Car film pasting jig

A car film and fixture technology, applied to home appliances, other home appliances, household components, etc., can solve problems such as interference with the driver's line of sight, inconvenience, and hidden dangers of driving safety, so as to protect personal safety, protect glasses, and reduce driving safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

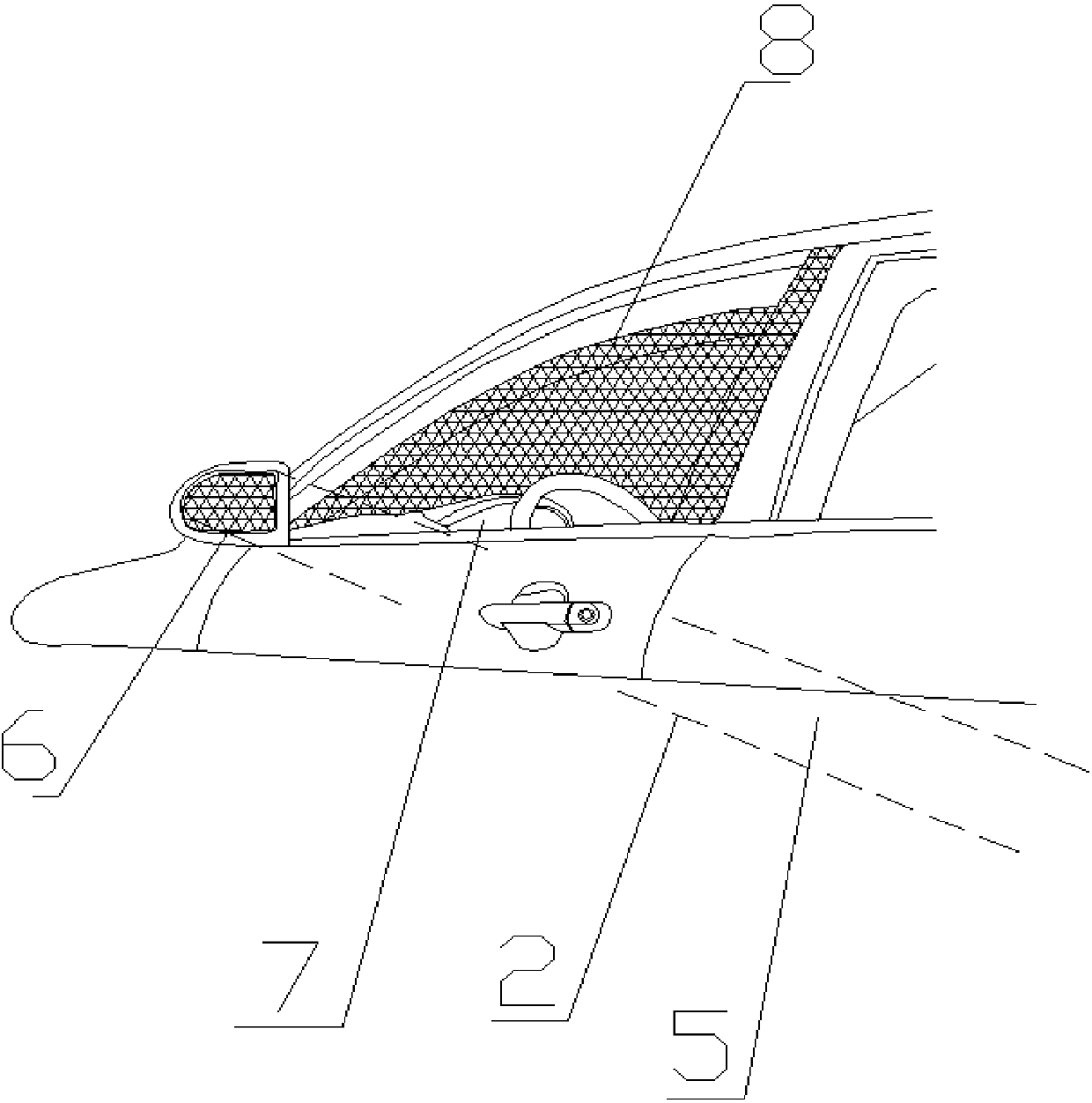

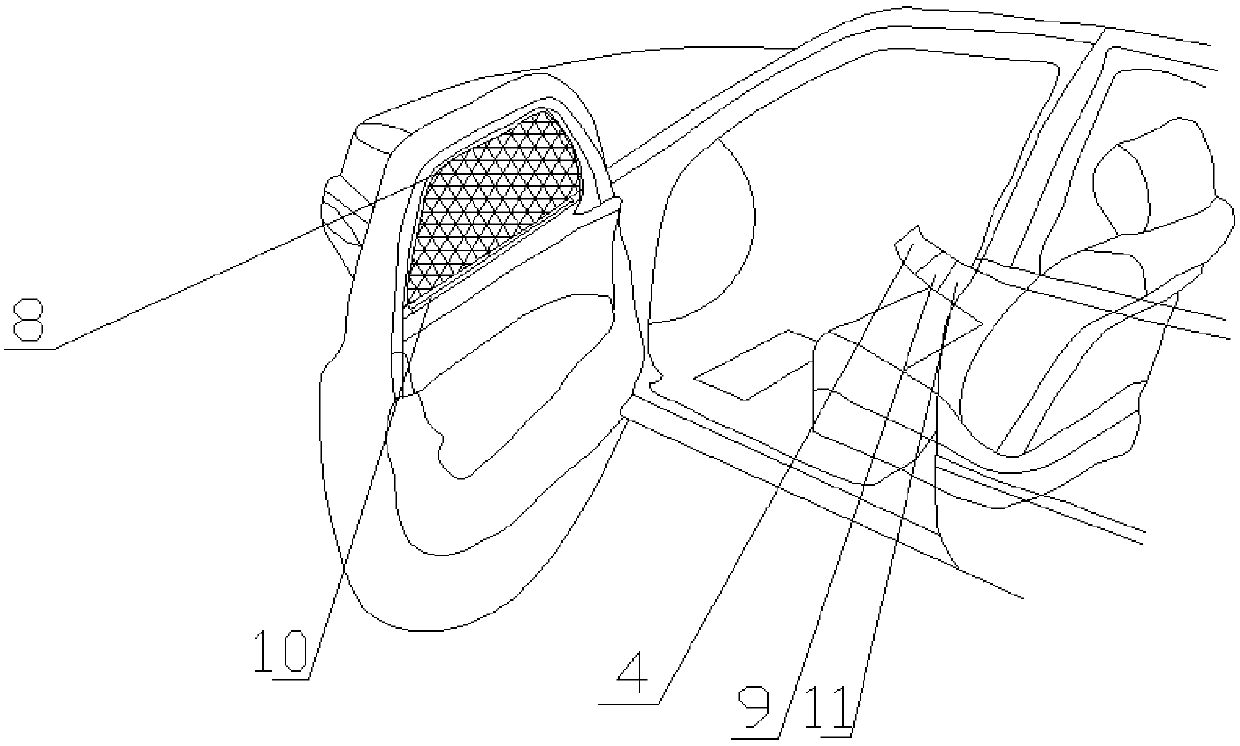

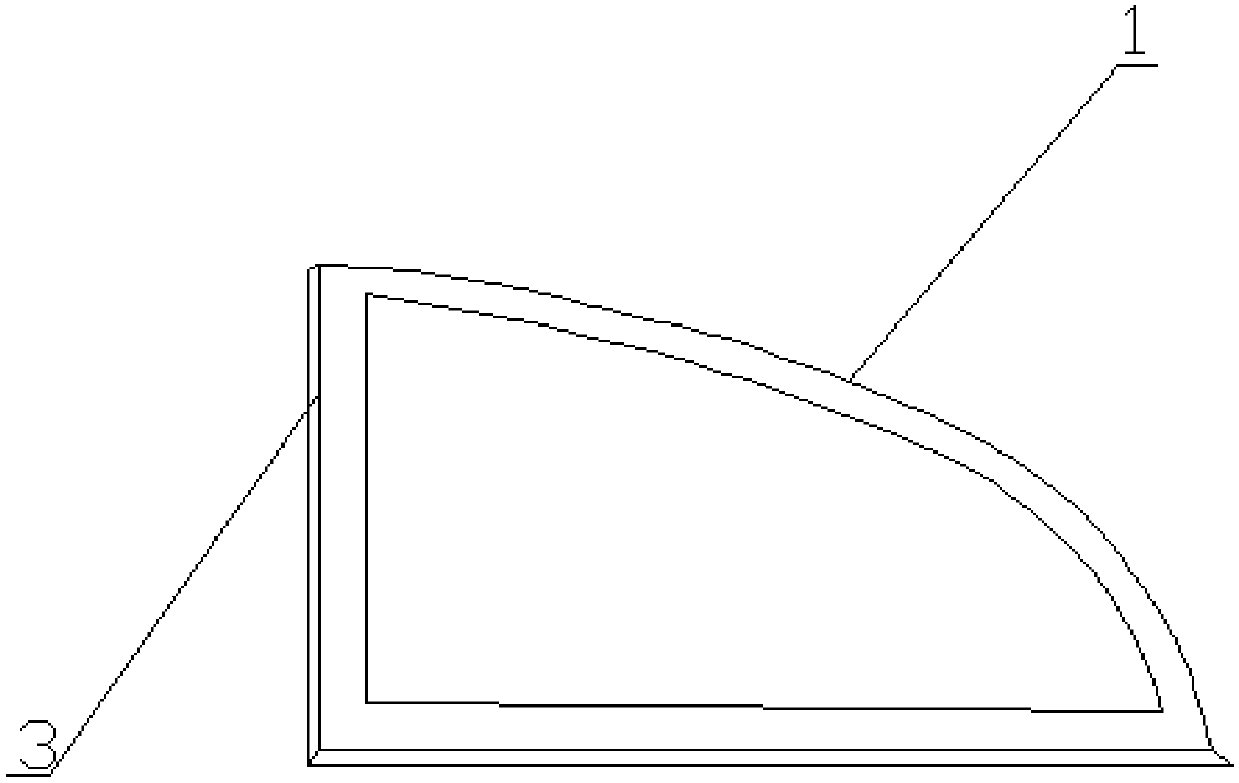

[0040] Using the present invention, the car side window glass 8 is pasted with a film, and the driver adjusts the angle of the car rearview mirror 6 in an electric or manual manner. When the angle of the car rearview mirror 6 changes, the area of the reflected light source is different thereupon. , means that the shape and position of the film on the side window glass 8 of the car are different, and the film frame fixture 1 needs to control the shape and position of the film. Reflected on the side window glass 8 of the car, different position areas or shapes are formed, and the user cuts and sticks the film according to the formed area shape.

[0041] The simulated light source 4 in the car includes a simulated light source driving base 11, the simulated light source driving base 11 can be stretched and adjusted in position, and the simulated light source driving device 9 drives the simulated light source 4 in the car to shine on the car rearview mirror 6 through the adjustme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com