Low-temperature soaping enzyme, preparation method and application thereof, and low-temperature soaping process

A low-temperature soap and formula technology, which is applied in the field of low-temperature soaping enzyme preparation, low-temperature soaping enzyme, and low-temperature soaping technology, can solve the problems of poor color fixing effect and high energy consumption of soaping agents, achieves removal of dye floating color, reduces Soaping cost, effect of strong hard water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Low-temperature soaping enzymes include alkaline lipase 10%, N-vinylpyrrolidone vinylimidazole copolymer 10%, maleic acid acrylic acid copolymer 40%, sodium phenolsulfonate 30%, NNO 5%, sodium metasilicate 5% %. Mix 10% N-vinylpyrrolidone vinylimidazole copolymer, 40% maleic acid acrylic acid copolymer, 30% sodium phenolsulfonate, and 5% NNO in a conical powder mixer, then add 5% sodium metasilicate Continue to mix, finally add 10% alkaline lipase and mix evenly, finally make low-temperature soaping enzyme.

Embodiment 2

[0030]Low-temperature soaping enzymes include alkaline lipase 50%, N-vinylpyrrolidone vinyl acetate copolymer 25%, maleic acid styrene copolymer 10%, sodium methylphenol sulfonate 10%, NNO 2.5%, bicarbonate Sodium 2.5%. Mix 25% N-vinylpyrrolidone vinyl acetate copolymer, 10% maleic acid styrene copolymer, 10% sodium methylphenol sulfonate, and 2.5% NNO in a conical powder mixer, then add 2.5% carbonic acid Sodium hydrogen continues to mix, finally add 50% alkaline lipase and mix evenly, finally make low-temperature soaping enzyme.

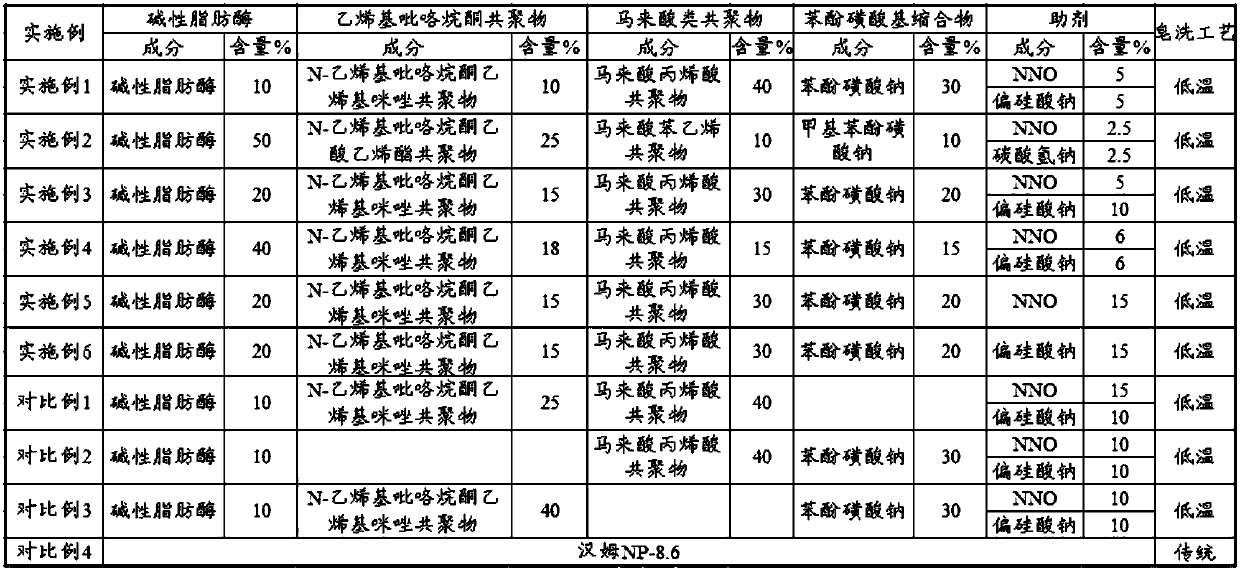

[0031] Examples 3 to 6 and comparative examples 1 to 3, except that the composition and content of each component are different, other steps are all the same as in Example 1 or 2. The composition and content of each component of Examples 3 to 6 and Comparative Examples 1 to 3 are specifically shown in Table 1.

[0032] For detecting the soaping effect of the low-temperature soaping enzyme provided by the invention, embodiment 1 to 6 and comparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com