Curve design of rolling mill work roller for high-temperature large-rolling-reduction technology of large square billet and rectangular billet

A technology of high temperature and high pressure and curve design, which is applied in the direction of rolls, metal processing equipment, metal rolling, etc., can solve the problems such as difficult to eliminate loose shrinkage defects, achieve improvement of loose shrinkage defects, wide adjustable range, and promote The effect of shrinkage cavity width compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

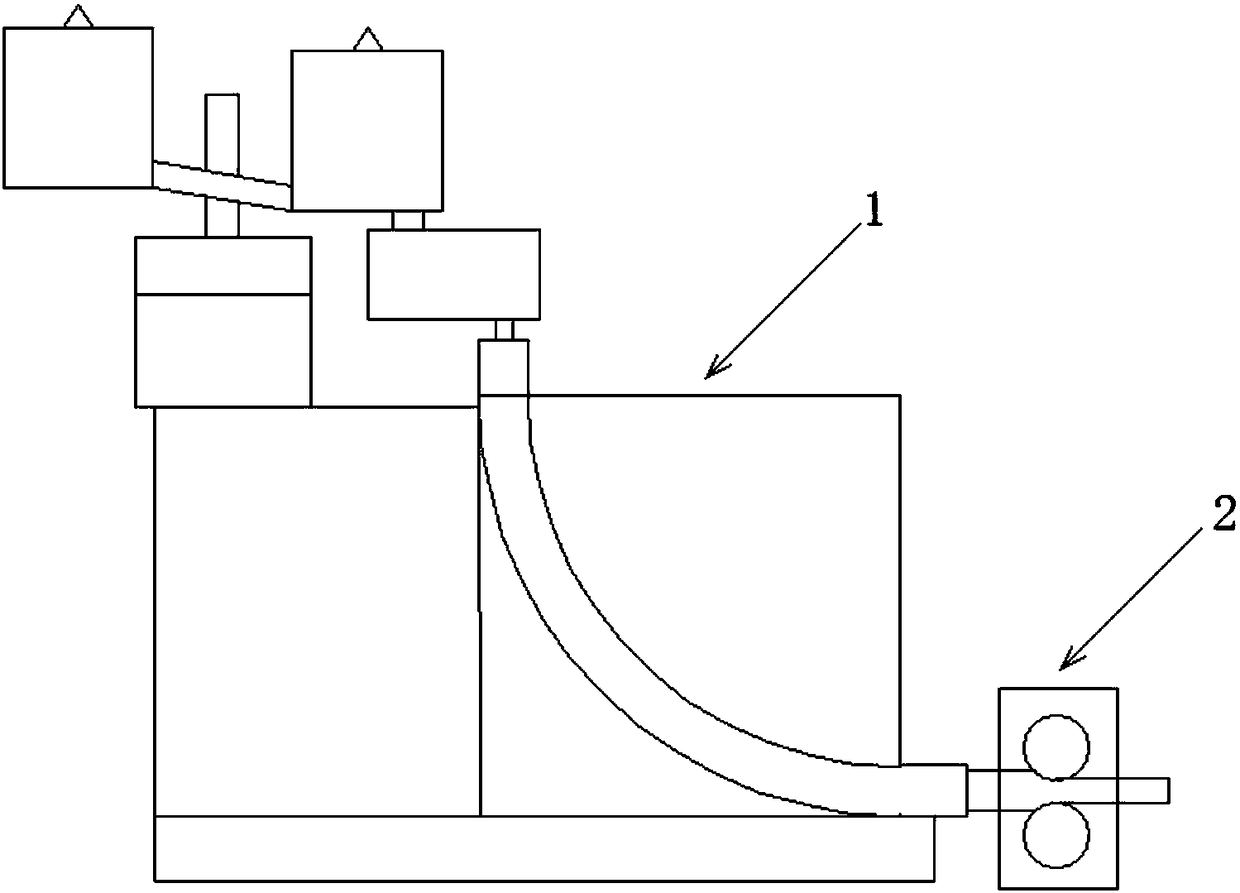

Embodiment 1

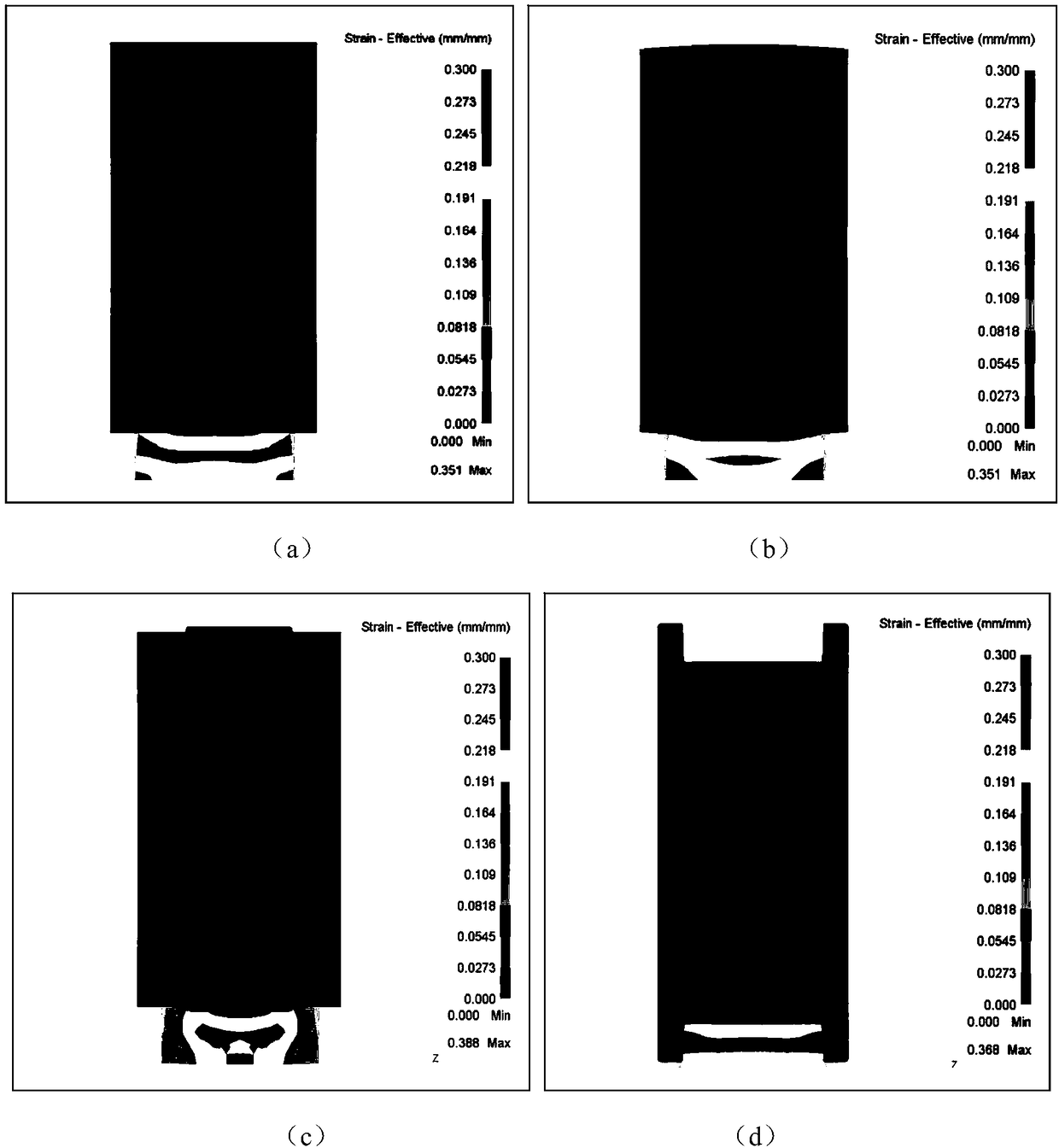

[0041] The 300mm×360mm rectangular continuous casting slab of 16Mn steel produced by actual continuous casting is cast at a casting speed of 0.6m / min. First, evaluate the central shrinkage cavity level of the