Preparation method of cement dispersing agent with clay adaptability and viscosity reduction effect

A cement dispersant and adaptability technology, which is applied in the field of concrete admixtures, can solve the problems of poor adaptability of clay and high viscosity of concrete, and achieve the effects of improved adaptability of clay, low production energy consumption and strong electrostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

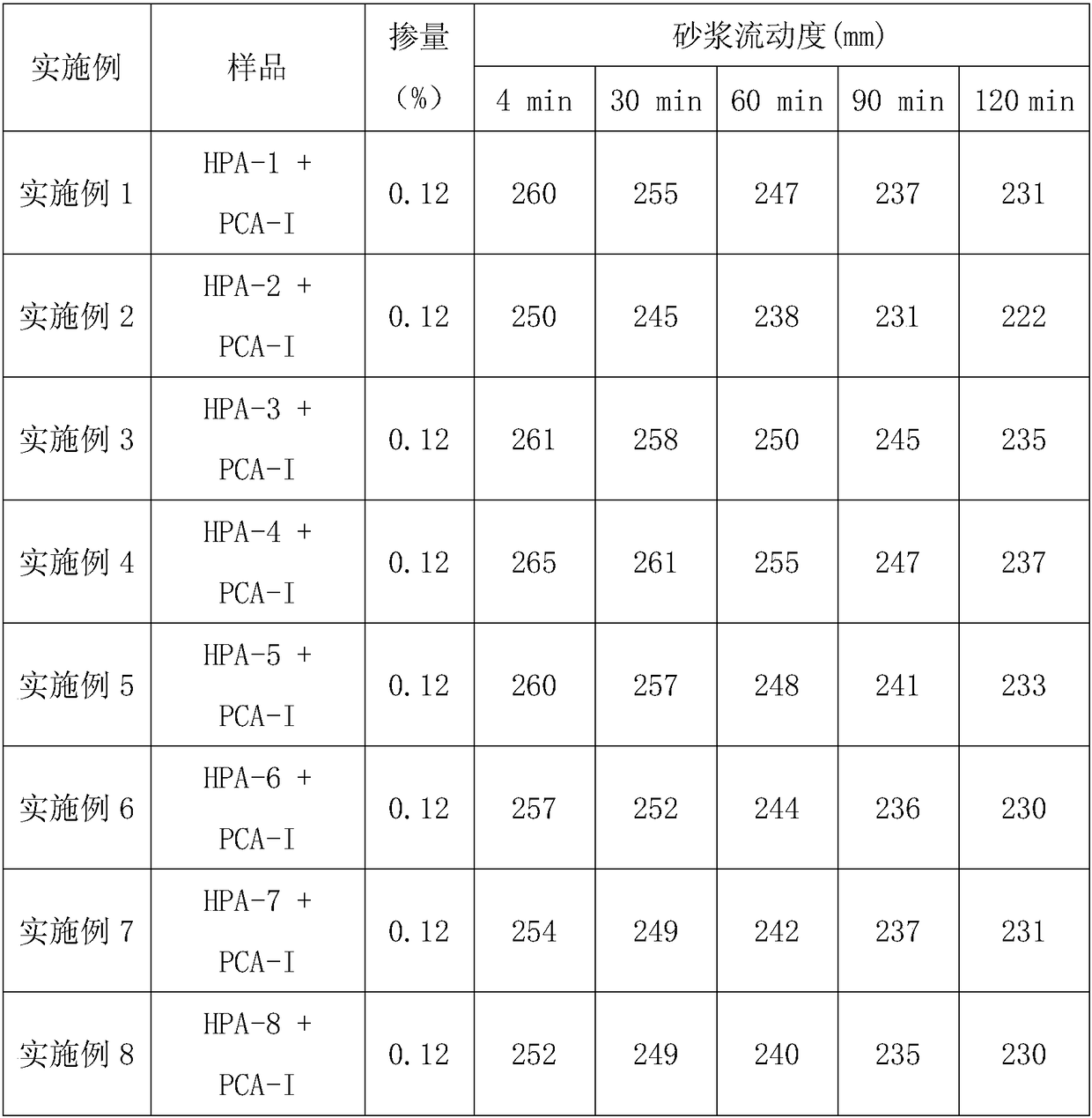

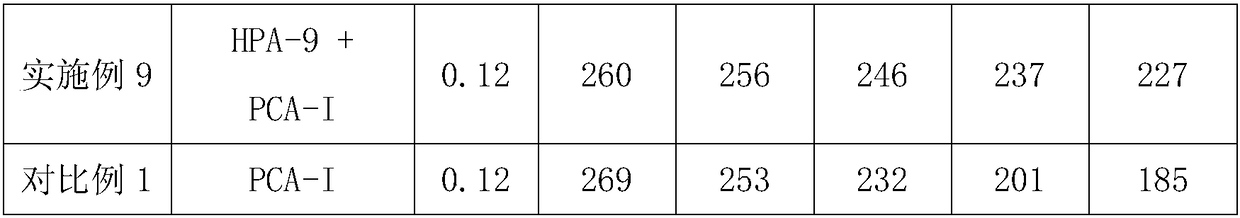

Examples

preparation example 1

[0036] Preparation of Intermediate Product C-1 by Stepwise Addition of Amino-Terminal Polyethers and Diglycidyl Ethers

[0037] Weigh 100 parts of amino polyether (Mn=1000) (code-named ATPE-1000) and 17.42 parts of ethylene glycol diglycidyl ether into a four-necked flask equipped with stirring and temperature measurement, pass nitrogen gas-vacuum three times, remove The air in the system was slowly heated to 100°C with stirring, and after 5 hours of heat preservation reaction, 5 parts of aminopolyether ATPE-1000 was added, and after 2 hours of continuous reaction, it was cooled to room temperature to obtain a brown solid C-1. The weight average molecular weight determined by gel chromatography was 12300.

[0038] Similarly, the following stepwise addition polymerization intermediates C-2 to C-9 were prepared.

preparation example 2

[0040] C-2: Weigh 100 parts of amino polyether ATPE-1000 (Mn=1000) and 20.23 parts of 1,4-butanediol diglycidyl ether into a four-necked flask equipped with stirring and temperature measurement, blow nitrogen-pump Vacuum three times to remove the air in the system, and slowly raise the temperature to 120°C while stirring. After 7 hours of heat preservation reaction, add 2 parts of amino polyether ATPE-1000, continue the reaction for 2 hours, and cool to room temperature to obtain a brown solid. C-2, the weight average molecular weight determined by gel chromatography is 15600.

preparation example 3

[0042] C-3: Weigh 100 parts of amino polyether ATPE-1000 (Mn=1000) and 22.22 parts of 1,3-benzenediol diglycidyl ether into a four-necked flask equipped with stirring and temperature measurement, and nitrogen-pump Vacuum three times to remove the air in the system, and slowly raise the temperature to 90°C while stirring. After 10 hours of heat preservation reaction, add 2 parts of aminopolyether ATPE-1000, continue the reaction for 2 hours, and cool to room temperature to obtain a brown solid C-3, the weight average molecular weight determined by gel chromatography is 23000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com