Cyclically-adjustable automatic paint spraying and drying equipment

A drying equipment and automatic painting technology, applied in the painting room, spraying device, etc., can solve the problems of inability to spray-dry cycle operation, poor product surface quality, low pass rate, etc., to reduce manual labor intensity and improve product quality. Stable, consistent drying results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to fully understand the technical solutions and beneficial effects of the present invention, further description will be given below in conjunction with specific examples.

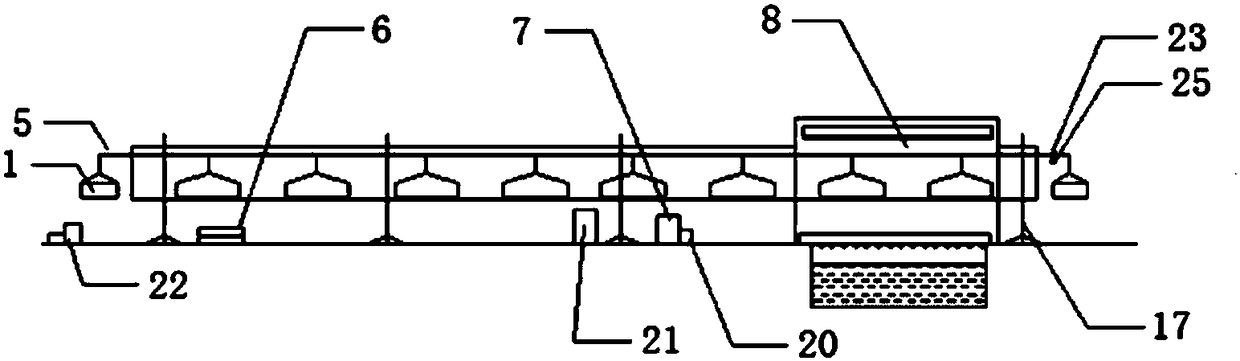

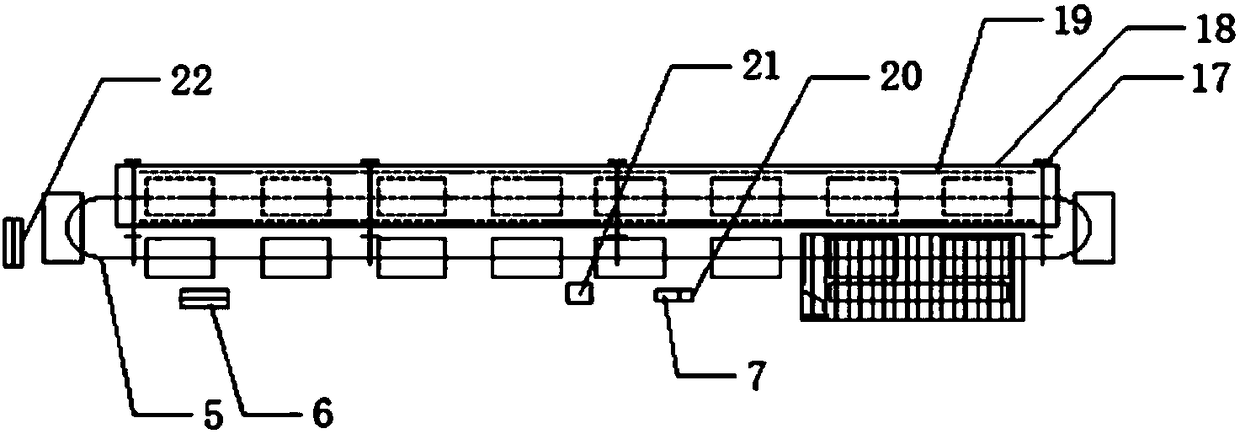

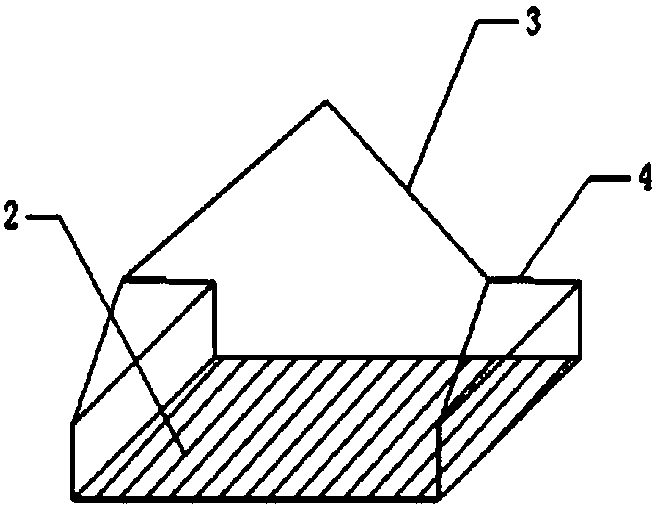

[0022] Such as Figure 1-6 A cycle-adjustable automatic paint drying equipment is shown, including several turnover baskets (1), metal mesh (2), booms (3), hanging ropes (4), endless transmission chains (5), feeding Ladder (6), speed control box (7), spray booth (8), entrance window (9), exit window (10), door (11), painting pedal (12), circulating fan motor (13), filter Net (14), isolation net (15), circulating water (16), column (17), drying room (18), electric heating wire (19), temperature control box (20), generator (21), Reclaiming ladder (22), engine oil funnel (23), support (24), engine oil cup (25), tray (26), suspension hook (27). Wherein, the endless transmission chain (5) is supported by columns, and different parts of the transmission chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com