Intelligent large scattered material storage system for coping with strong wind and operating method

A storage system and large-scale technology, applied in the field of intelligent system and storage, can solve the problems of high construction cost, high later cost, poor ventilation and ventilation, and achieve the effect of low maintenance cost, low cost and convenient disassembly and assembly in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

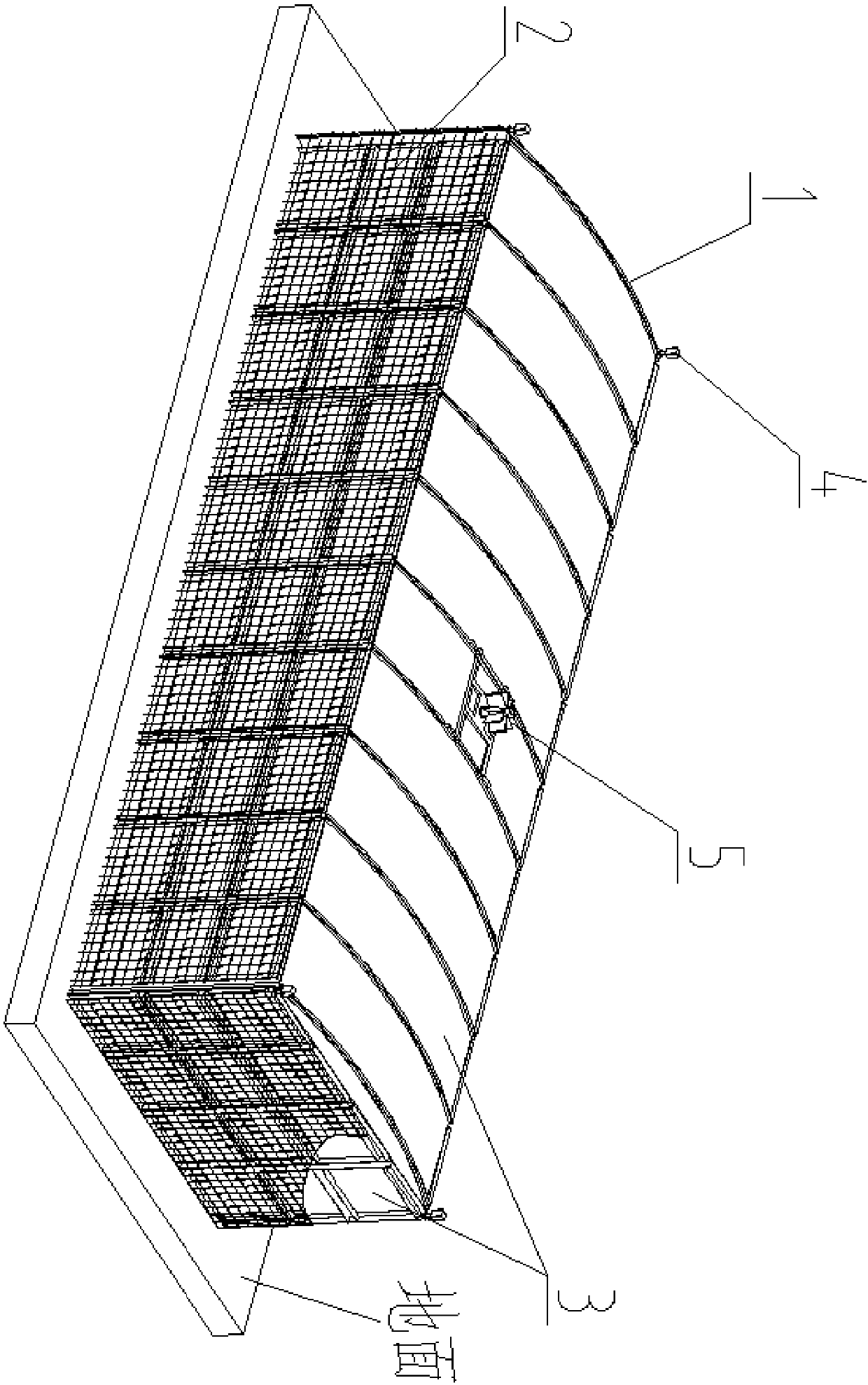

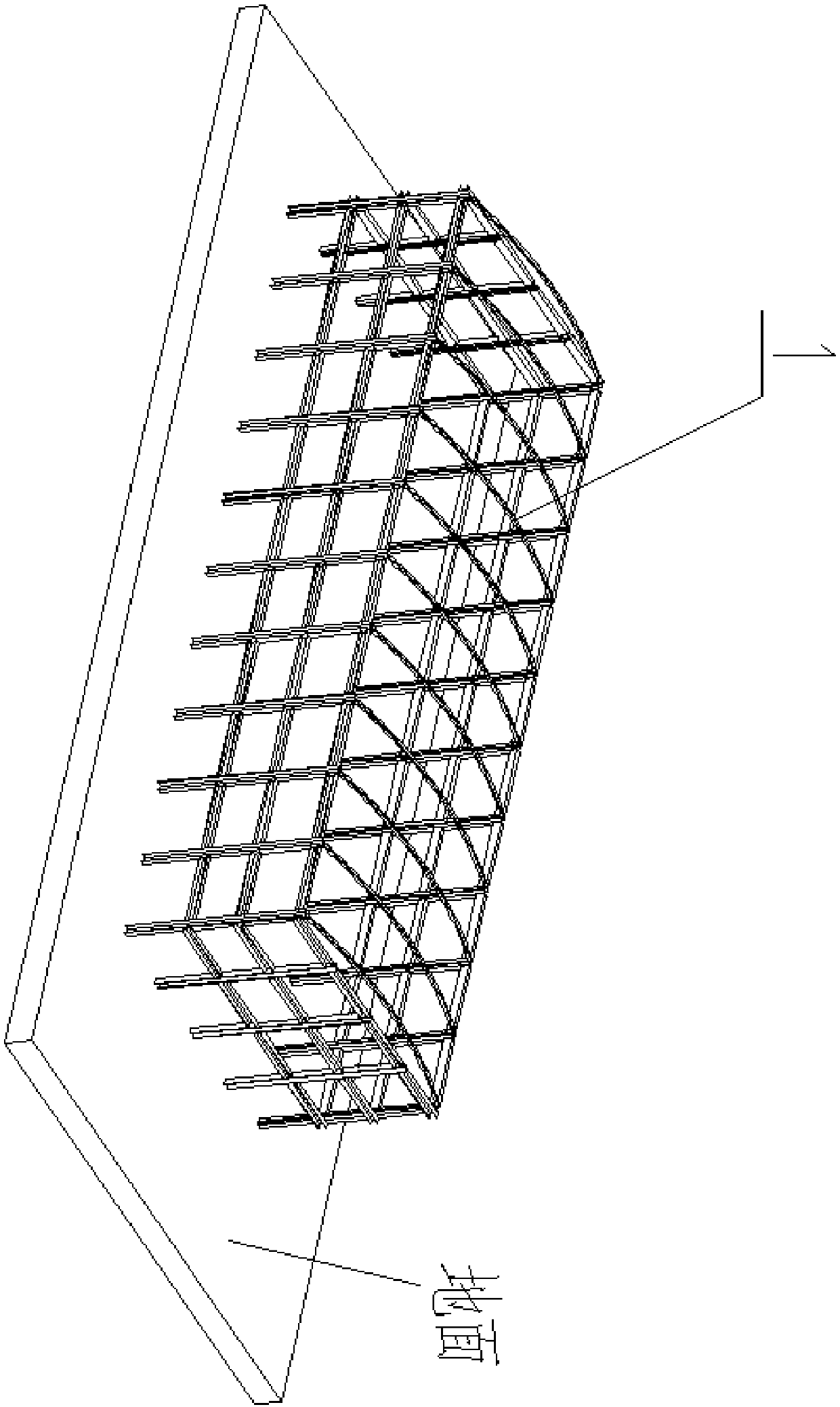

[0049] see Figure 1-9 , the present invention provides an intelligent large-scale bulk material storage system for strong winds, including a main steel structure frame 1, a large grid protection layer 2, a ventilation and dust suppression layer 3, an anemometer 4 and an active and passive protection system 5, It is characterized by:

