Optimization method of position of steel-concrete combined section of large-span cable-stayed bridge based on fatigue service life assessment

A technology of steel-concrete combination and fatigue life, which is applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as fatigue life, complex force of steel-concrete combination section, and potential safety hazards in design, so as to ensure safety Sex, the effect of solving fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

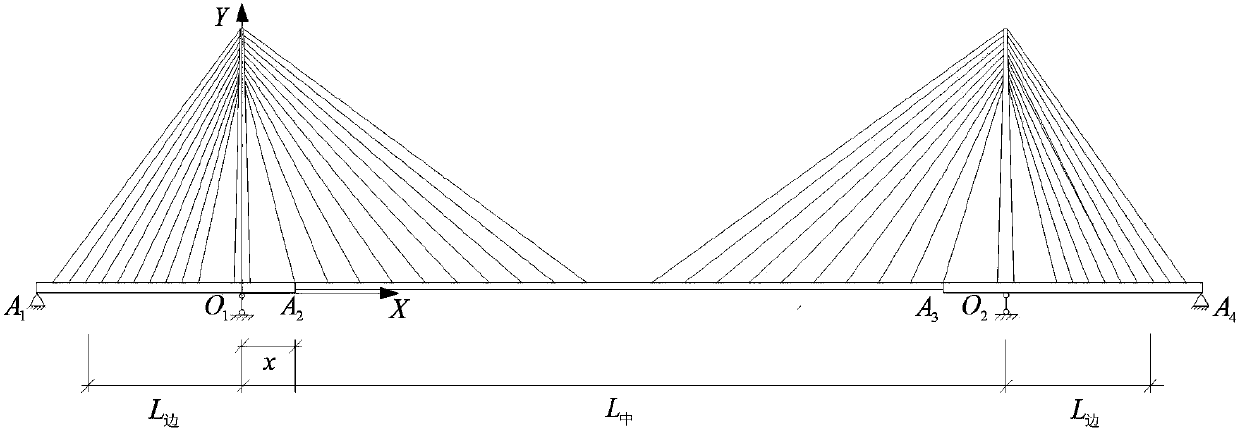

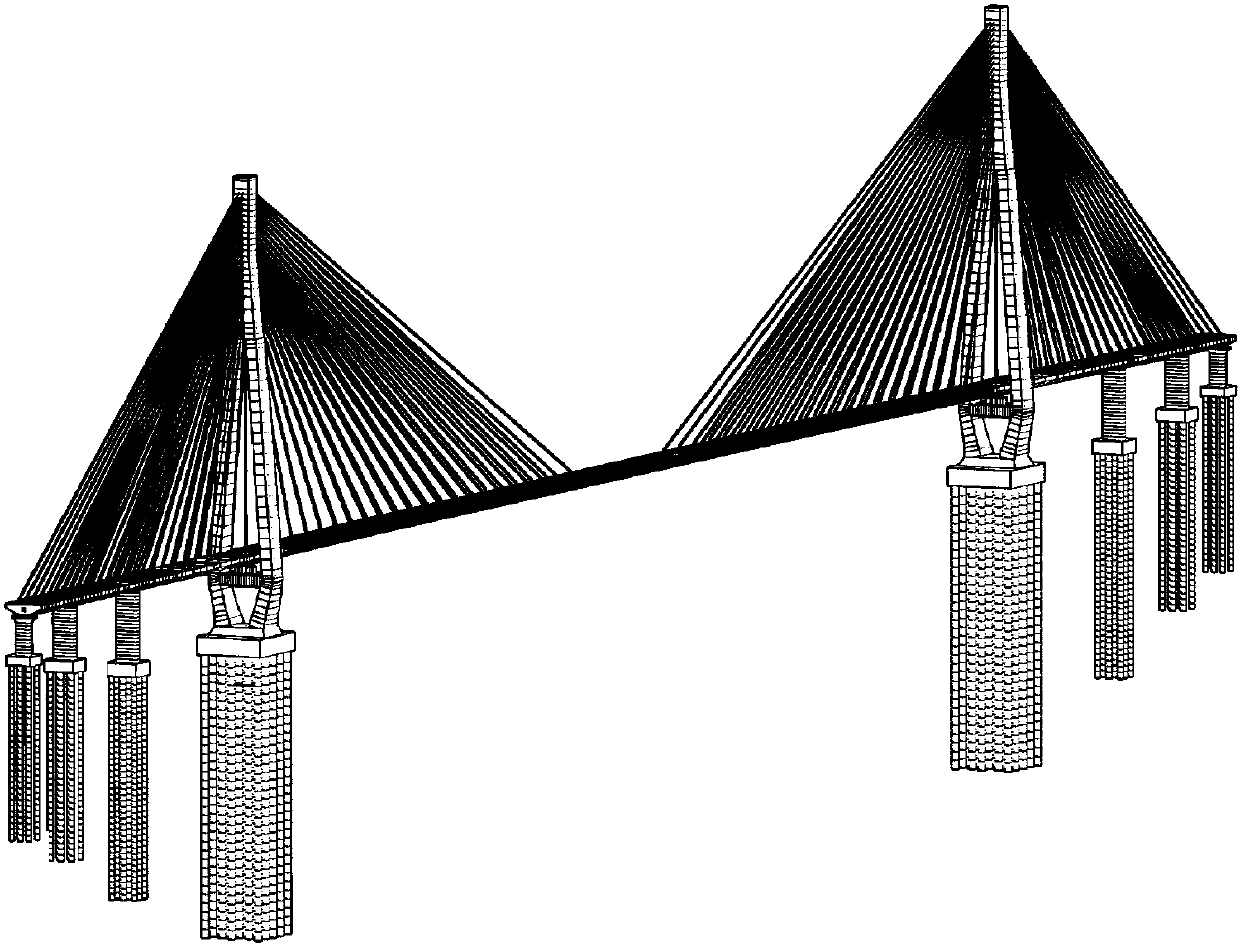

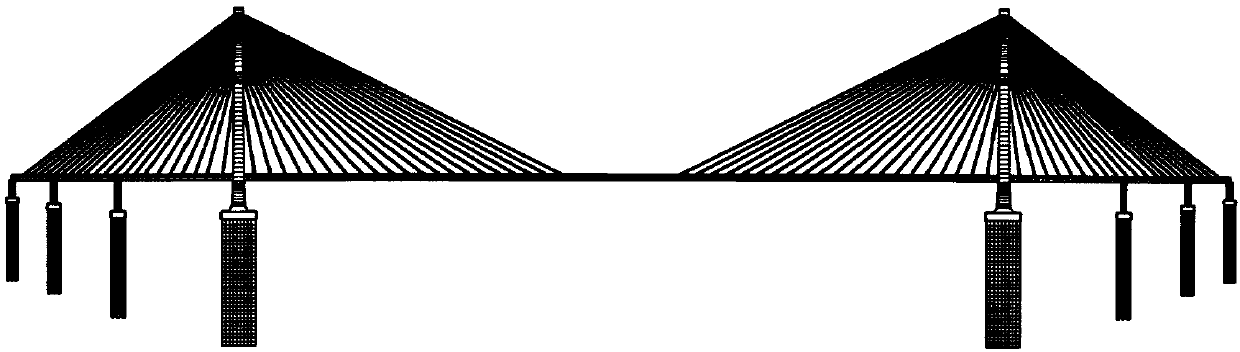

[0052] Below through embodiment, in conjunction with accompanying drawing, the technical solution of the present invention is described in further detail, a kind of method for optimizing the location of steel-concrete joint section of long-span cable-stayed bridge based on fatigue life evaluation, comprises the following steps:

[0053] 1. Establish the objective function for the optimization of the position of the steel-concrete joint section:

[0054] The present invention determines the position of the steel-concrete joint section mainly considering four factors: the section bending moment and shear force under the static force at the steel-concrete joint section; the fatigue life of the shear force connector of the steel-concrete joint section; Influence; the influence of the location of the steel-concrete joint section on the cost of the structure.

[0055] 1.1 Bending moment and shear force of steel-concrete joint section section

[0056] From the perspective of structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com