Multifunctional stirring device for aluminum alloy production

A stirring equipment and aluminum alloy technology, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve the problems of inconvenient disassembly, affecting work efficiency, and single function, so as to facilitate installation and disassembly, improve The effect of maintaining efficiency and ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

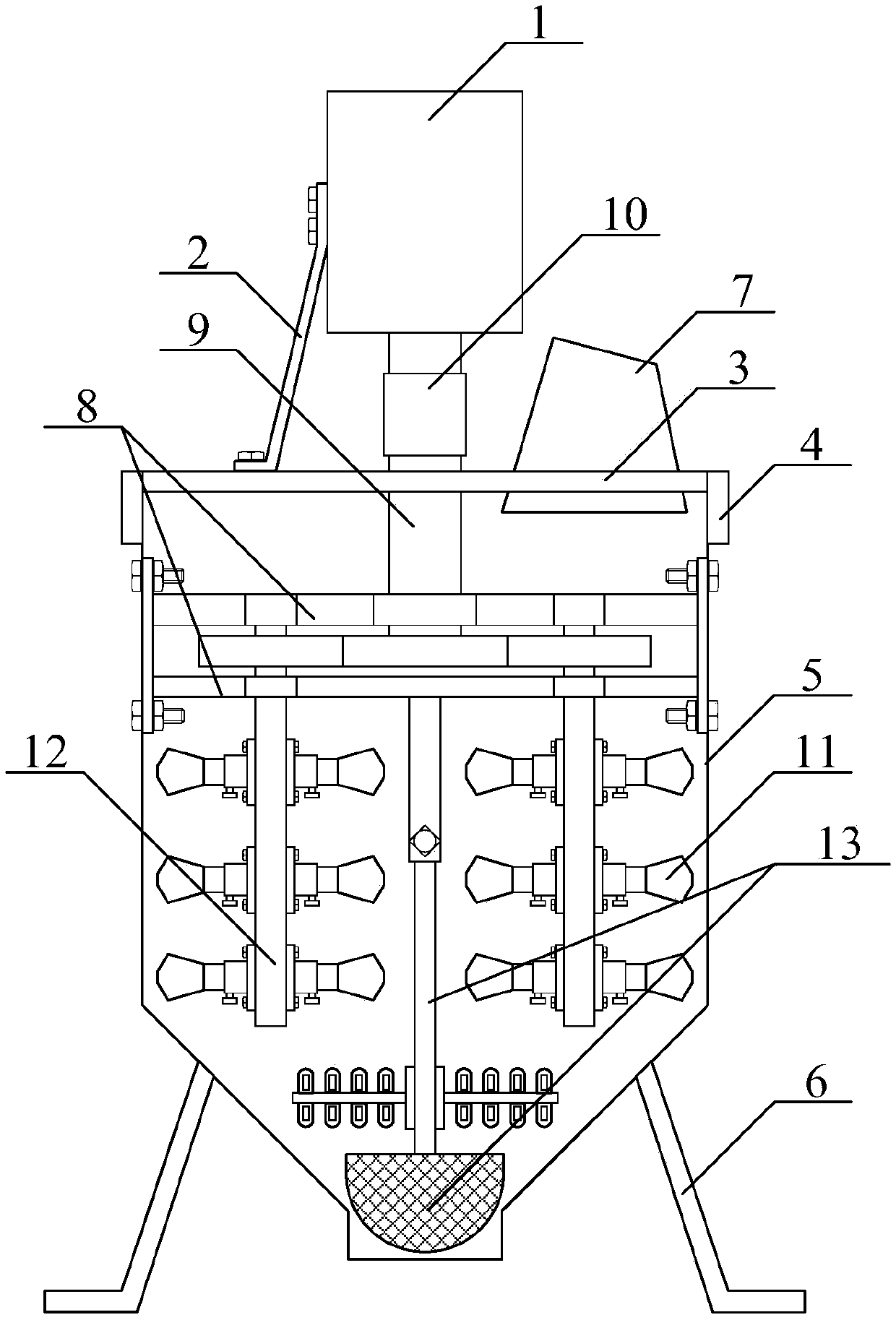

[0034] as attached figure 1 to attach Figure 4 shown

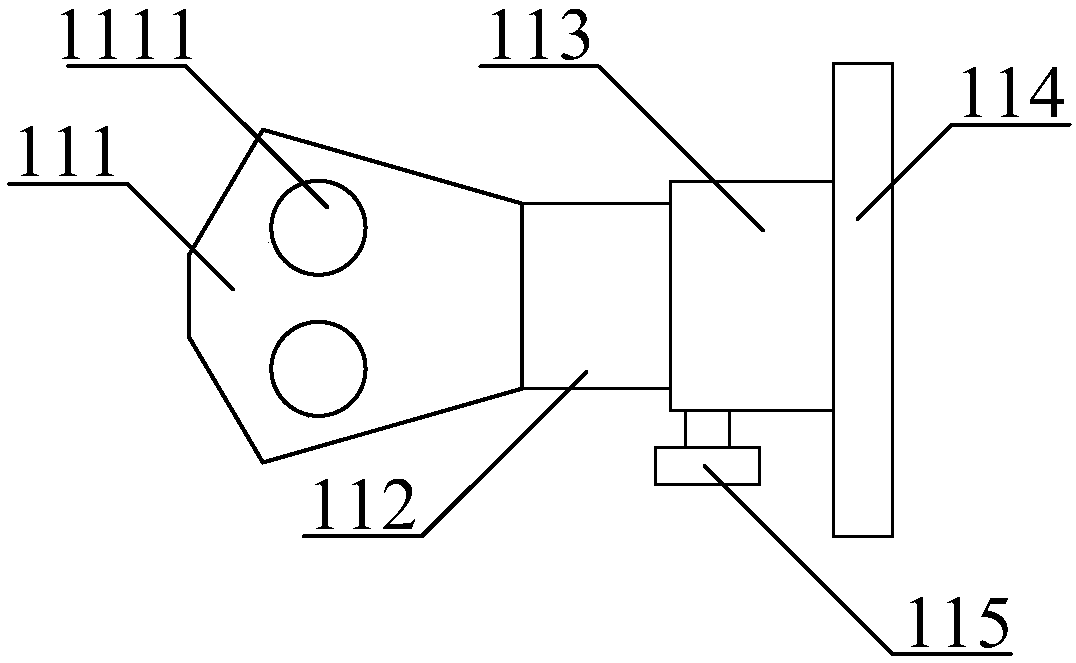

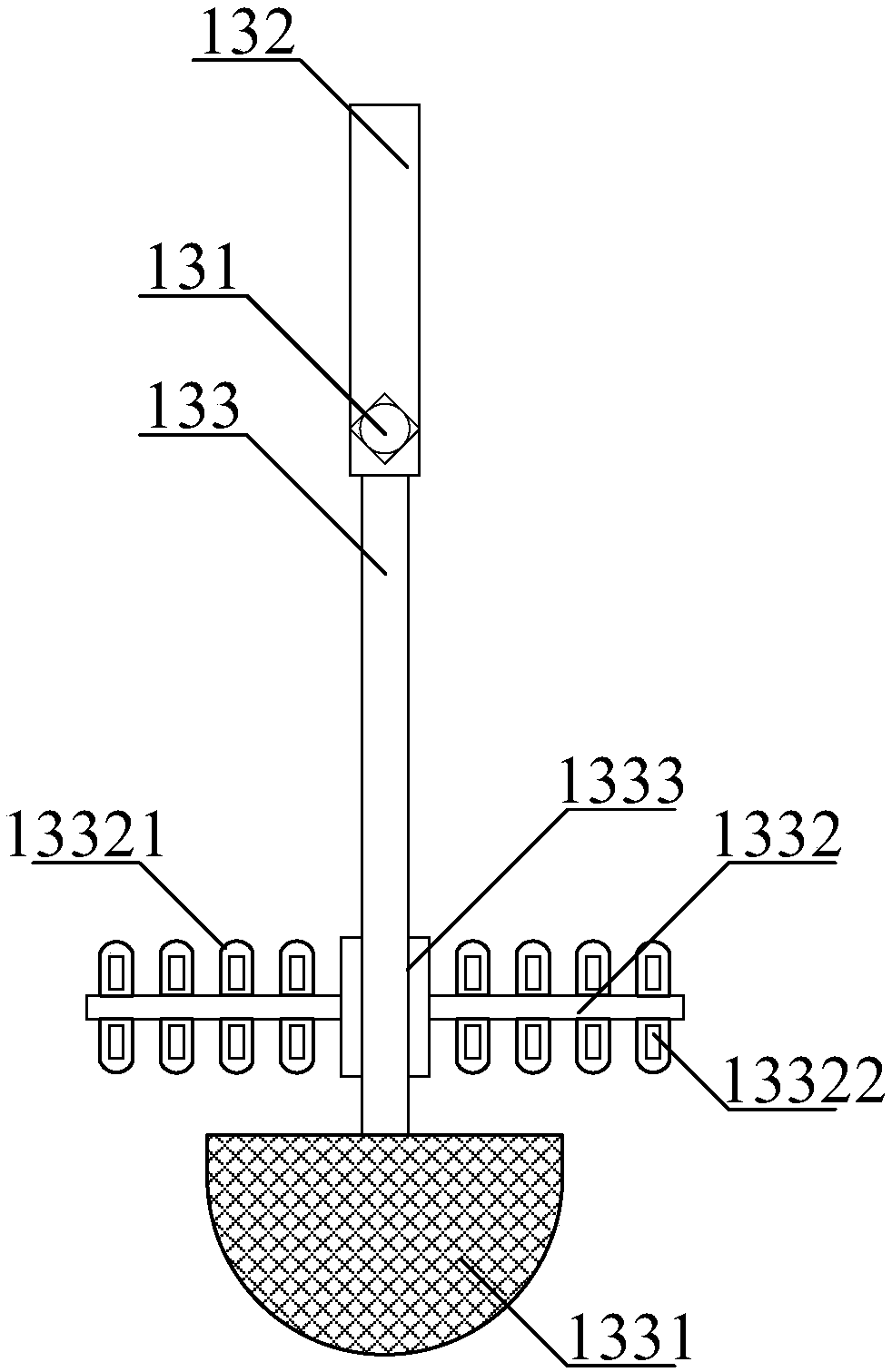

[0035] The present invention provides a multi-functional stirring equipment for aluminum alloy production, which includes a stirring motor 1, a support plate 2, an upper cover 3, a quick locking device 4, a stirring shell 5, a tripod 6, a feeding hopper 7, and a detachable stirring Frame 8, main shaft 9, sleeve coupling 10, replaceable stirring blade 11, stirring shaft 12 and salvage filter screen structure 13, the stirring motor 1 is installed on the upper middle position of the upper cover 3 through the support plate 2 bolts; The upper cover 3 is installed on the top of the stirring shell 5 through the quick lock 4; the bottom of the stirring shell 5 is installed on the bottom of the stirring shell 5 with bolts at an angle of one hundred and twenty between the described foot frame 6 and the foot frame 6; The feed hopper 7 runs through the inner right side of the upper cover 3; the feed hopper 7 and the upper cover 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com