Assembly system for stretcher

An assembly system and a stretcher technology, applied in the field of parts installation, can solve the problems of increasing the looseness of the fabric at the punching place, increasing the conveying and processing path of the cloth, and reducing the processing accuracy of the cloth, so as to prevent loosening, improve the processing accuracy, and ensure the quality of the finished product. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

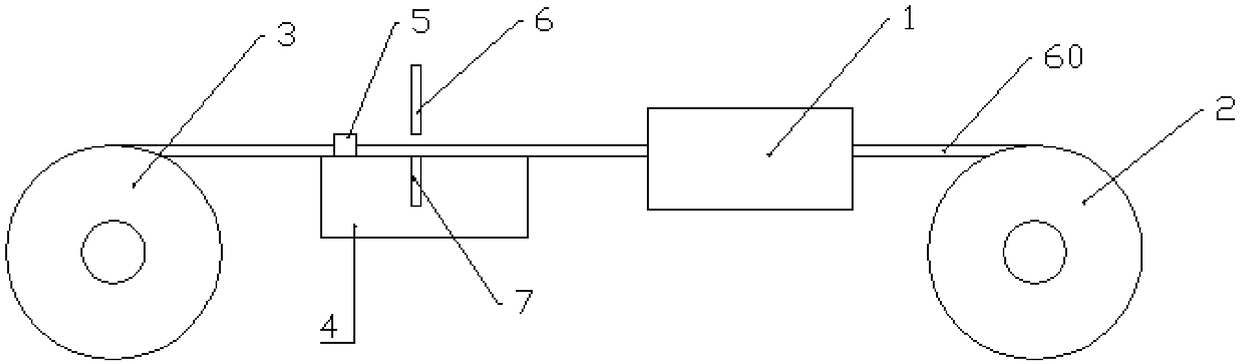

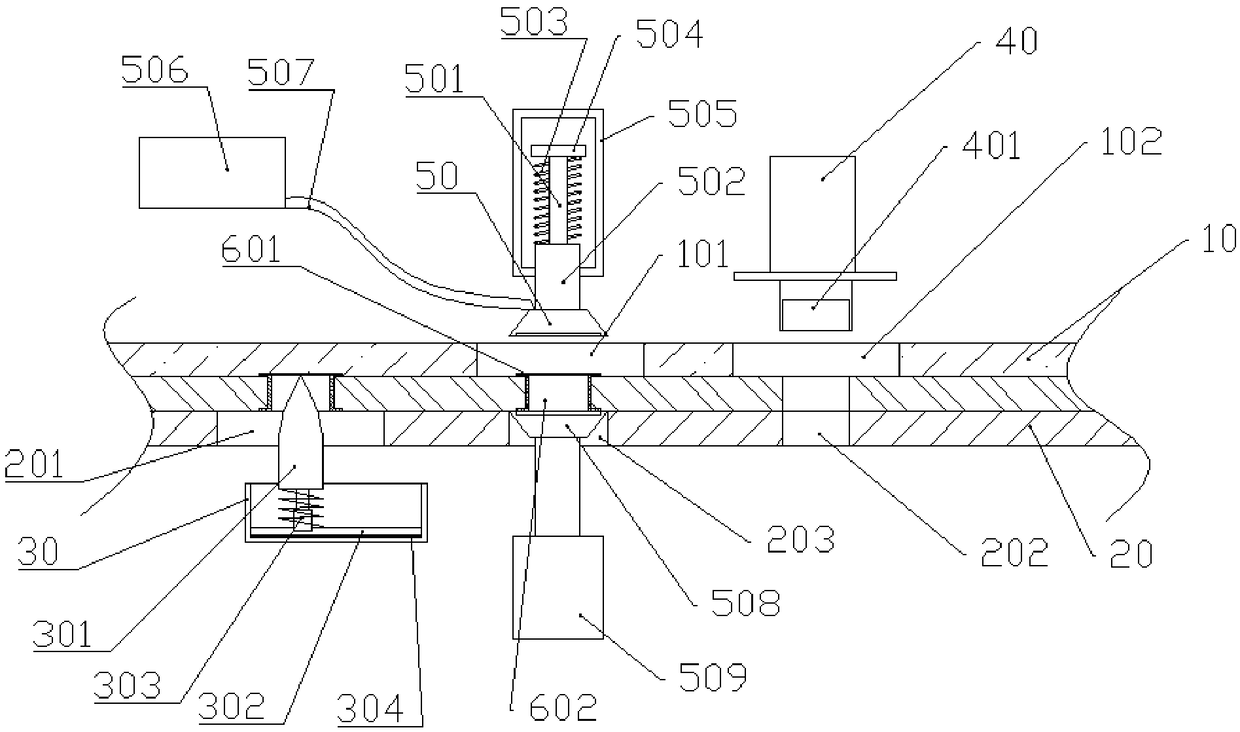

[0021] The reference signs in the drawings of the description include: cloth punching device 1, unwinding roller 2, winding roller 3, cutting table 4, cloth clamping block 5, cutting knife 6, cutting groove 7, first limiting plate 10 , the first installation hole 101, the second through hole 102, the second limit plate 20, the first through hole 201, the third through hole 202, the second installation hole 203, the installation box 30, the moving rod 301, the slide rail 302, Spring bar 303, electromagnet 304, puncher 40, punching knife 401, suction cup 50, ejector rod 501, jacking block 502, clip spring 503, fixed block 504, pull bar 505, negative pressure machine 506, suction duct 507, Support table 508, cylinder 509, cloth 60, buckle cap 601, buckle 602.

[0022] The embodiment is basically as attached figure 1 And attached figure 2 Shown: an assembly system for a stretcher, including a clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com