Preparation method for conductive sensing textile based on graphene

A graphene and fabric technology, applied in the direction of chemical instruments and methods, cellulose plastic material layered products, layered products, etc., can solve the problems of not being easy to use multiple times, single sensor sensing elements, etc., and achieve low production cost, Wide application prospects and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

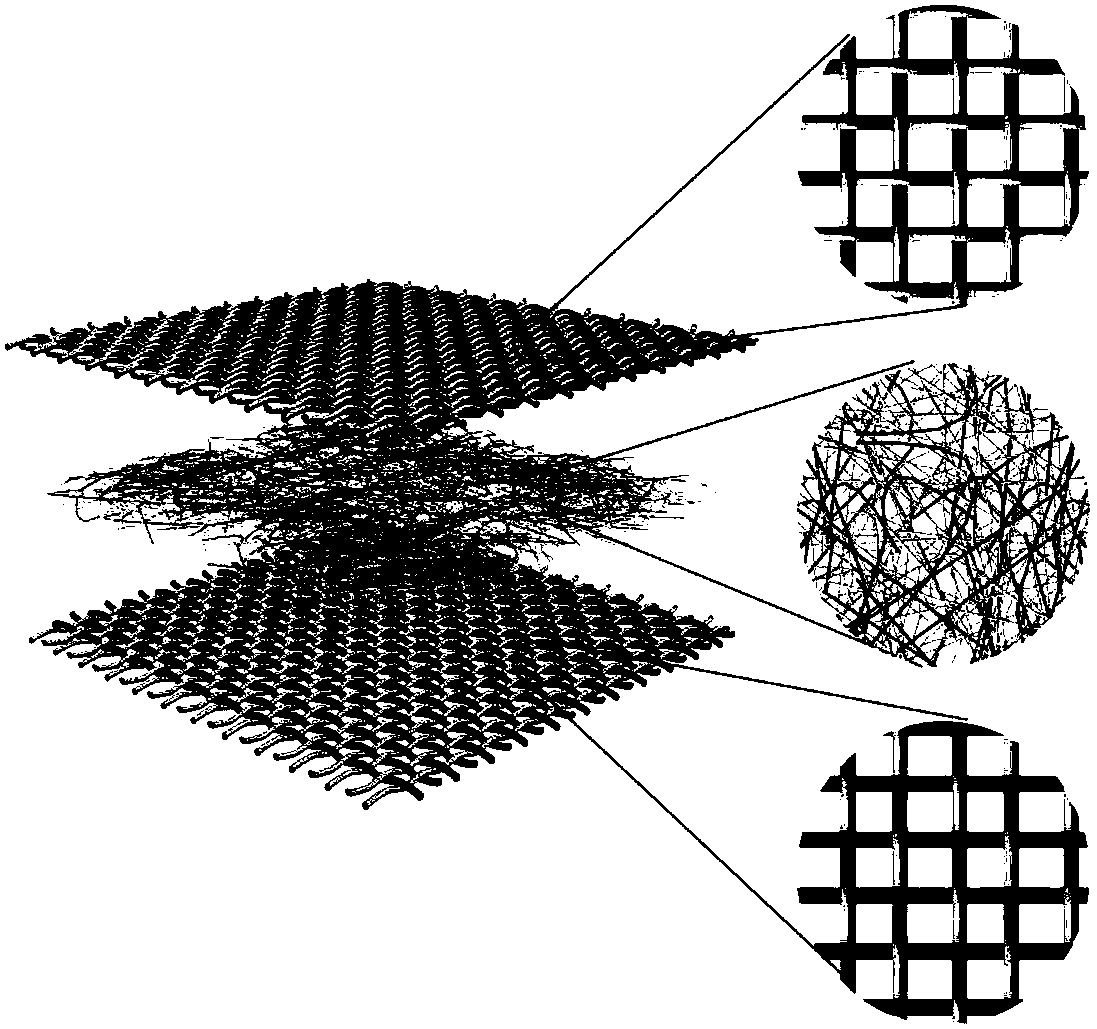

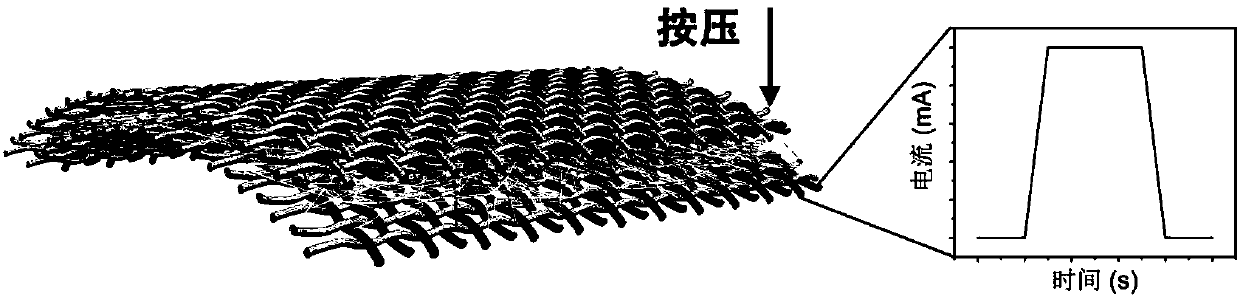

[0028] Such as figure 1 with figure 2 As shown, 55D acrylic filaments are soaked in graphene conductive paste to prepare graphene conductive filaments, and the conductive properties of conductive filaments are improved by reducing the particle size of graphene, so that the specific resistance is less than 100Ω·cm; the conductive filaments Interwoven with other ordinary chemical fibers to form a fabric, the gap between the conductive fibers is about 0.2mm to form a base; also use a similar method to prepare 3D graphene conductive acrylic staple fibers, the specific resistance is less than 100Ω cm, and the conductive staple fibers are mixed with spandex To form a non-woven fabric, the proportion of conductive short fibers is 20%, and the thickness of the non-woven fabric is 2mm; the uppermost layer is a polyester cloth, forming a sandwich structure.

[0029] Under the action of external force, the resistance change value of the conductive fabric is in the range of 5kΩ-100kΩ, a...

Embodiment 2

