Strain sensor with high sensitivity and large strain response and preparation method thereof

A strain sensor and sensor technology, applied in the field of strain sensors, can solve the problems of restricting the wide popularization and application of materials, low high stretchability, low sensitivity, etc., and achieve large strain sensing range, low production cost, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

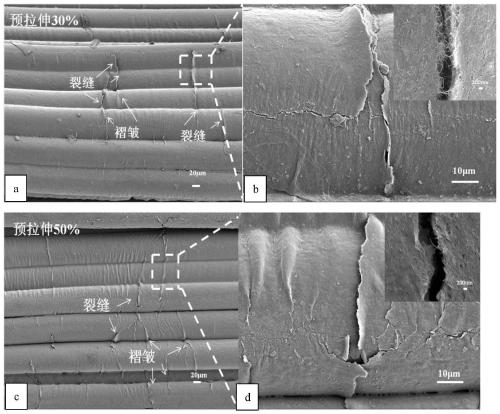

[0053] In this embodiment, the polyurethane fiber is used as the matrix, and the carbon nanotube ink is used as the conductive coating. The fiber is swelled in DMF, and then the conductive ink is evenly distributed on the surface of the fiber in the ultrasonic process to obtain a strain sensor. Finally, the strain sensor is tested on the electronic universal testing machine In the process, the strain sensor with crack-fold microstructure is prepared by applying stress; the specific process is as follows:

[0054] (1) Cut the polyurethane fiber into a length of 4 cm, and ultrasonically clean it with absolute ethanol and deionized water for 10 minutes in an ultrasonic cleaner to remove surface impurities; wherein the polyurethane fiber used has a size of 2500D and a diameter of 500 μm;

[0055] (2) Put the polyurethane fibers cleaned in step (1) into the DMF solution, swell for 1h, then put the swollen polyurethane fibers into the carbon nanotube ink dispersion liquid successivel...

Embodiment 2

[0059] The first three steps of the preparation method are the same as in Example 1. When the crack-wrinkle microstructure is constructed in the fourth step, a 50% strain is applied at a rate of 2mm / min, and then returns to the original position at the same rate; The two ends of the polyurethane fiber covered with carbon nanotube coating are connected with copper tape as electrodes, and the strain sensor with microstructure is obtained.

Embodiment 3

[0061] The first three steps of the preparation method are the same as in Example 1. When the crack-wrinkle microstructure is constructed in the fourth step, a strain of 70% is applied at a rate of 2 mm / min, and then returns to the original position at the same rate; The two ends of the polyurethane fiber covered with carbon nanotube coating are connected with copper tape as electrodes, and the strain sensor with microstructure is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com