Loose media permeation grouting simulation experiment method

A simulation test and loose body technology, applied in the direction of permeability/surface area analysis, using stable tension/pressure to test material strength, measuring devices, etc., can solve the difficulties in the analysis process of loose body consolidation form and the difficulty in monitoring the slurry diffusion process , can not reproduce the stress environment and other problems, to achieve the effect of dynamic tracing, elimination of boundary effects, and convenient operation

Active Publication Date: 2018-05-18

CHINA UNIV OF MINING & TECH

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the existing laboratory loose body grouting simulation test devices mostly use filling grouting tests, which cannot reproduce the in-situ stress environment, and the analysis process of the loose body consolidation form after grouting consolidation is also very diffic

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

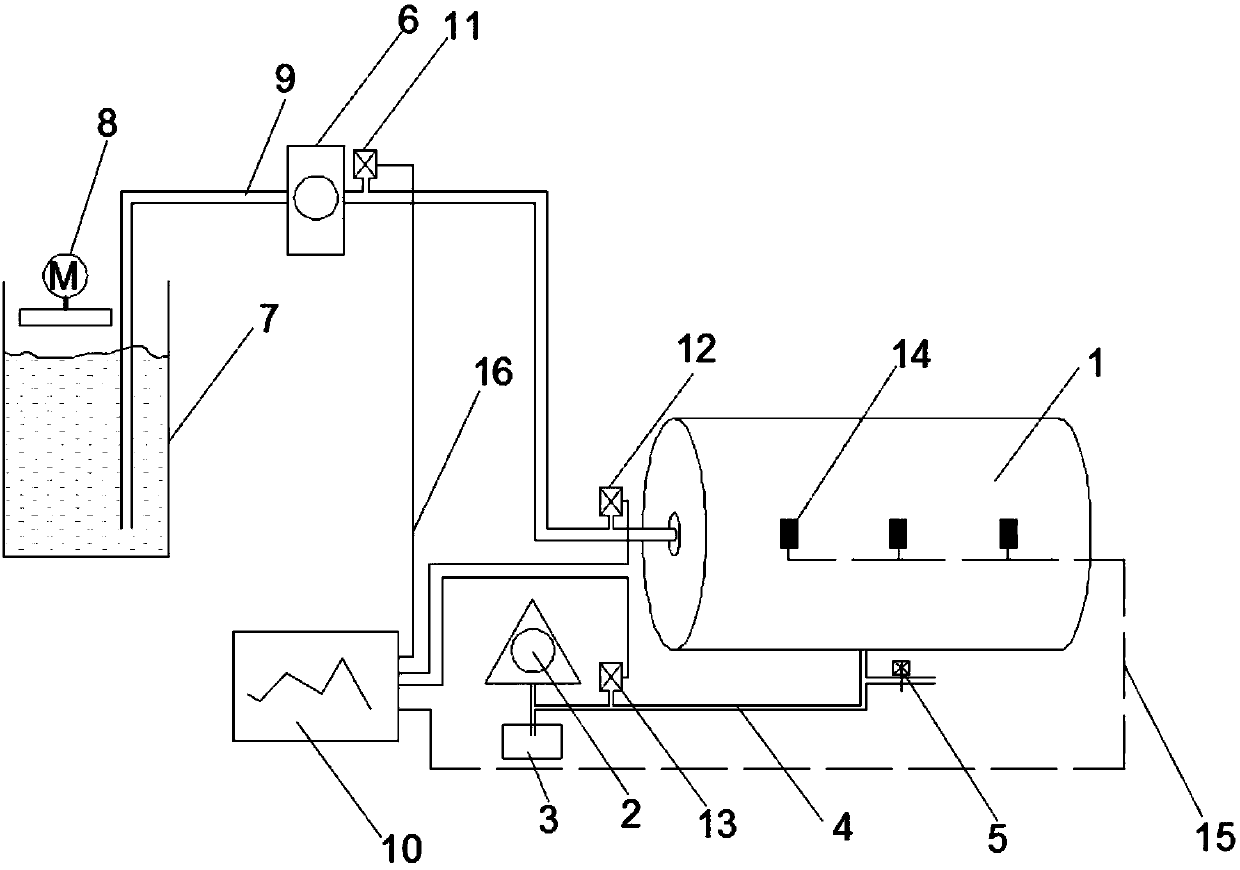

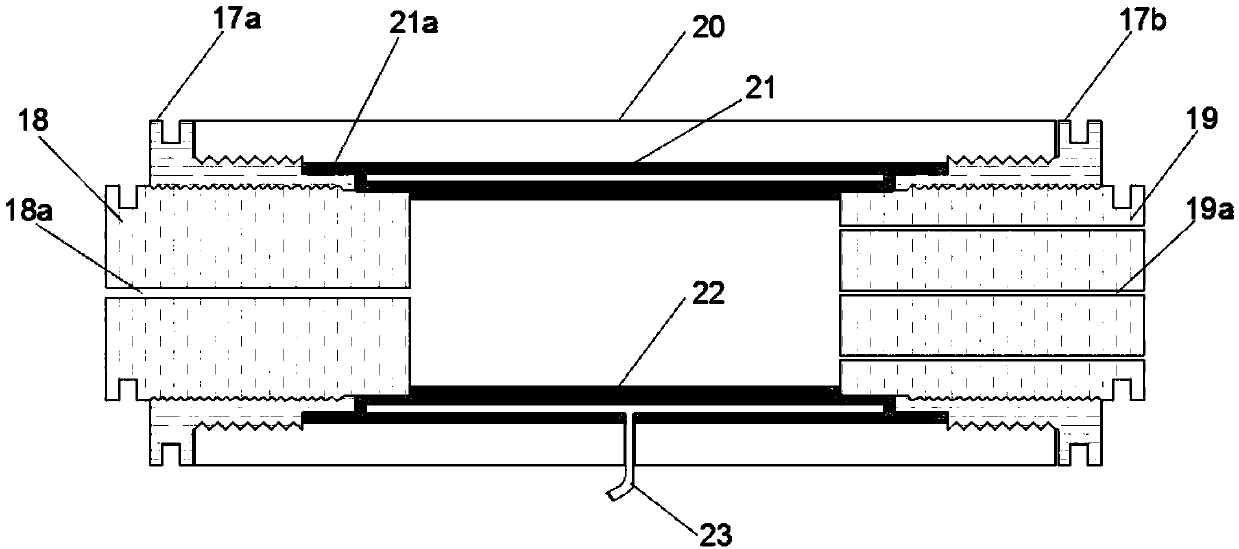

The invention discloses a loose media permeation grouting simulation experiment method. A constant-pressure confining pressure pump is utilized to inject high-pressure water into a rubber water bag sleeve via a water hole to provide confining pressure, and the provided confining pressure is higher than grouting pressure; during grouting, a rubber valve sleeve depends on the confining pressure to tightly wrap loose media, loose media grouting is definitely permeation grouting under the condition that the confining pressure is higher than the grouting pressure, and therefore the influence of grouting methods, such as compaction grouting and fracturing grouting, on grouting effect is prevented. The loose media permeation grouting simulation experiment method is convenient to operate, and cantruly simulate permeation grouting