Pump body assembly and compressor

A component and pump body technology, applied in pump components, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve problems such as insufficient air supply and poor energy efficiency of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

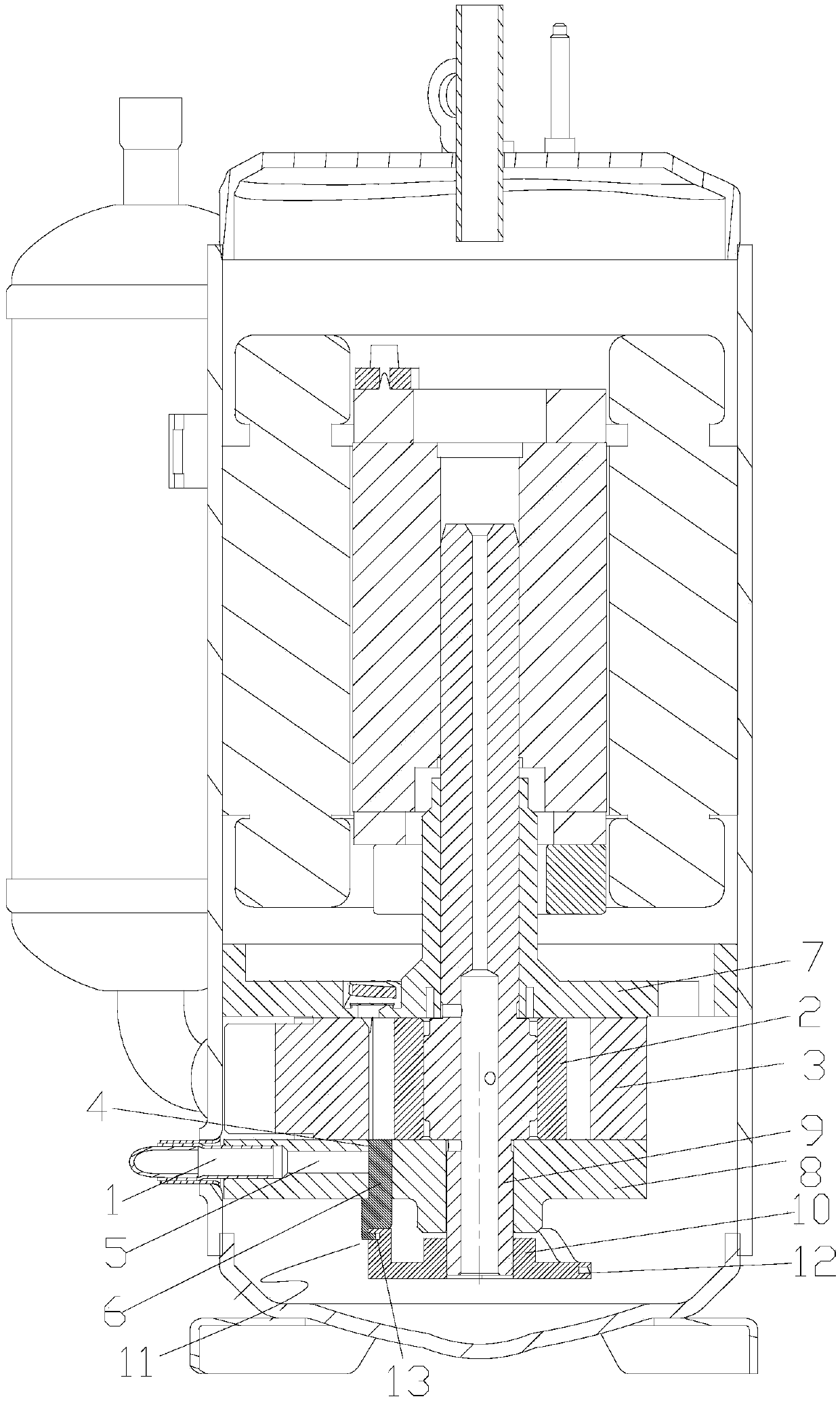

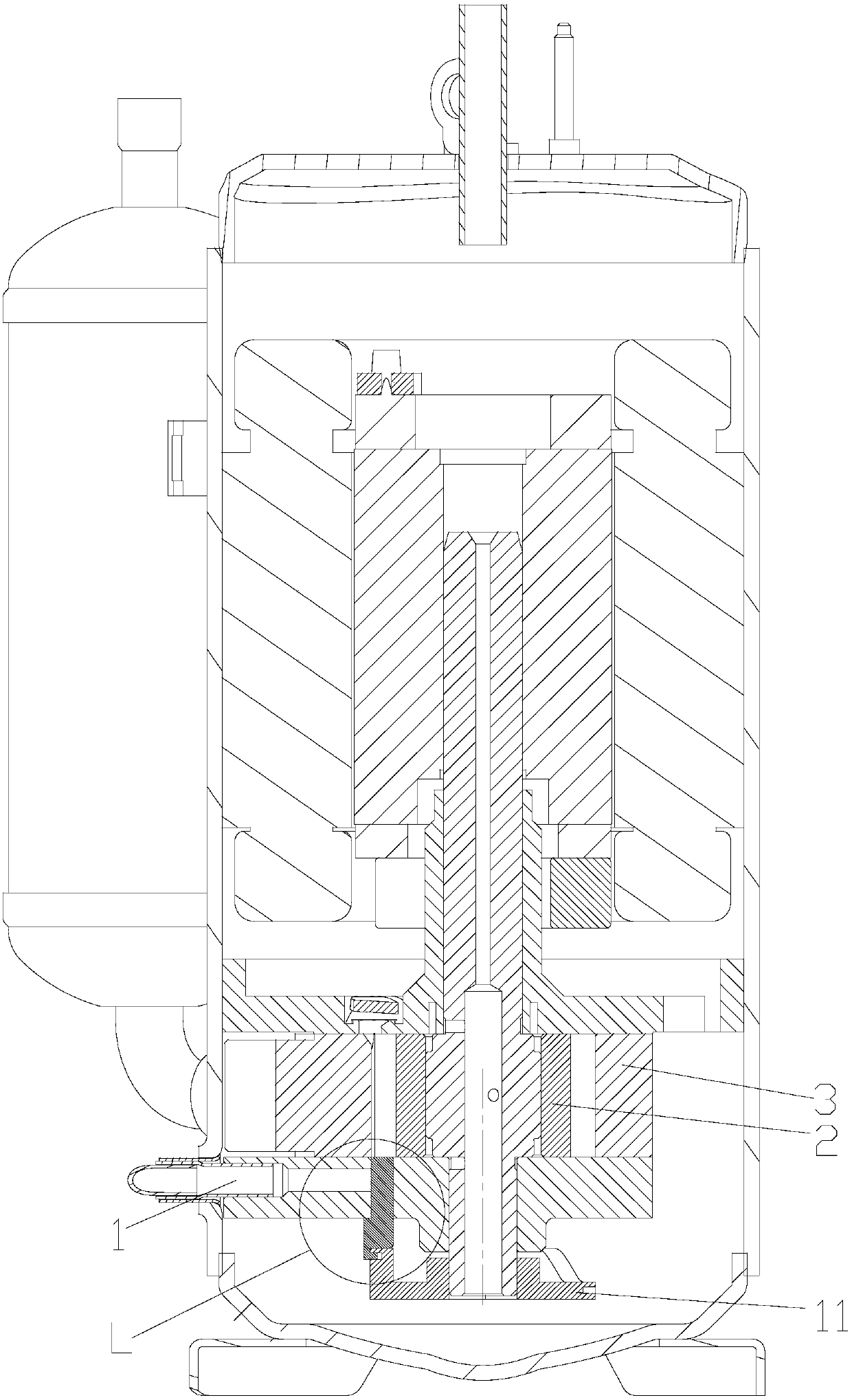

[0038] see in combination Figures 1 to 10 As shown, according to the embodiment of the present invention, the pump body assembly includes a suction port, an air supply port 1, a roller 2 and a cylinder 3, the cylinder 3 has a working chamber, and a valve hole 4 is also provided in the pump body assembly. One end is communicated with the working chamber, there is an air supply channel 5 between the air supply port 1 and the valve hole 4, and a valve core 6 is slidably arranged in the valve hole 4. The valve core 6 is used when the roller 2 separates the air supply port 1 and the suction port The air supply port 1 is communicated with the compression chamber of the working chamber, and / or the air supply passage 5 is closed when the pressure of the compression chamber of the working chamber is greater than the air supply pressure.

[0039] During the air supply process of the compressor, the air supply channel 5 can be opened or closed by the movement of the valve core 6 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com