A catalyst with open hollow sphere structure and its preparation method and application

A technology of structural catalysts and hollow spheres, applied in structural parts, electrochemical generators, nanotechnology for materials and surface science, etc., can solve the complex synthesis process of templates or nanocrystal seeds, hollow structure damage, and many operation steps. and other problems, to achieve the effect of improving utilization efficiency, uniform shape and size, and high electrochemically active surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

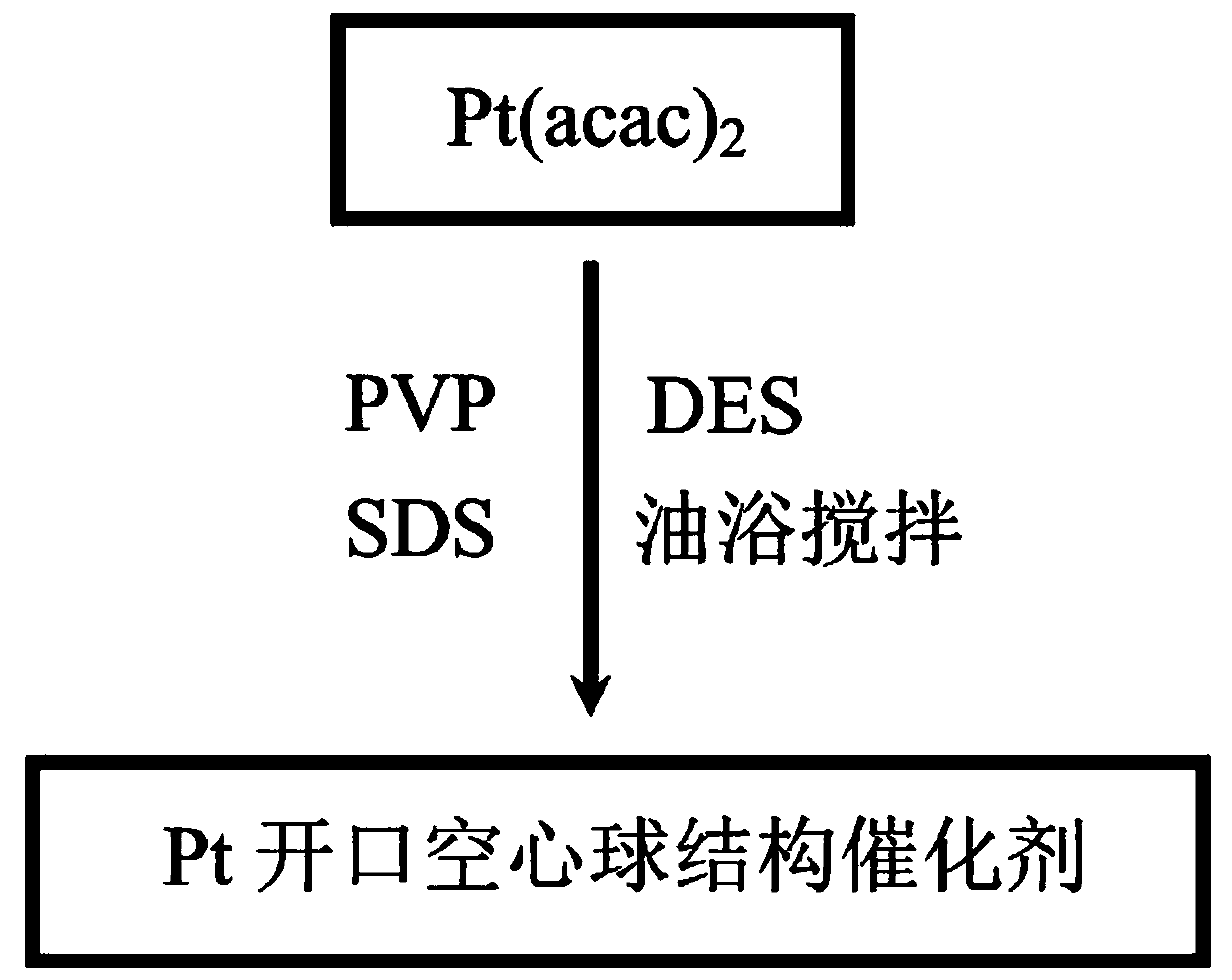

[0017] refer to figure 1 , a preparation method of a Pt open hollow sphere structure catalyst, a one-step chemical reduction method to prepare a Pt open hollow sphere structure catalyst, specifically: add 8 mL of choline chloride / ethylene glycol deep