Stable and firm frame structure base plate and production process

A technology of frame structure and production process, which is applied in the direction of building structure, floor, building, etc., can solve the problems of unusable frame substrate, frame substrate cracking, and affecting production efficiency, so as to reduce the amount of repeated use, facilitate typesetting, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

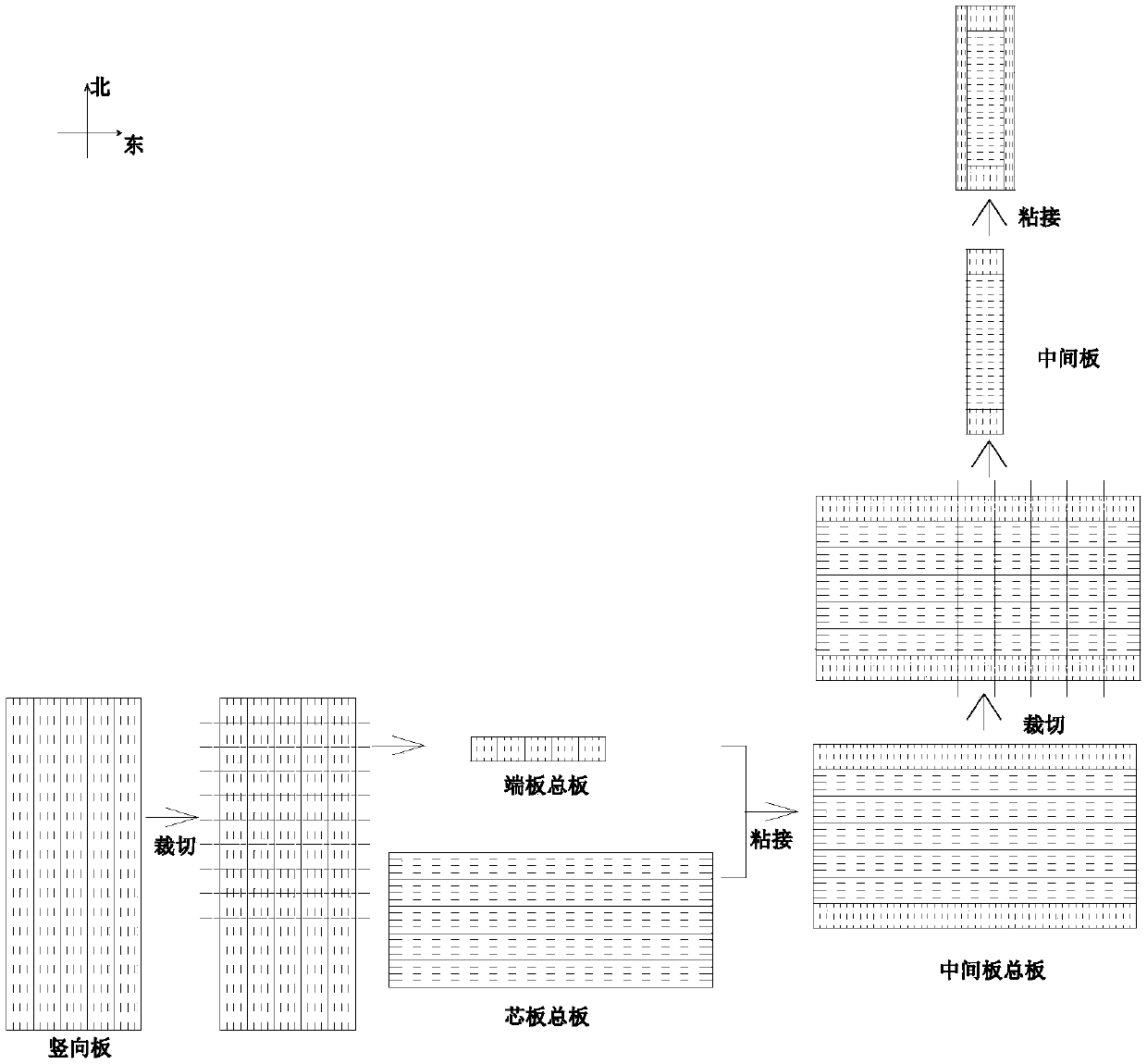

[0019] Example. A production process for a stable and firm frame structure substrate, consisting of figure 1 shown, including the following steps:

