Downhole track-free transport method

A technology of rail transportation and transport vehicles, which is applied in the field of transportation, can solve problems affecting production progress, etc., and achieve the effect of easy transportation and handling, convenient forward or backward, and large transportation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

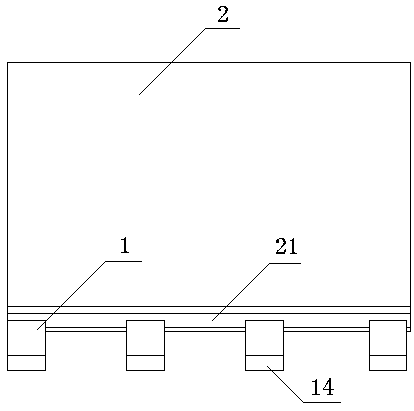

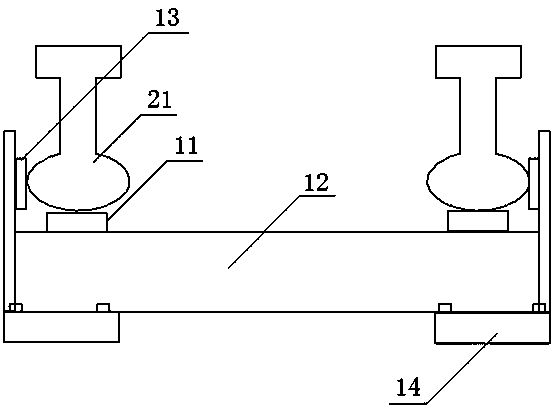

[0015] Such as figure 1 , 2 Shown, a kind of underground trackless transportation method, take roadway centerline as the base line of laying, lay vertically with several mutually independent slideway devices 1 and base line; The ground wheels 11 on both sides, the transport vehicle 2 is arranged on several sliding devices 1, and the bottom of the transport vehicle 2 contacts with the ground wheels 11. The I-shaped leg 21 is set, and the bottom surface of the I-shaped leg 21 is located on the ground wheel 11, so that Car slides on ground wheel 11, realizes advancing or retreating.

[0016] Described slideway device 1 comprises a crossbeam 12, and two cylindrical ground wheels 11 are respectively arranged at the two ends of crossbeam 12, and two limit wheels 13 are set respectively at both sides of crossbeam 12, and limit wheel 13 is positioned at the I-shaped leg 21 sides.

[0017] Pad blocks 14 are respectively arranged under both sides of the crossbeam 12, and the leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com