Laser-type walnut shell-slitting machine

A laser type, walnut technology, applied in the direction of shelling, pod removal, food science, etc., to achieve the effect of good scratching quality, improved shell breaking rate, and high dew kernel rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

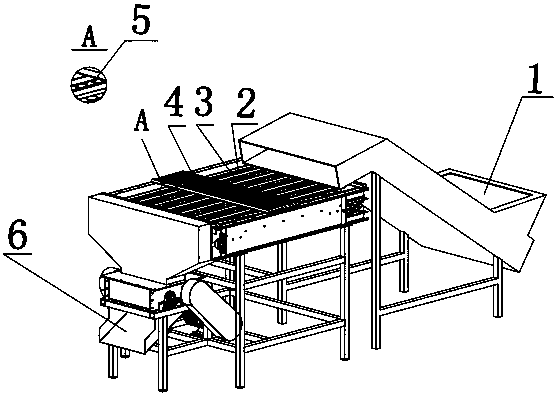

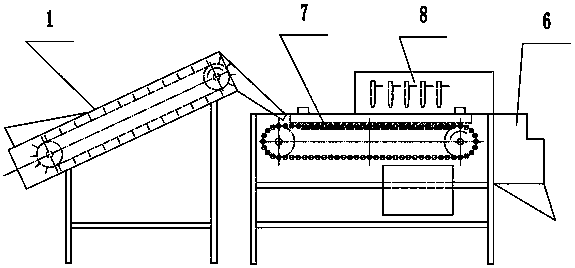

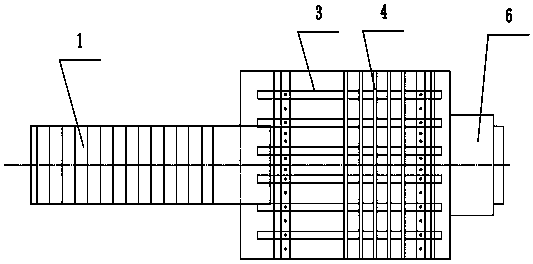

[0014] Embodiment 1: refer to figure 1 , figure 2 , image 3 , the invention relates to a laser type walnut scoring machine, comprising a feeding device (1), a roller sorting device (7), a laser scoring device (8) and a discharging device (6); it is characterized in that walnuts are made of walnut The hoist is transported to the stainless steel roller conveyor belt, on which there are evenly spaced track baffles (3) to assist in sorting, so that the walnuts can move along the determined track and roll in the above track to the laser processing station in an orderly manner. There are a pair of staggered laser probes (5) on each track. When the walnut passes the first laser probe, it is cut once, and when it continues to move with the roller (2), it passes the second laser probe. At this time, the walnut is cut again, thereby effectively ensuring that the walnut shell is effectively scratched and the quality of the scratch is guaranteed. The roller sorting device includes a ...

Embodiment 2

[0015] Embodiment 2: Compared with Embodiment 1, the difference of this embodiment is that the powers of the two rows of laser probes on the suspension beams are different, and the power of the laser probes of the first row of suspension beams is 130W. The laser probe power of the second row of suspension beams is 120W.

Embodiment 3

[0016] Embodiment 3: The difference between this example and Embodiment 1 is that the motion speed of the stainless steel roller conveyor belt slows down to some extent. By adjusting the rotation frequency of the reduction motor, the motion speed of the stainless steel roller conveyor belt becomes 0.10m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com