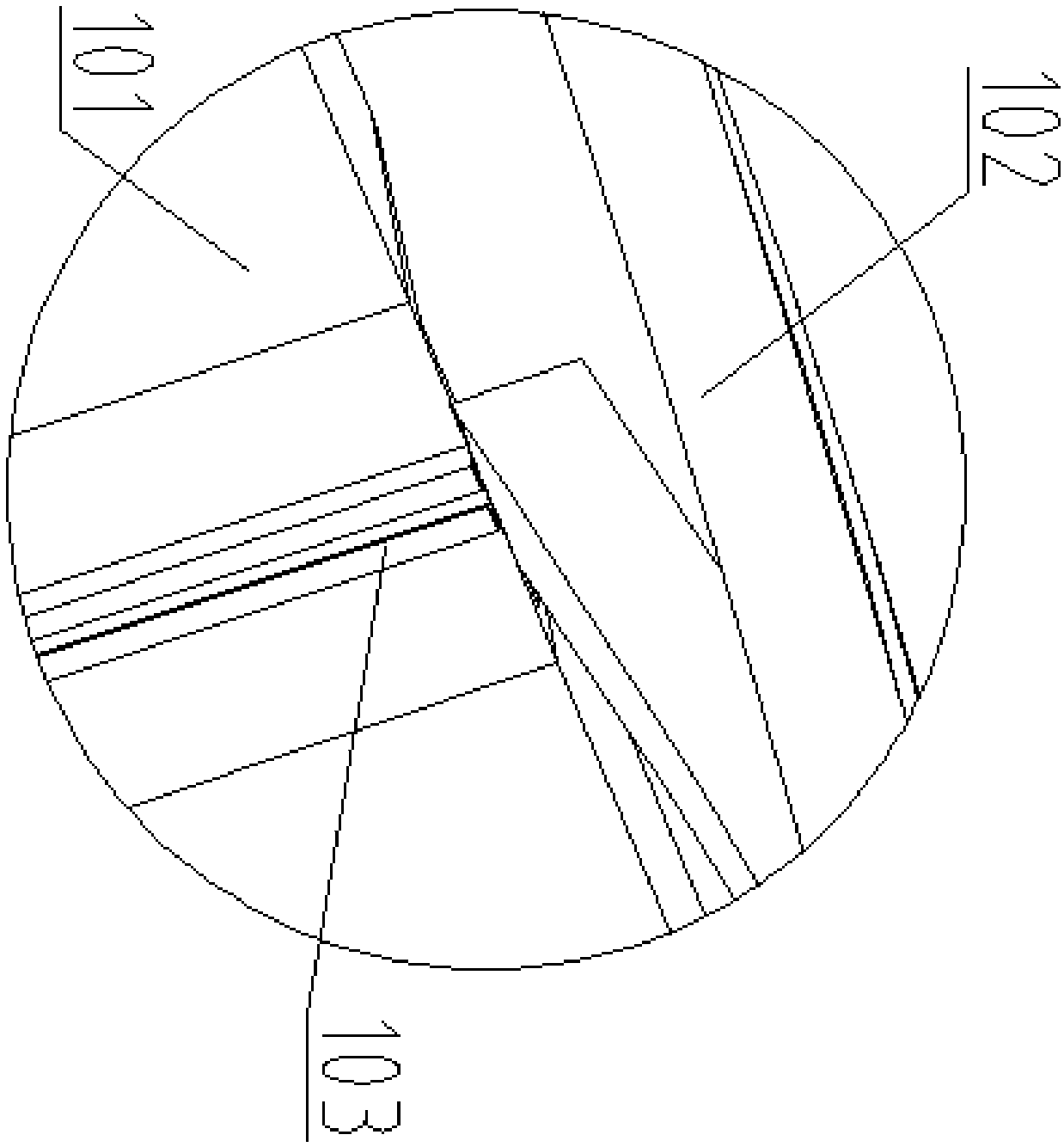

[0050] The main steel structure frame 1 includes a side profile structure frame 101 and a top surface structure frame 102. The side profile structure frame 101 is formed by connecting horizontally and vertically intersecting load-bearing beams, and each of the above-mentioned side profile structure frames 101 The inner side of each vertical load-bearing beam is provided with guide rails 103 of the same length, and the top surface structural frame 102 is made up of parallel or intersecting support beams, and is fixedly installed on the top of the side profile structural frame 101;

[0051] The large grid protective layer 2 is laid on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com