Chitosan-graphene oxide sponge, preparing method and application

A graphene sponge and chitosan technology, which is applied in the direction of biochemical fuel cells and the like, can solve the problems of disintegration and rupture of the chitosan system, and achieve the effects of simple preparation method, easy adhesion and growth, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

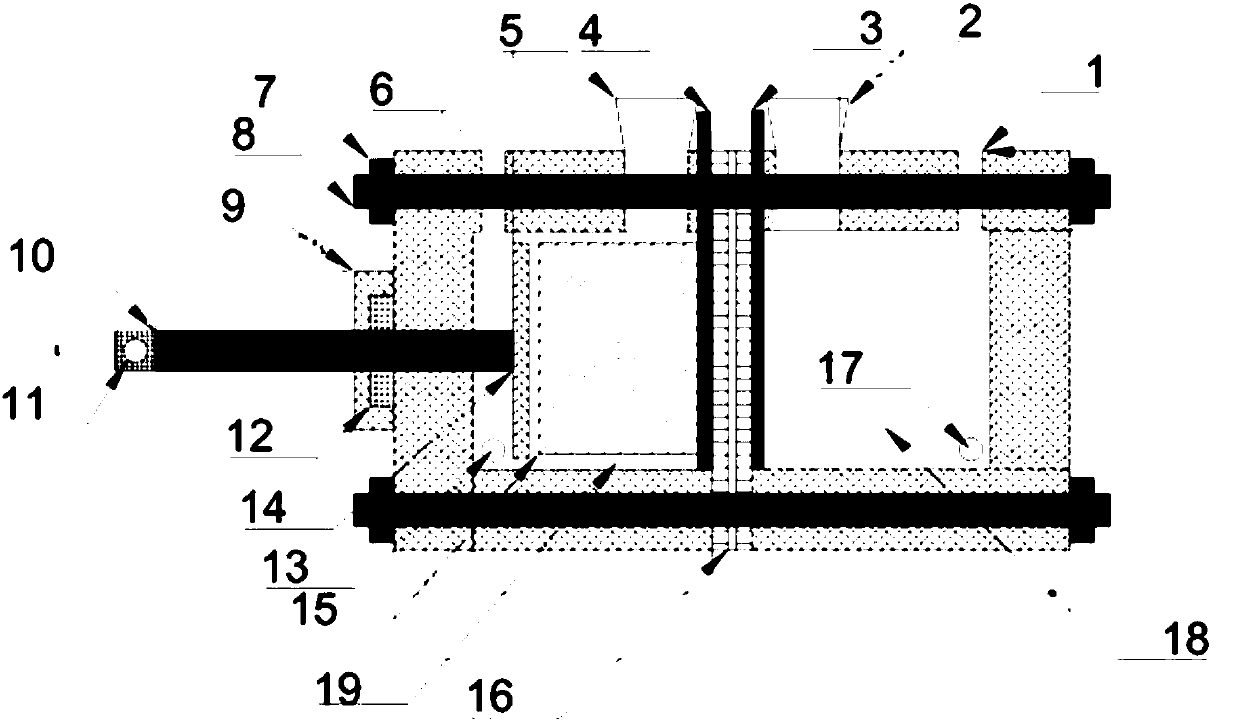

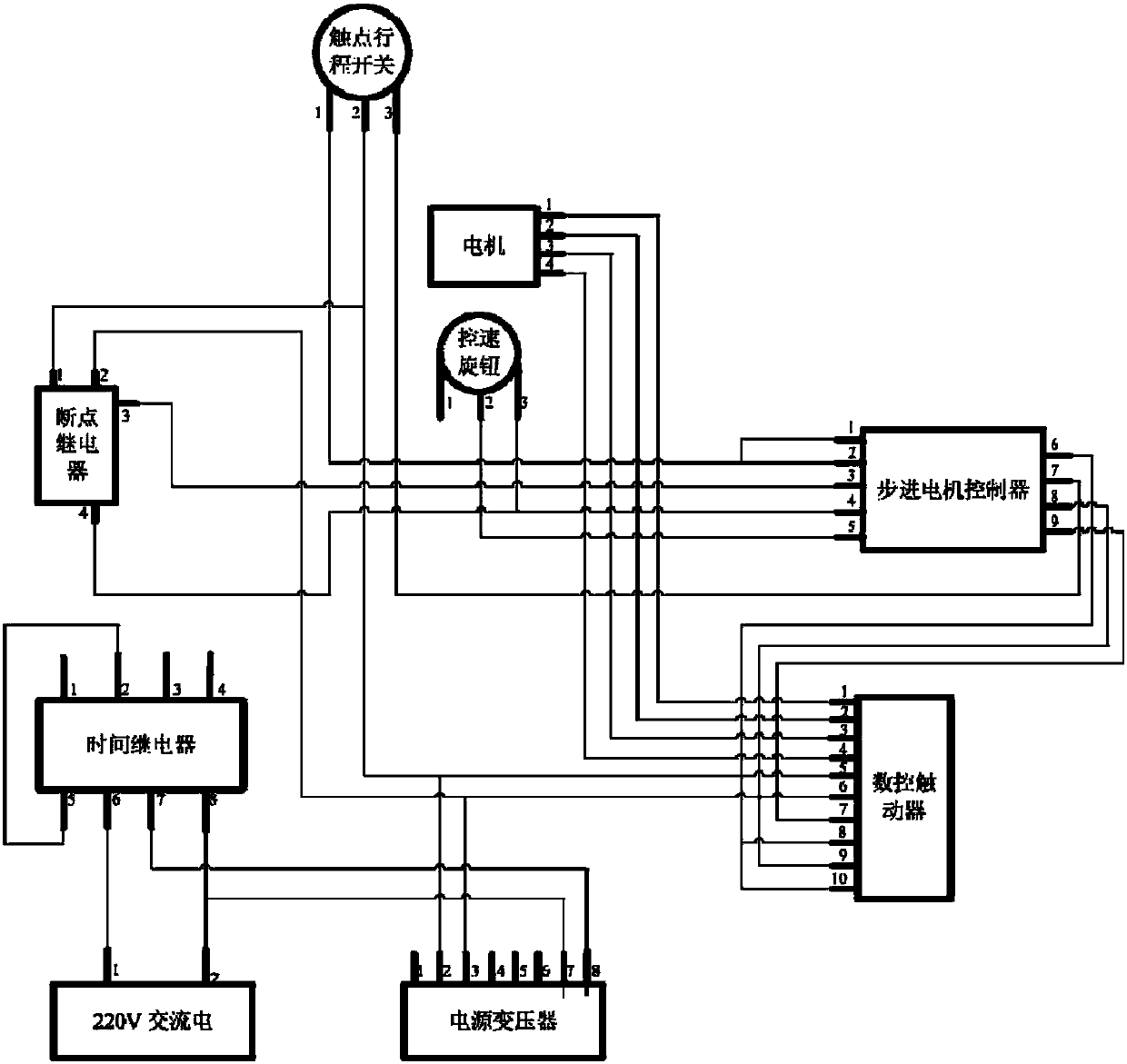

Method used

Image

Examples

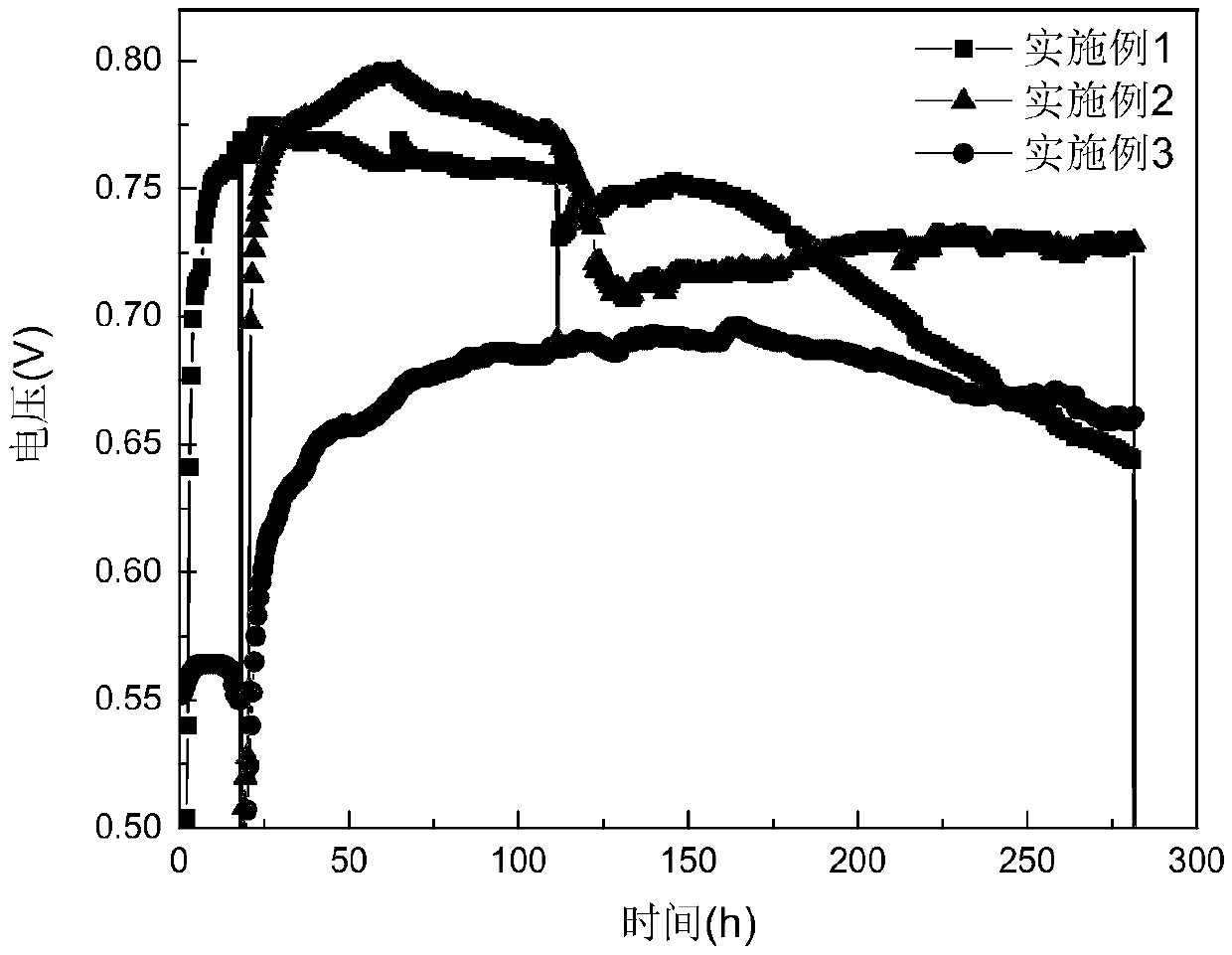

Embodiment 1

[0039] (1) Get a certain quality of graphite oxide, prepare the graphite oxide suspension of 4mg / mL;

[0040] (2) Place the suspension in step (1) in an ultrasonic cleaning machine for ultrasonic cleaning for 60 minutes to make it evenly dispersed to obtain a graphene oxide solution;

[0041] (3) Take 100 mL of the solution prepared in step (2), add 3 mL of glacial acetic acid drop by drop under the condition of magnetic stirring, and mix well;

[0042] (4) Add 0.1mol / L FeCl dropwise to the solution in step (3) under the condition of magnetic stirring 2 Solution 5mL, and mix well;

