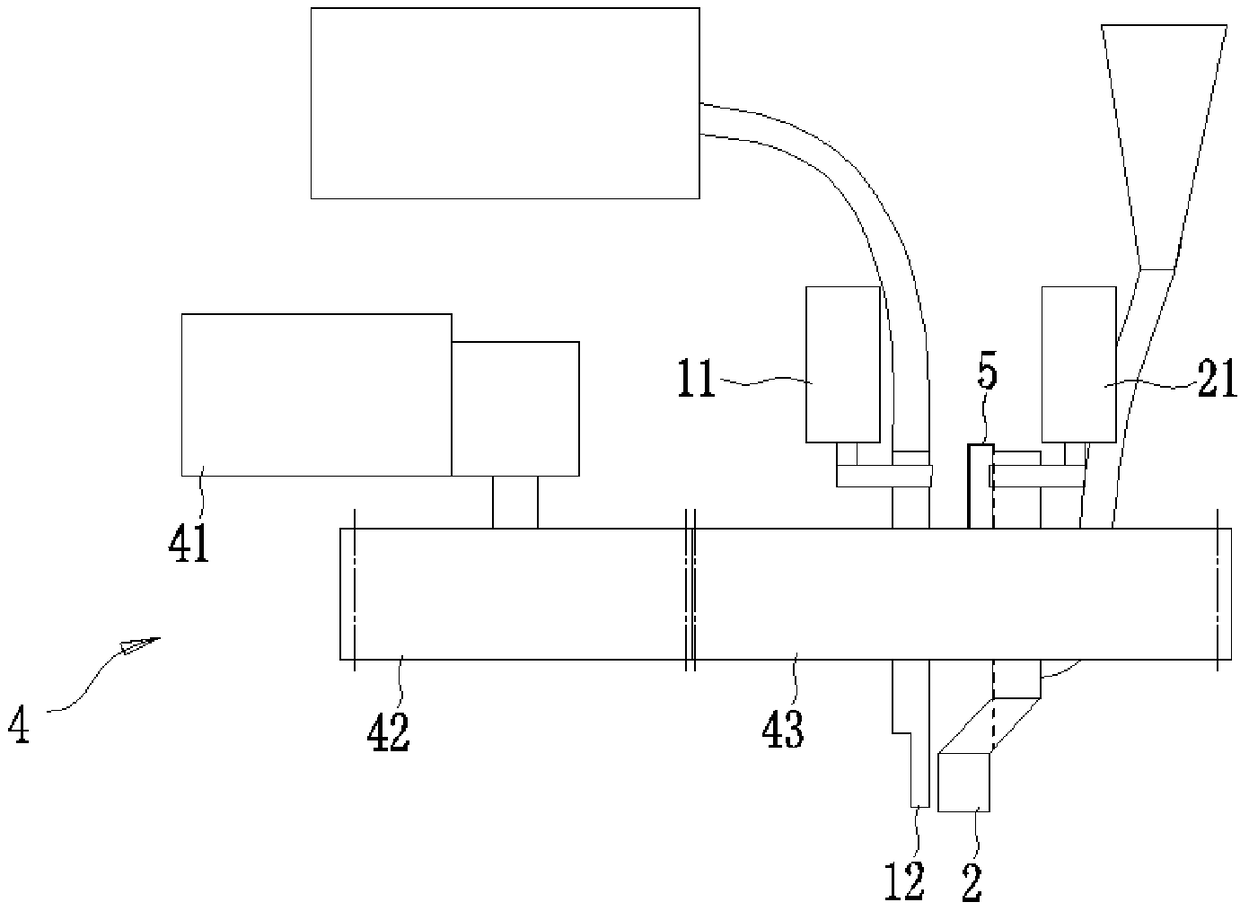

[0084] A method for distributing simulated ceramic tiles with internal textures, comprising steps (1) to (5), specifically as follows.

[0085] (1) Spread the basic powder on the conveyor belt to obtain the billet.

[0086] (2) Part of the powder of the blank is removed, and the place where the powder is removed is filled with toner, so that the adobe of the ceramic tile forms a bottom texture.

[0087] Part of the powder of the billet is removed by means of negative pressure suction of the suction pipe. The colored powders filled in the powder removal part are powders of at least two colors. The discharge pipe is used to fill the place where the powder is removed with toner, the discharge pipe is adjacent to the suction pipe, and the material is discharged in the space formed by the suction at the same time.

[0088] The plurality of suction pipes and the plurality of discharge pipes cooperate with each other, and the plurality of discharge pipes release at least two colors...

Embodiment 3

[0101] A method for distributing simulated ceramic tiles with internal textures, comprising steps (1) to (5), specifically as follows.

[0102] (1) Spread the basic powder on the conveyor belt to obtain the billet.

[0103] (2) Part of the powder of the blank is removed, and the place where the powder is removed is filled with toner, so that the adobe of the ceramic tile forms a bottom texture.

[0104] Part of the powder of the billet is removed by means of negative pressure suction of the suction pipe. The colored powders filled in the powder removal part are powders of at least two colors. The discharge pipe is used to fill the place where the powder is removed with toner, the discharge pipe is adjacent to the suction pipe, and the material is discharged in the space formed by the suction at the same time.

[0105] The plurality of suction pipes and the plurality of discharge pipes cooperate with each other, and the plurality of discharge pipes release at least two colors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com