Stalk fiber toughening mortar and preparation method thereof

A straw fiber and mortar technology is applied in the field of straw fiber toughened mortar and its preparation, which can solve problems such as poor toughness of the mortar, and achieve the effects of enhancing adhesion performance, inhibiting generation and growth, and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

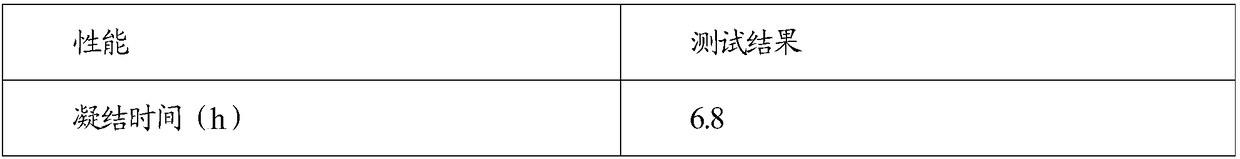

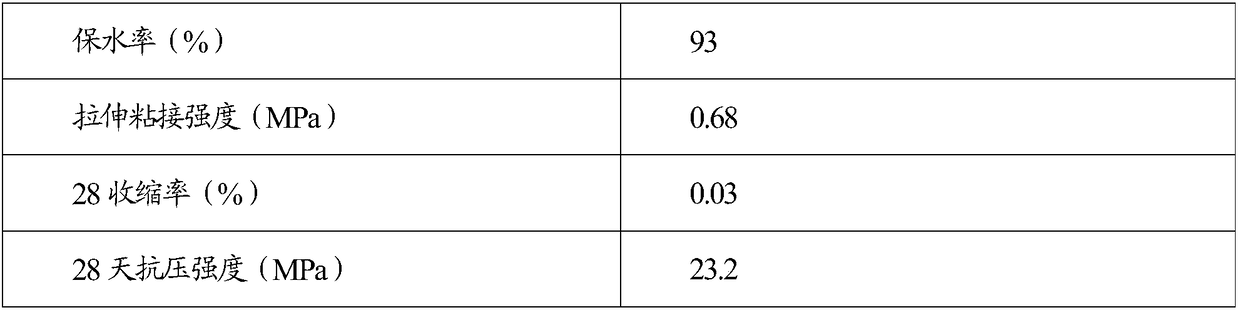

Embodiment 1

[0018] A straw fiber toughened mortar, comprising the following components in parts by weight: 20 parts of ordinary Portland cement, 50 parts of perlite, 15 parts of iron tailings, 15 parts of waste porcelain powder, 15 parts of slag powder, 8 parts of straw fiber, 1 part of starch ether, 0.5 part of hydroxypropyl cellulose, 3 parts of polyvinyl alcohol, 1 part of styrene-acrylic emulsion, and 2 parts of methyl cellulose ether.

[0019] The stalk fiber is obtained by drying corn stalks whose length is less than or equal to 5nm after shearing treatment, soaking in 8% sodium hydroxide for 10 hours.

[0020] The preparation method of the straw fiber toughened mortar comprises the following steps: accurately weighing various raw materials according to the weight ratio, first mixing ordinary Portland cement, perlite, iron tailings powder, waste porcelain powder, and starch ether evenly, Then, during the stirring process, straw fiber, hydroxypropyl cellulose ether, polyvinyl alcohol...

Embodiment 2

[0026] A straw fiber toughening mortar, comprising the following components in parts by weight: 40 parts of ordinary Portland cement, 70 parts of perlite, 35 parts of iron tailings, 30 parts of waste porcelain powder, 20 parts of slag powder, straw 20 parts of fiber, 1.5 parts of starch ether, 2 parts of hydroxypropyl cellulose, 8 parts of polyvinyl alcohol, 6 parts of styrene-acrylic emulsion, and 4 parts of methyl cellulose ether.

[0027] The stalk fiber is obtained by drying corn stalks whose length is less than or equal to 5nm after shearing treatment, soaking in 8% sodium hydroxide for 10 hours.

[0028] The preparation method of the straw fiber toughened mortar comprises the following steps: accurately weighing various raw materials according to the weight ratio, first mixing ordinary Portland cement, perlite, iron tailings powder, waste porcelain powder, and starch ether evenly, Then, during the stirring process, straw fiber, hydroxypropyl cellulose ether, polyvinyl al...

Embodiment 3

[0033] A straw fiber toughening mortar, comprising the following components in parts by weight: 25 parts of ordinary Portland cement, 55 parts of perlite, 20 parts of iron tailings, 20 parts of waste porcelain powder, 15 parts of slag powder, straw 10 parts of fiber, 1.2 parts of starch ether, 1 part of hydroxypropyl cellulose, 4 parts of polyvinyl alcohol, 2 parts of styrene-acrylic emulsion, and 3 parts of methyl cellulose ether.

[0034] The stalk fiber is obtained by drying corn stalks whose length is less than or equal to 5nm after shearing treatment, soaking in 8% sodium hydroxide for 10 hours.

[0035] The preparation method of the straw fiber toughened mortar comprises the following steps: accurately weighing various raw materials according to the weight ratio, first mixing ordinary Portland cement, perlite, iron tailings powder, waste porcelain powder, and starch ether evenly, Then, during the stirring process, straw fiber, hydroxypropyl cellulose ether, polyvinyl alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com