High temperature and high pressure kettle large gap compensation type sealing device

A sealing device, high temperature and high pressure technology, applied to the sealing of the engine, engine components, mechanical equipment, etc., to achieve the effects of high reliability, simple structure, and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

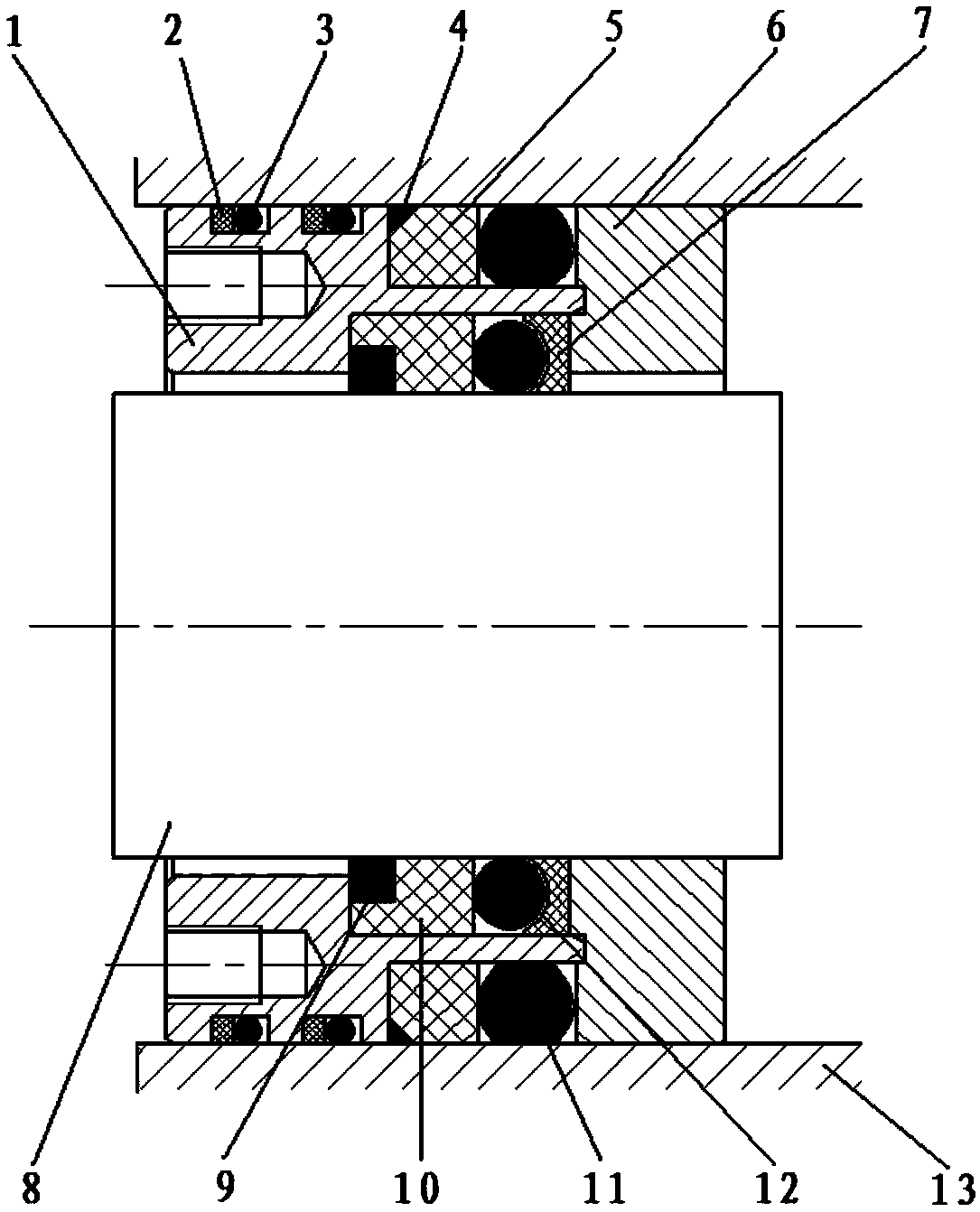

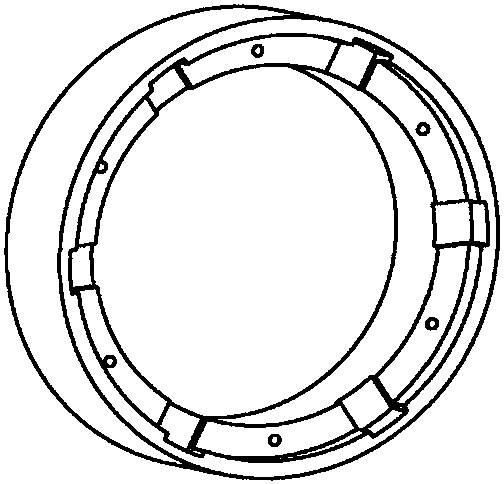

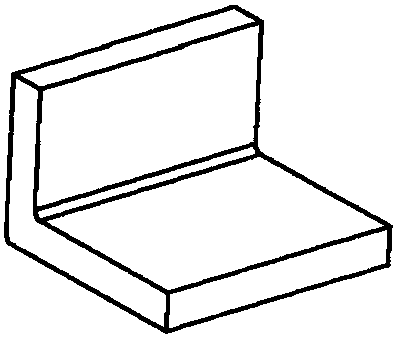

[0013] The present invention is a high-temperature autoclave large-gap compensation type sealing device, which includes a sealing groove-shaped member 1, a baffle 6, an auxiliary O-shaped sealing combination, an outer main sealing structure, and an inner sealing structure; wherein, the sealing groove is 1 The function of installing and fixing the sealing ring, and is designed with threaded holes for disassembly; the baffle 6 plays the role of limiting and pre-tightening; the auxiliary O-ring seal combination is composed of the outer auxiliary PTFE retaining ring 2 and the fluorine rubber O-ring 3, acting as an auxiliary sealing Function; The outer main sealing structure includes the outer cone-shaped aluminum flow stopper 4, the outer PTFE retaining ring 5, and the outer large diameter O-ring 11. When pressure occurs in the kettle, the outer large diameter O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com