eutectic solvent to a container 4.0 mg Pt(acac) 2 , 25 mg sodium lauryl sulfate and 30 mg polyvinylpyrrolidone (PVP), sonicate at room temperature for 10 minutes and magnetically stir for 5 minutes, then stir the resulting suspension at 110°C-160°C for 0.5-5 hours, After the reaction product is centrifuged and washed, the Pt open hollow sphere structure catalyst can be obtained.

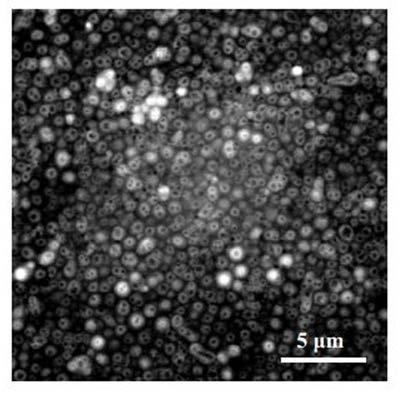

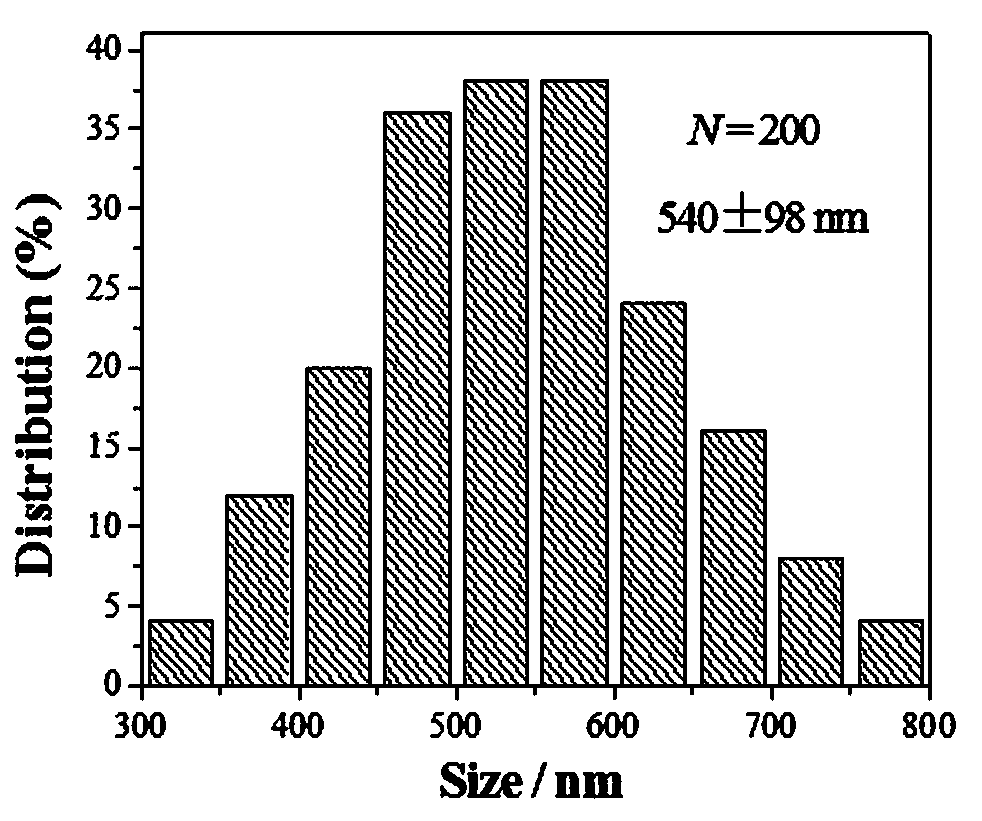

[0018] SEM analysis showed that most of the prepared catalyst particles showed a spherical structure with a hollow center and an external opening, wherein the catalyst yield of the open hollow sphere structure was as high as 90%, and the average particle size was 540 nm, confirming that the Pt open hollow spheres synthesized in this example Structured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com