[0020] A. Make a vertical board with a vertical grain direction and a core board with a horizontal grain direction;

[0021] B. Cut the vertical plate horizontally to obtain a plurality of individual end plate main plates;

[0022] C. Adhere the end plate main plates at the two long sides of the core plate main plate respectively to obtain the middle plate main plate;

[0023] D. Vertically cut the main plate of the intermediate plate to obtain a plurality of independent intermediate plates;

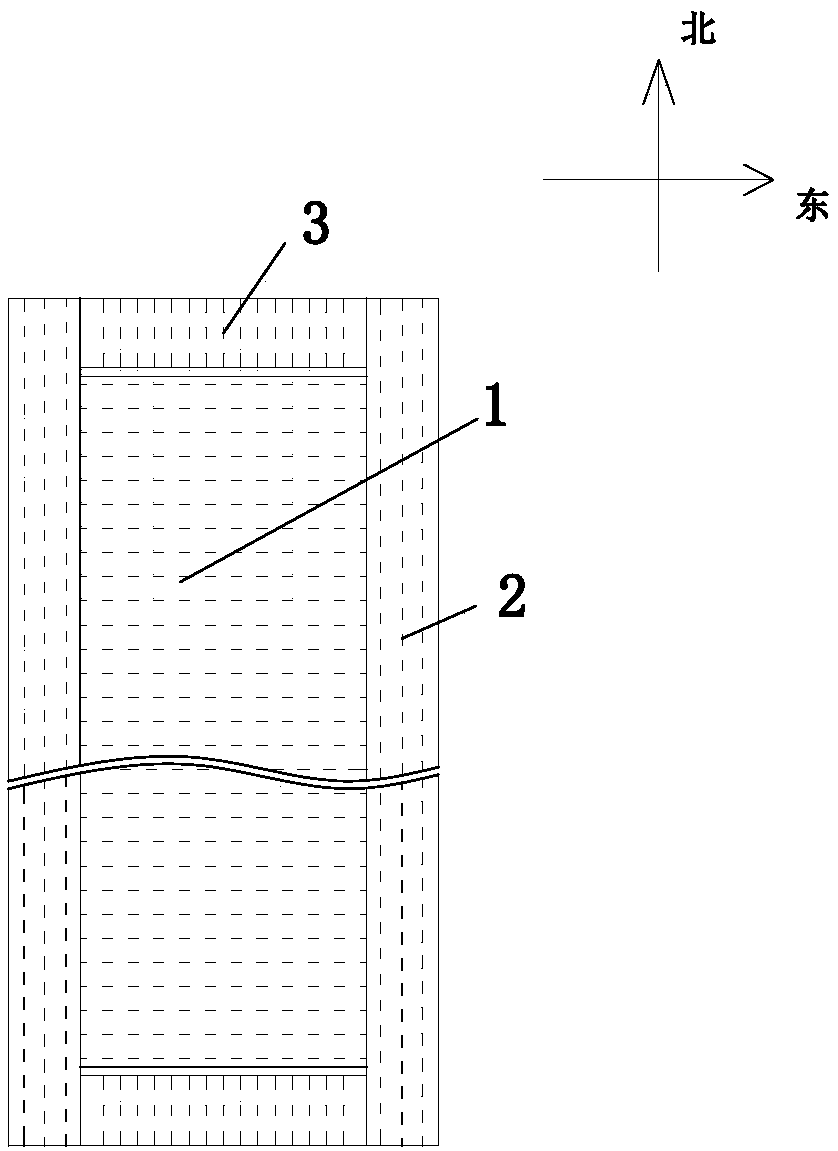

[0024] The intermediate plate includes a core plate and end plates located at the two short sides of the core plate;

[0025] E. Adhere the side boards whose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com