Wire tensioning device

A tensioning device and wire technology, which is applied in the field of wire tensioning devices and transposition wire equipment, can solve the problems of affecting the processing of transposition process, the effect of tension is not obvious, and the wires are prone to jumping wires, etc., and achieve the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings.

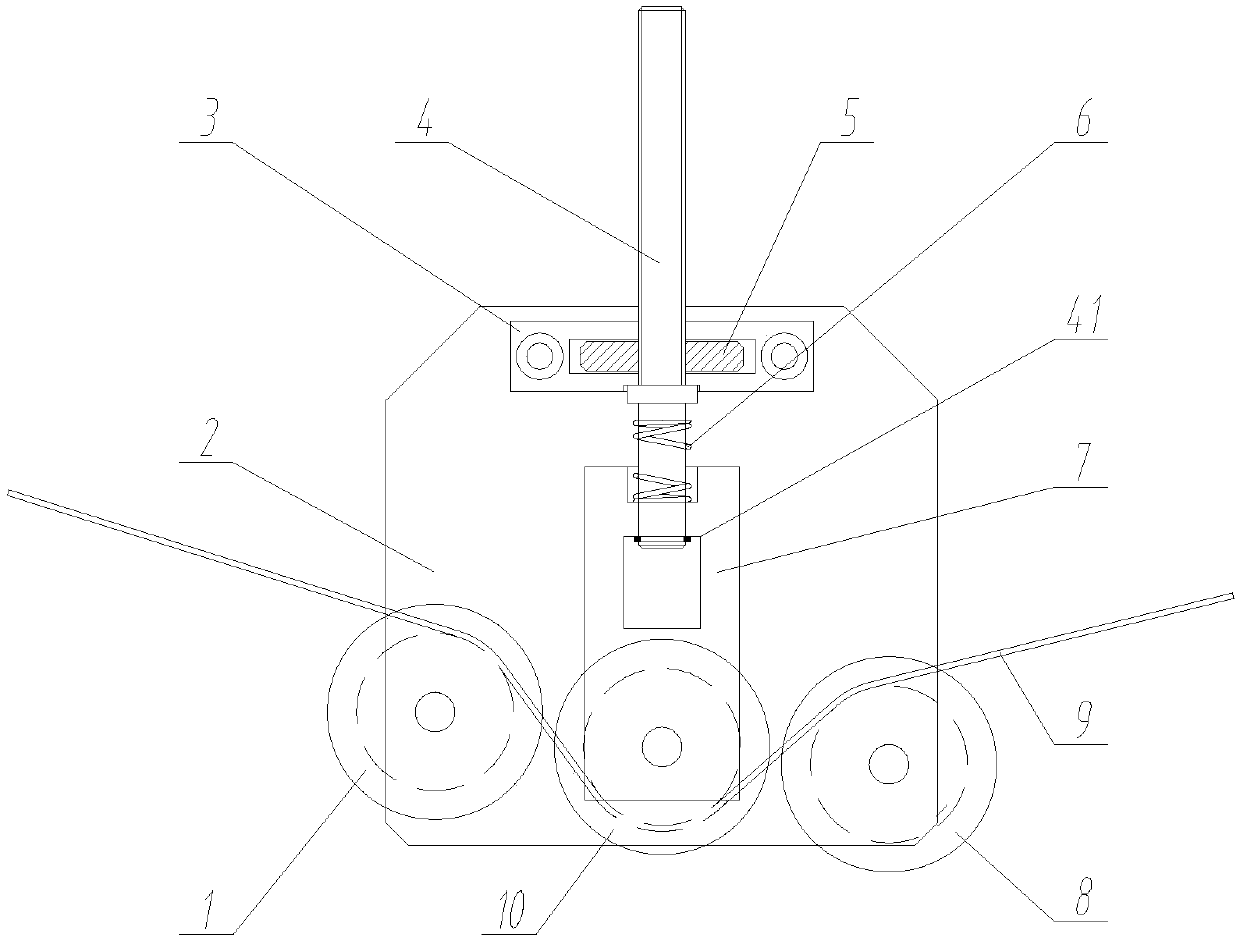

[0014] Such as figure 1 As shown, this wire tensioning device includes a fixed plate 2, a left roller 1, a middle roller 10, a right roller 8 and a central shaft 4;

[0015] The left roller 1 is rotatably mounted on the left front end of the fixed plate 2, the right roller 8 is rotatably mounted on the right front end of the fixed plate 2, and the middle roller 10 is mounted on the connecting block 7 and located at the middle front end of the fixed plate 2. The lower part of the central shaft 4 is slidably mounted on the connecting block 7 up and down, and the lower end is provided with a limit ring 41. The lower part of the central shaft 4 is sleeved with an elastic device 6 whose one end is in contact with the middle of the central shaft 4 and the other end Contact with the upper end of the connecting block 7;

[0016] The upper part of the central shaft 4 has a threaded structure and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com