[0043] (5) Add 4mL of 1mol / L sodium benzenesulfinate solution dropwise to the solution in step (4) under the condition of magnetic stirring, and mix well;

[0044] (6) slowly add the chitosan of 2g in the solution in step (5) under the situation of magnetic stirring (or mechanical stirring), and mix homogeneously;

[0045] (7) vacuumizing the solution in step (6), removing the bubbles in the sol...

Embodiment 2

[0051] (1) Get a certain quality of graphite oxide, prepare the graphite oxide suspension of 4mg / mL;

[0052] (2) placing the suspension in step (1) in an ultrasonic cleaning machine for ultrasonic cleaning for 60 min to disperse it evenly to obtain a graphene oxide solution;

[0053](3) Take 100 mL of the solution in step (2), add 3 mL of glacial acetic acid drop by drop under the condition of magnetic stirring, and mix well;

[0054] (4) Add 0.1mol / L FeCl dropwise to the solution in step (3) under the condition of magnetic stirring 2 Solution 25mL, and mix well;

[0055] (5) Add 4 mL of 1 mol / L sodium benzenesulfinate solution dropwise to the solution in step (4) under the condition of magnetic stirring, and mix well;

[0056] (6) slowly add the chitosan of 4g in the solution in step (5) under the situation of magnetic stirring (or mechanical stirring), and mix homogeneously;

[0057] (7) vacuumizing the solution in step (6), removing the bubbles in the solution to obtain...

Embodiment 3

[0063] (1) Get a certain quality of graphite oxide, prepare the graphite oxide suspension of 4mg / mL;

[0064] (2) placing the suspension in step (1) in an ultrasonic cleaning machine for ultrasonic cleaning for 60 min to disperse it evenly to obtain a graphene oxide solution;

[0065] (3) Take 100 mL of the solution in step (2), add 3 mL of glacial acetic acid drop by drop under the condition of magnetic stirring, and mix well;

[0066] (4) Add 0.1mol / L FeCl dropwise to the solution in step (3) under the condition of magnetic stirring 2 Solution 50mL, and mix well;

[0067] (5) Add 4mL of 1mol / L sodium benzenesulfinate solution dropwise to the solution in step (4) under the condition of magnetic stirring, and mix well;

[0068] (6) slowly add the chitosan of 2g in the solution in step (5) under the situation of magnetic stirring (or mechanical stirring), and mix homogeneously;

[0069] (7) vacuumizing the solution in step (6), removing the bubbles in the solution to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com