Nondestructive testing method of furnace body lining based on impact elastic waves

An impact elasticity, non-destructive testing technology, applied in the use of sonic/ultrasonic/infrasonic waves to analyze solids, measurement devices, and the use of ultrasonic/sonic/infrasonic waves, etc., can solve problems such as non-destructive testing of difficult furnace linings, and achieve the effect of ensuring objectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]The non-destructive testing method for furnace lining based on shock elastic waves includes the following steps: (a) determining the position of the measuring point and the excitation position on the surface of the furnace body; (b) installing a sensor at the position of the measuring point, and installing an excitation device at the excitation position ; start the vibration excitation device to excite vibration, collect the vibration signal through the sensor; (c) analyze the vibration signal, save the analysis conditions and analysis results; (d) adopt the same vibration excitation device, after a period of time, in the step ( Steps (b) to (c) are repeated at the same measuring point position and excitation position in a), and the analysis is carried out using the same analysis conditions as in step (c); (e) trend analysis results obtained at different times Through the analysis, the change trend of the lining thickness of the furnace body can be obtained, and the safet...

Embodiment 2

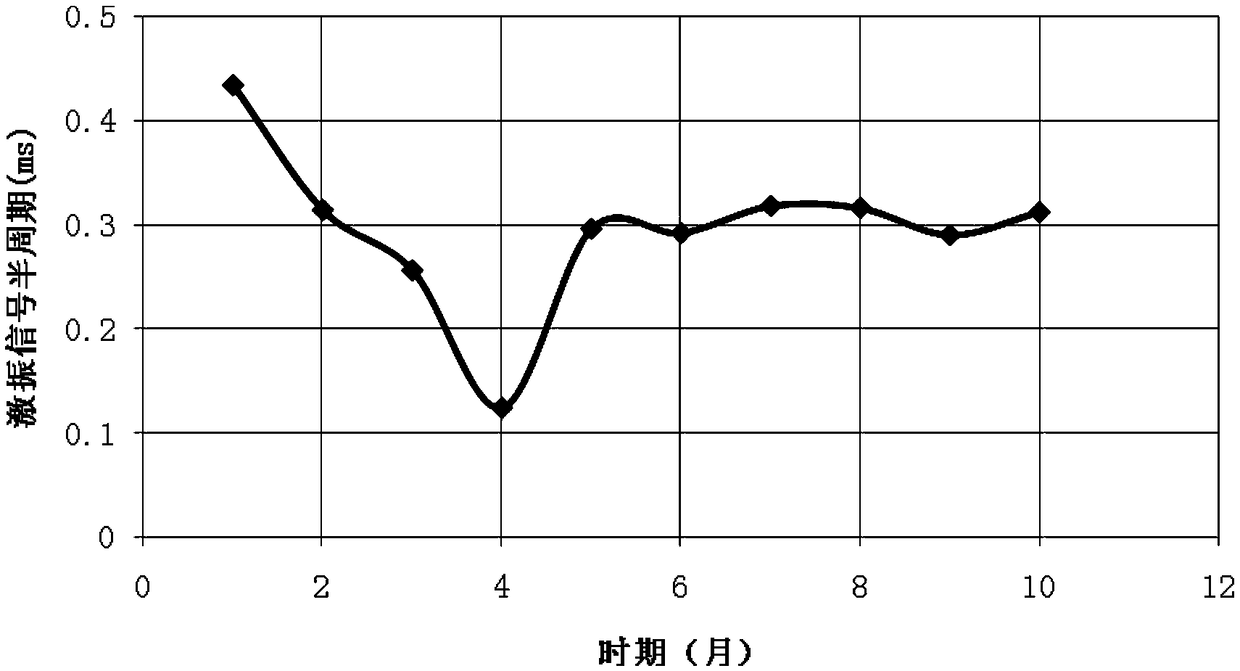

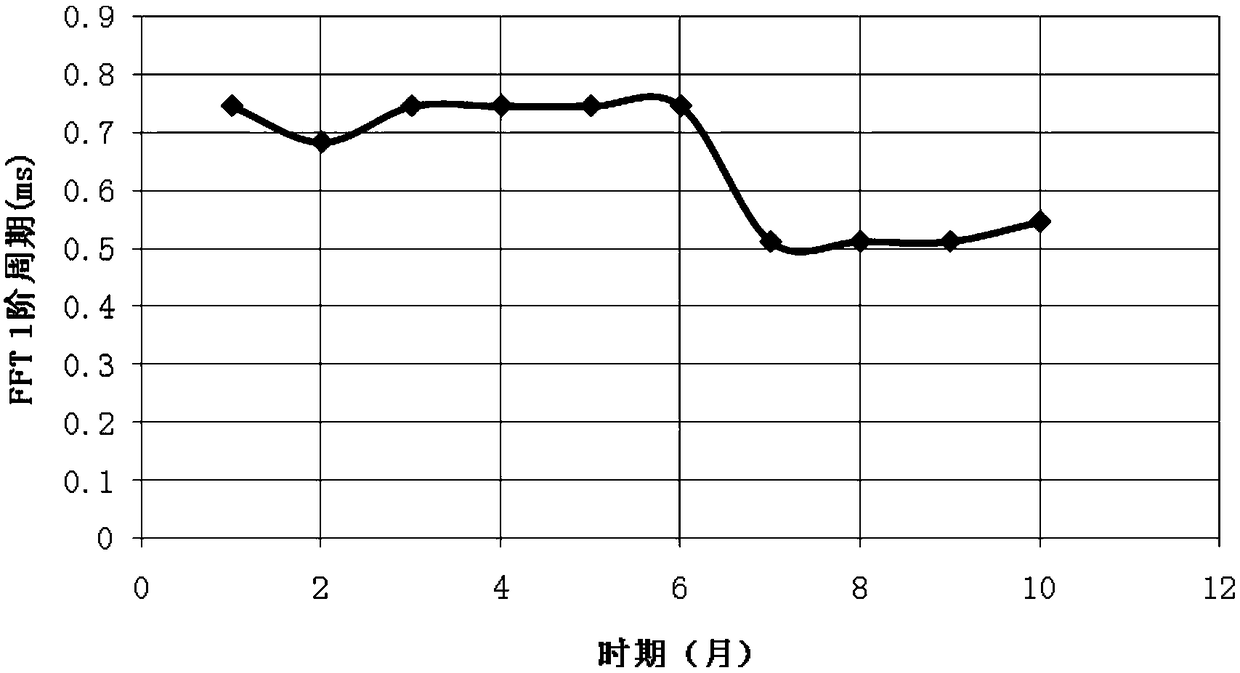

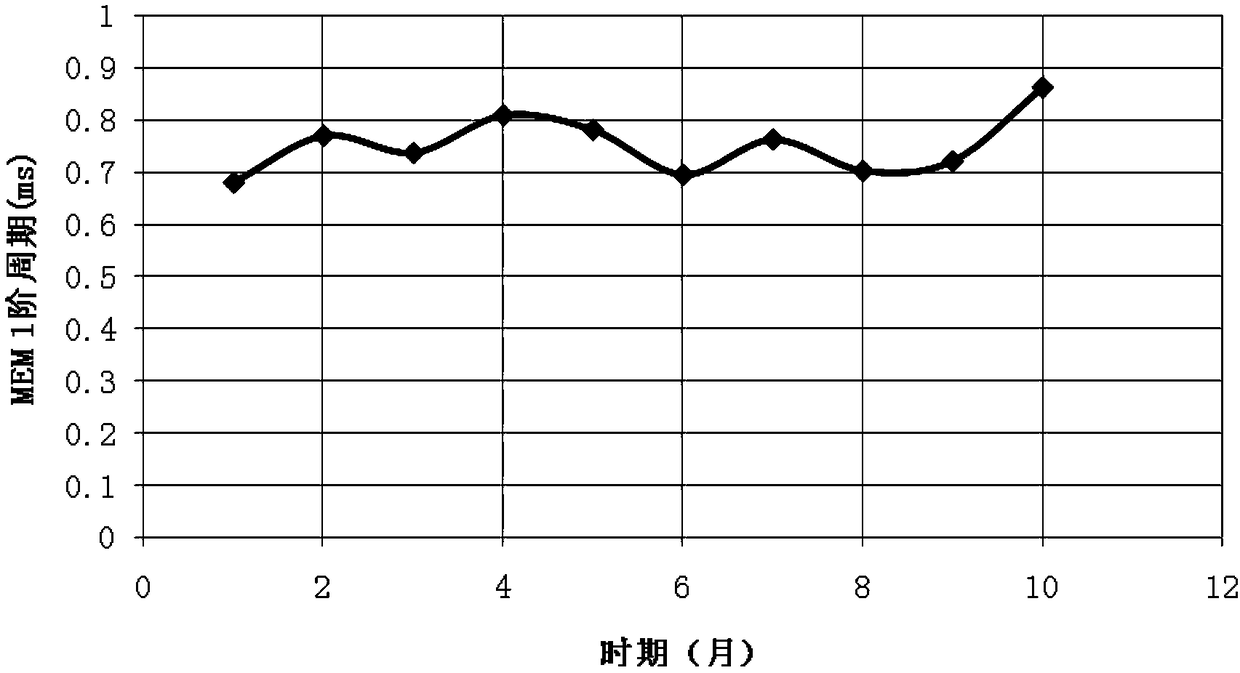

[0033] Based on the shock elastic wave-based nondestructive testing method for furnace body lining, on the basis of Example 1, the analysis in step (c) includes: correlation analysis with vibration signals as basis functions, fast Fourier analysis, and maximum entropy analysis. The analysis includes calculating characteristic parameters in correlation analysis, fast Fourier analysis, and maximum entropy analysis with the vibration signal as the basis function. The characteristic parameters include one or more of detection items, measuring point locations, test date, analysis date, number of vibrations, and statistical parameters of data obtained from different vibration times for each test. The number of excitations in the characteristic parameters includes each excitation: the maximum amplitude of the excitation signal; the first half-wave time of the excitation signal, the moment corresponding to the highest order in the fast Fourier analysis, and the second highest level of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com