[0031] Such as figure 1 with figure 2 As shown, the 55D nylon filament is soaked in the graphene conductive paste to prepare the graphene conductive filament, and the conductive performance of the conductive filament is improved by reducing the particle size of the graphene, so that the specific resistance is less than 50Ω·cm; the conductive filament Interwoven with other common chemical fibers to form a fabric, the gap between conductive fibers is about 0.2mm to form a base; also use a similar method to prepare 3D graphene conductive nylon staple fibers, the specific resistance is less than 80Ω cm, and the conductive staple fibers and spandex mixed weave To form a non-woven fabric, the proportion of conductive short fibers is 40%, and the thickness of the non-woven fabric is 1mm; the uppermost layer is polyester cloth, forming a sandwich structure.

[0032] Under the action of external force, the resistance change value of the conductive fabric is in the range of 2kΩ-20kΩ, ...

Embodiment 3

[0034] Such as figure 1 with figure 2 As shown, 20D polypropylene filaments are soaked in graphene conductive paste to prepare graphene conductive filaments. By reducing the particle size of graphene, the conductivity of conductive filaments is improved, so that the specific resistance is less than 300Ω·cm; the conductive filaments Interweave with other ordinary chemical fibers to form a fabric, and the gap between conductive fibers is about 0.1mm to form a base; also use a similar method to prepare 3D graphene conductive polypropylene staple fibers, the specific resistance is less than 500Ω·cm, and mix conductive staple fibers with spandex To form a non-woven fabric, the proportion of conductive short fibers is 20%, and the thickness of the non-woven fabric is 1mm; the uppermost layer is polyester cloth, forming a sandwich structure.

[0035] Under the action of external force, the resistance change value of the conductive fabric is in the range of 10kΩ-500kΩ, and the resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com