reinforcement for the loose media, the rubber valve sleeve is utilized to wrap the loose media, and by means of the rubber water bag sleeve, pressure is applied on the loose media to simulate a geostress environment; by regulating the pressure of the constant-pressure confining pressure pump and a grouting pump, the confining pressure is higher than the groutingpressure, so that the loose media permeation grouting process can be simulated; after grouting is completed, the solidified loose media wrapped by the rubber valve sleeve can be completely taken out for study; and an experimental result obtained by the method has guiding significance for an actual engineering design.

Description

technical field [0001] The invention relates to a loose body seepage grouting simulation test method, which is suitable for laboratory simulation of loose body seepage grouting. Background technique [0002] Infiltration grouting of loose bodies is a common problem in geotechnical engineering. The law of grout diffusion during grouting and the mechanical properties of loose bodies after grouting are the key to the practice of grouting reinforcement of loose bodies. During on-site construction, loose bodies are mostly in a certain in-situ stress field, especially in deep geotechnical engineering. Therefore, it is of great significance to realize the simulation of loose body grouting test laboratory for actual loose body grouting projects. [0003] However, the existing laboratory loose body grouting simulation test devices mostly use filling grouting tests, which cannot reproduce the in-situ stress environment, and the analysis process of the loose body consolidation form aft...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N15/08G01N3/08

CPCG01N3/08G01N15/08G01N2015/0813G01N2203/0019G01N2203/0252

Inventor 李桂臣孙长伦崔光俊

Owner CHINA UNIV OF MINING & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com