Machining equipment for automobile part mold

A technology for mold processing and auto parts, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of long time and low efficiency of cleaning, avoid low cleaning efficiency, increase the scope of cleaning, and improve the linkage. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further detailed description through specific implementations:

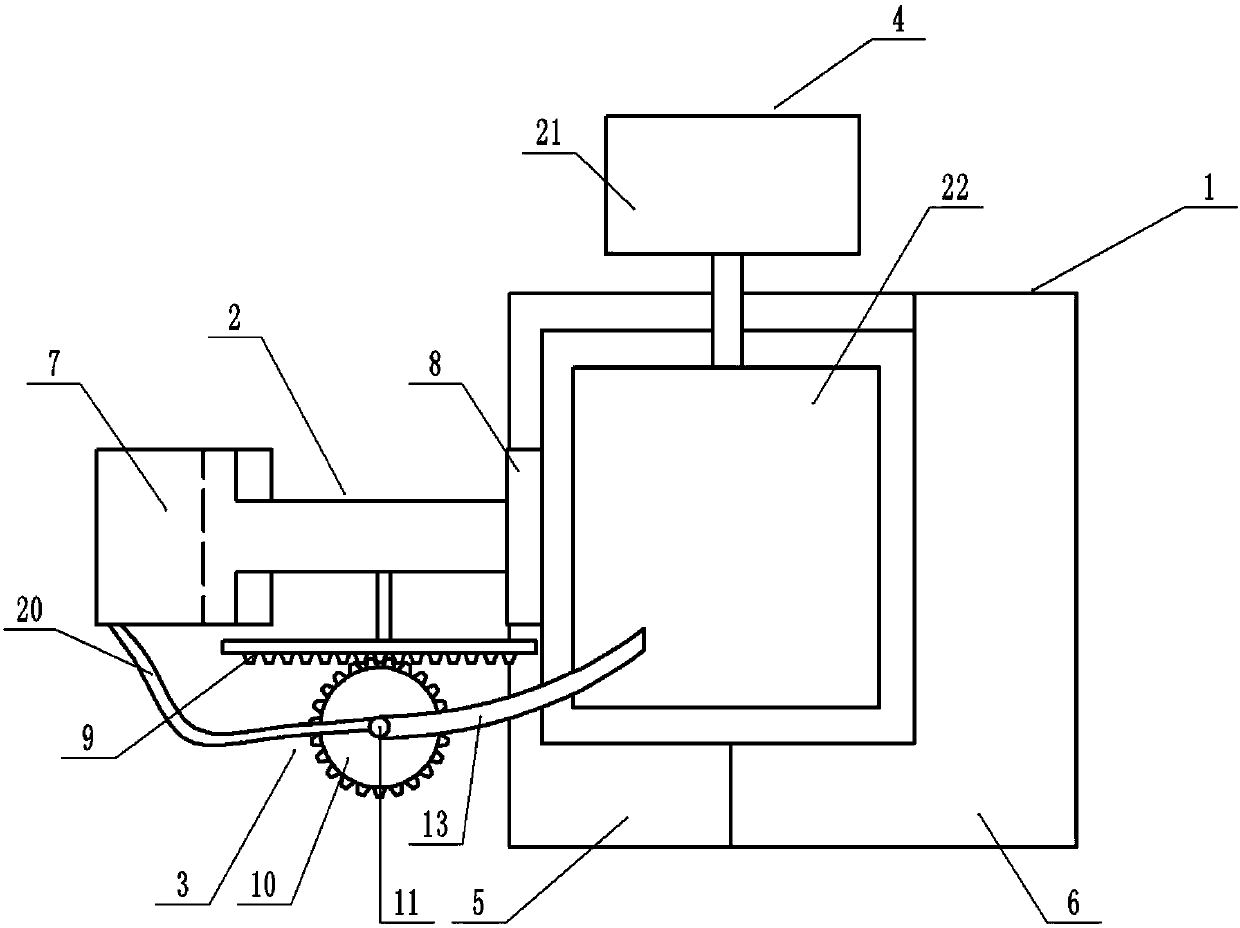

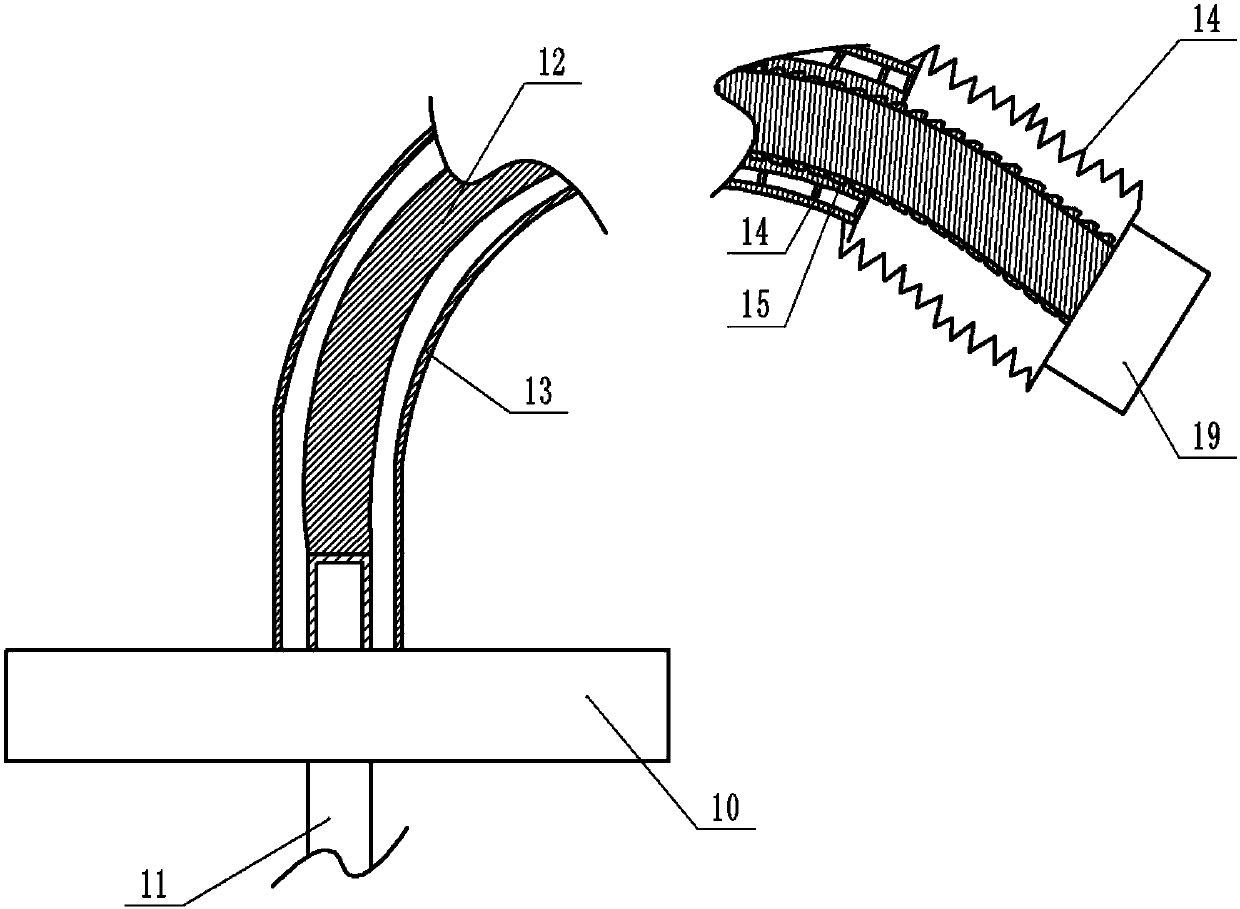

