A wide Mach number high enthalpy tube wind tunnel driving tube body

A technology of Mach number and driving tube, which is applied in the field of driving tube body of wide Mach number and high enthalpy tube wind tunnel, which can solve the problem that it is difficult to reproduce the flight environment in pulsed wind tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

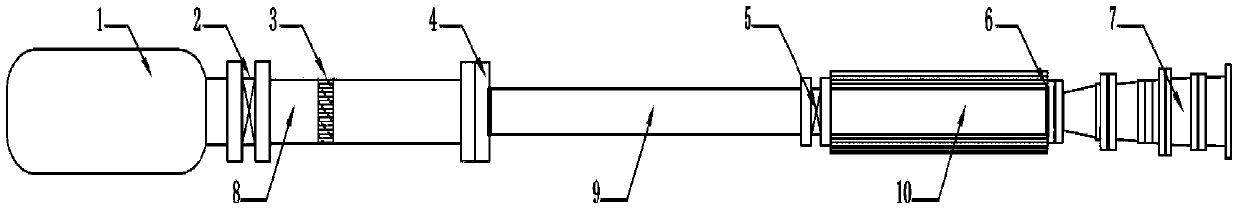

[0017] like figure 1 As shown, the wide Mach number high enthalpy tube wind tunnel drive technology proposed by the present invention involves a drive tube body including: a high pressure drive chamber 1 , a slow piston drive section 8 , a cold tube section 9 and an external preheating section 10 . Wherein, the moving piston 3 is contained in the slow piston driving section 8 .

[0018] The high-pressure drive chamber 1 and the slow piston drive section 8 are located upstream of the drive pipe body and are isolated by the upstream diaphragm 4 . During the compression process of the piston 3, the pressure regulating valve 2 is slowly opened, and the pressure difference on both sides of the piston 3 gradually increases. The movement process of piston 3 is determined by the following relational formula:

[0019]

[0020]

[0021] Among them, X(t) is the axial position of piston 3 at time t, V(t) is the moving speed of piston 3 at time t, m is the mass of piston 3, A is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com