Direct-drive type manual half-basin lifting device for automobile seat

A car seat and lifting device technology, which is applied to vehicle seats, movable seats, special positions of vehicles, etc., can solve problems such as poor stability, and achieve the effects of overcoming poor stability, improving operating comfort, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

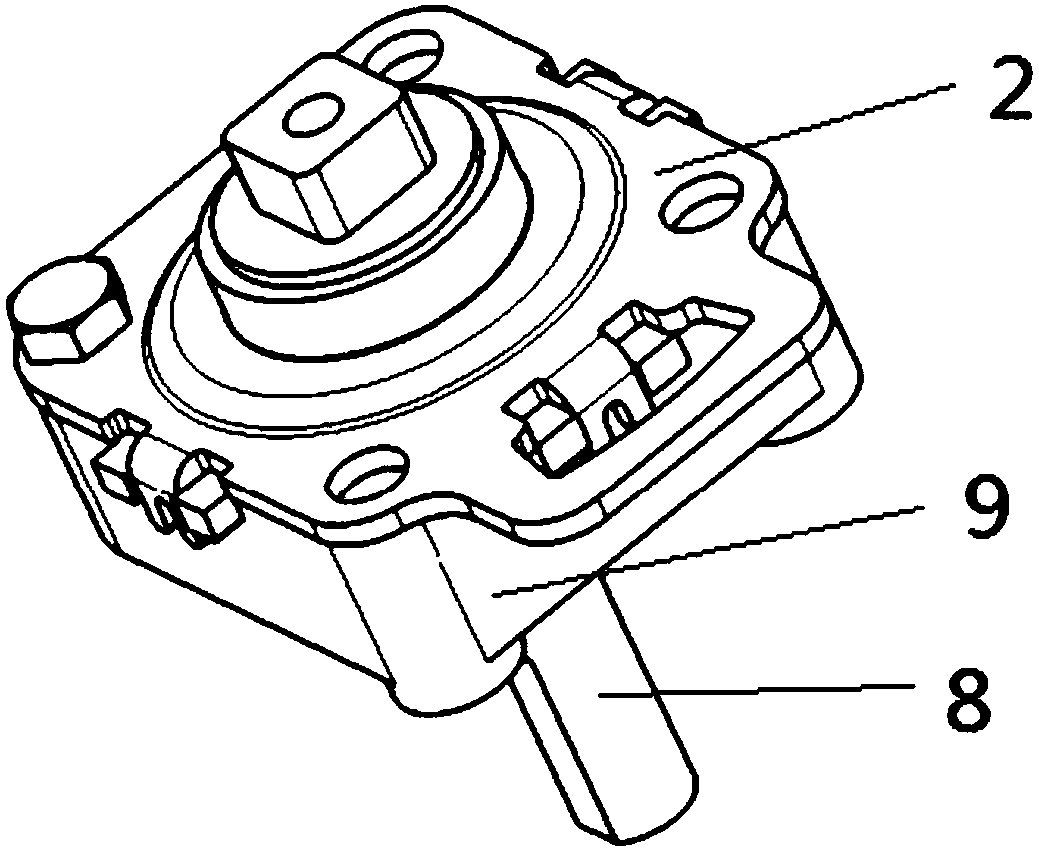

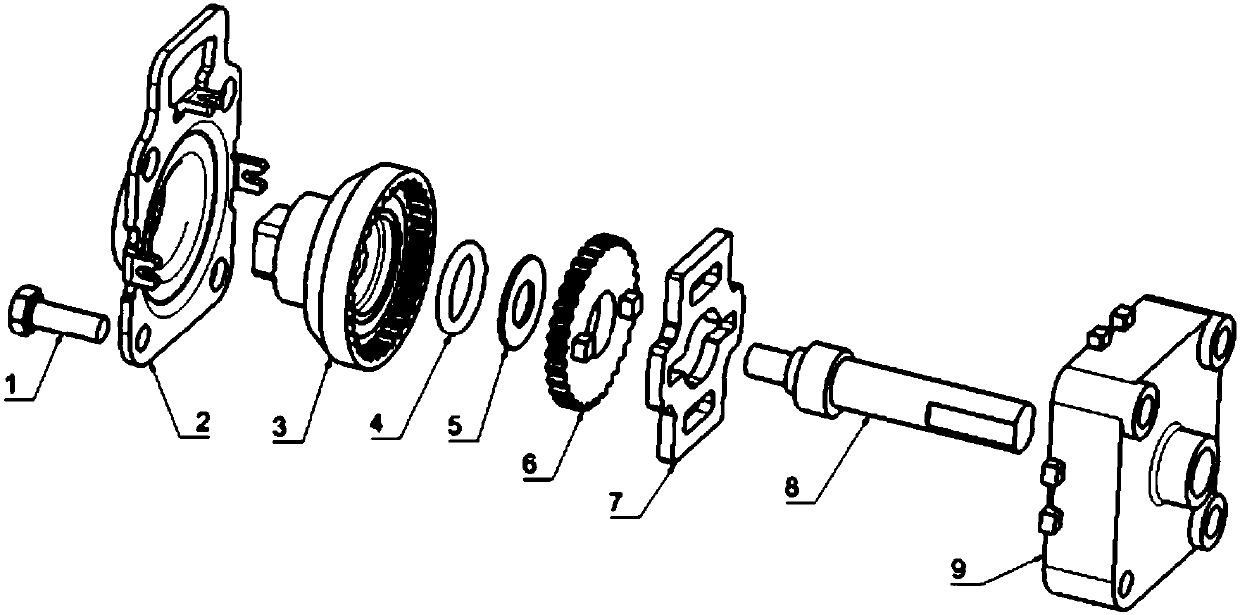

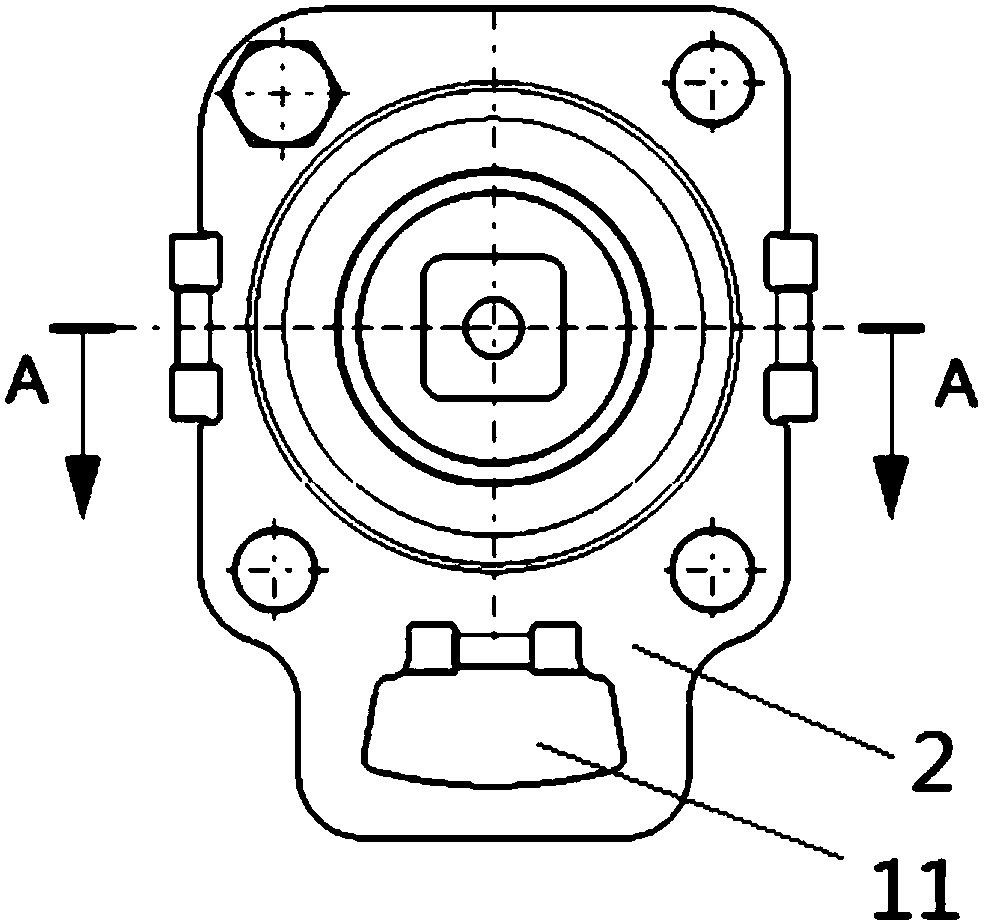

[0019] As shown in the figure: a direct-drive manual semi-pot lifting device for a car seat, including a case cover 2, a ring gear 3, a gear 6, a slider 7, an eccentric shaft 8 and a case body 9. Wherein, the box cover 2 is tightly connected with the box body 9 by using the bolt 1 and three pressure riveting. The input end of the eccentric shaft 8 is inserted into the central hole of the box body 9, the output end of the eccentric shaft 8 is installed with the ring gear 3, and the output end of the ring gear 3 passes through the case cover 2 and is welded with the half basin connecting rod. A chute is provided on the box body 9, and the slide block 7 is sleeved on the eccentric shaft 8 and placed in the chute, and the slide block 7 can slide in the chute. The gear 6 is set on the eccentric wheel of the eccentric shaft 8, and the gear 6 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com