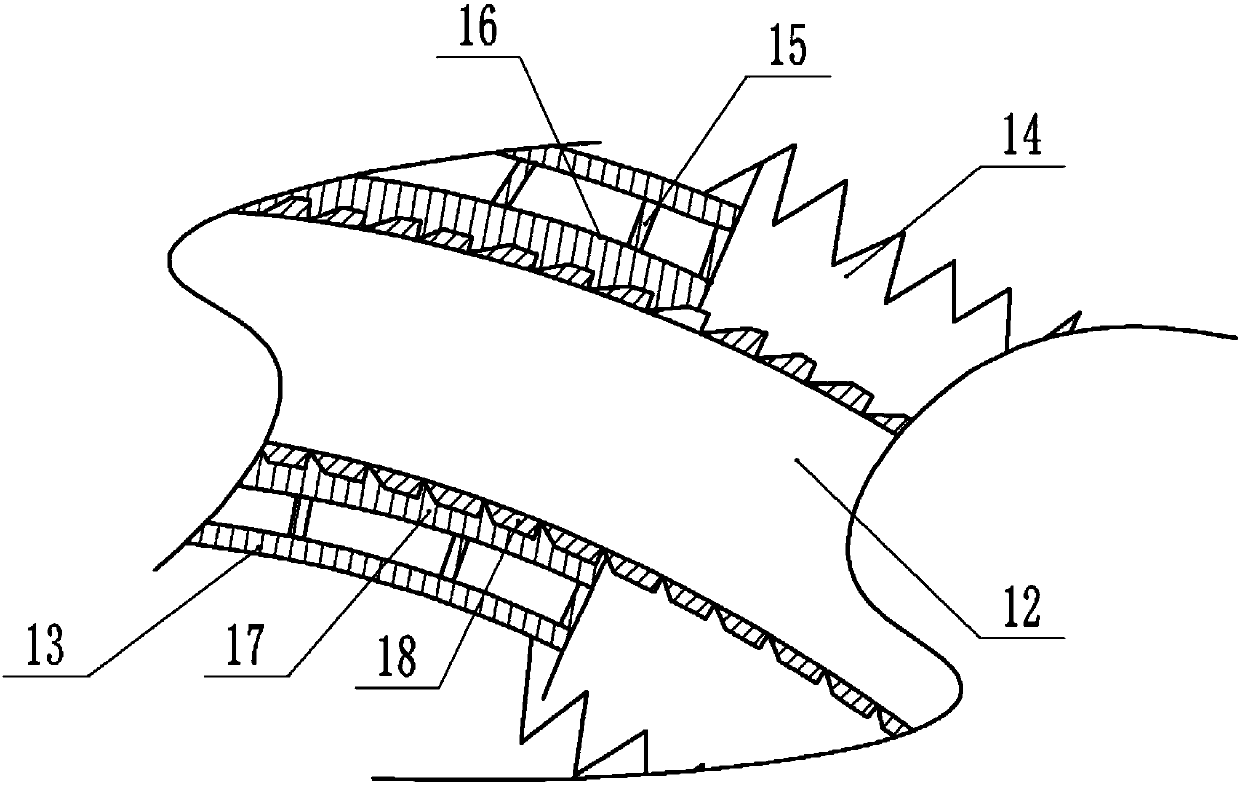

[0022] The reference signs in the drawings of the specification include: mold processing fixing seat 1, mold clamping device 2, mold cleaning device 3, mold grinding device 4, processing base 5, side stopper 6, first cylinder 7, clamping block 8. Rack 9, gear 10, wheel shaft 11, flexible shaft 12, bushing 13, telescopic section 14, support column 15, inner sleeve 16, internal thread 17, external thread 18, nozzle 19, air duct 20, section Two cylinders 21, grinding block 22.

[0023] The embodiments of auto parts mold processing equipment are basically as attached figure 1 Shown: Including the frame, the mold processing fixing seat 1, the mold clamping device 2 arranged on the side of the mold processing fixing seat 1, the mold cleaning device 3 and the mold grinding device 4 arranged adjacent to the mold clamping device 2, the mold The processing base 1 includes a processing base 5 and a sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com