continuous casting slab produced stably; according to the idea of single-pass high temperature and high pressure, set up flat rolls, flanged rolls, parabolic convex rolls, box-shaped pass rolls and the compound at the end of continuous casting. The roller completes the rolling deformation process, and the shrinkage cavity of the deformed billet is counted and rated. Compare the above evaluation results to verify the effect of roll shape on shrinkage cavity improvement.

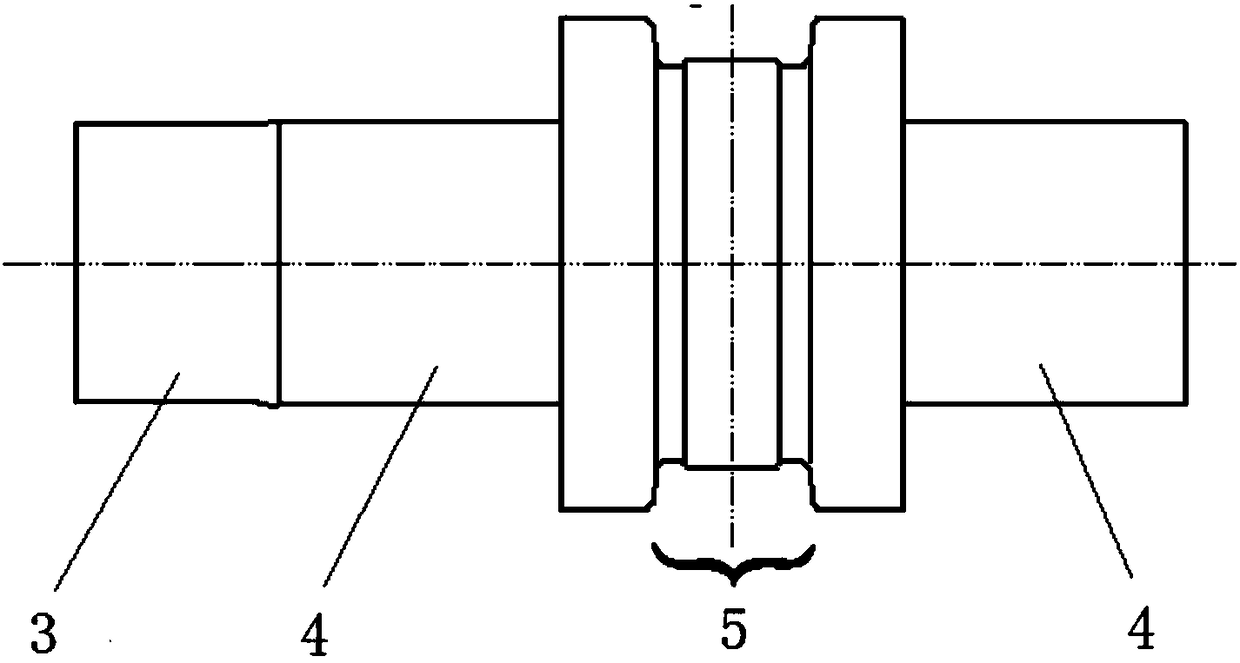

[0042] The continuous casting slab completed the rolling deformation process under high temperature and high pressure under the same temperature field. At this time, the surface temperature of the slab was 952°C, and the core temperature was 1370°C. Work roll parameters: the flange width coefficient of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com