Method for controlling nitrogen emission in process of preparing liquid oil from algae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The embodiment of the present invention describes a method for controlling nitrogen discharge in the process of preparing liquid oil from algae. The method specifically includes the following steps:

[0027] S1: After crushing spirulina and bamboo to particles smaller than 120 mesh, put them in an oven at 105°C for 24 hours to obtain pyrolysis raw materials;

[0028] S2: Use a fixed-bed reactor with a diameter of 45mm and a length of 60mm for pyrolysis. After heating the reactor to a specified temperature of 600°C, quickly send 2g of bamboo into the middle of the reactor for a reaction time of 30min, so that the biomass is fully Decompose, feed 200mL / min Ar as an inert carrier gas to obtain biomass carbon additives;

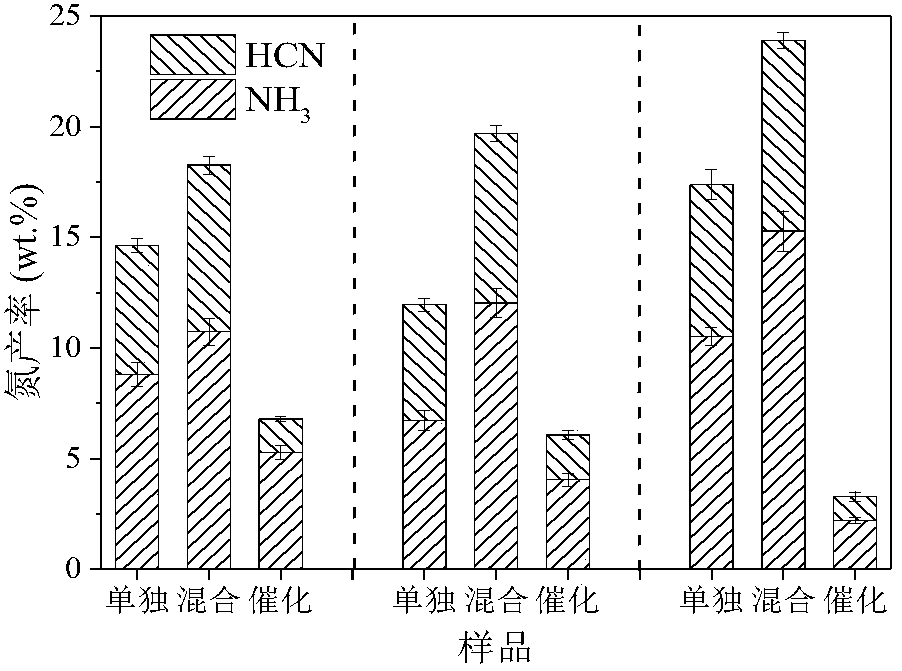

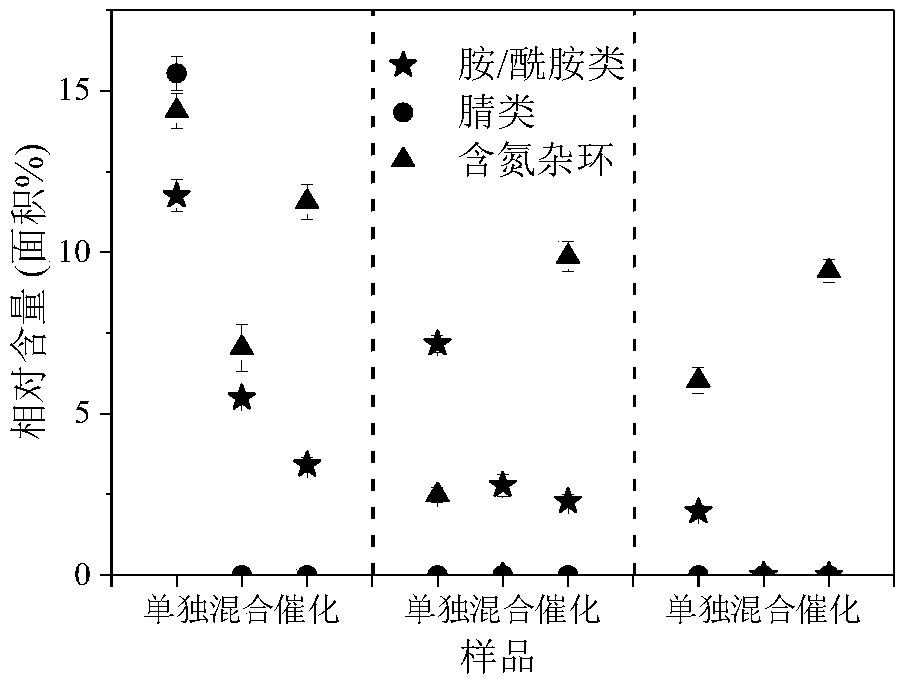

[0029] S3: Mix spirulina and bamboo at a mass ratio of 1:1 to form a mixture, put it in an oven at 105°C for 24 hours, then carry out a mixed pyrolysis reaction at 600°C for 30 minutes, and pyrolyze the volatile matter at the same time The nitrogen-contai...

Embodiment 2

[0033] The steps of this example are the same as those of Example 1, except that the algae biomass is Nannochloropsis.

Embodiment 3

[0035] The steps of this embodiment are the same as in Example 1, except that the algae biomass is Enteromorpha.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com