DC line fault detection method and device

A technology for DC line faults and DC lines, which is applied in the direction of measuring devices, fault locations, and measuring electricity, can solve the problems of low sensitivity of DC line faults, inability to accurately detect whether DC line faults occur, and extract fault characteristics, etc., to improve fault detection. The detection speed, simple and reliable implementation process, and the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

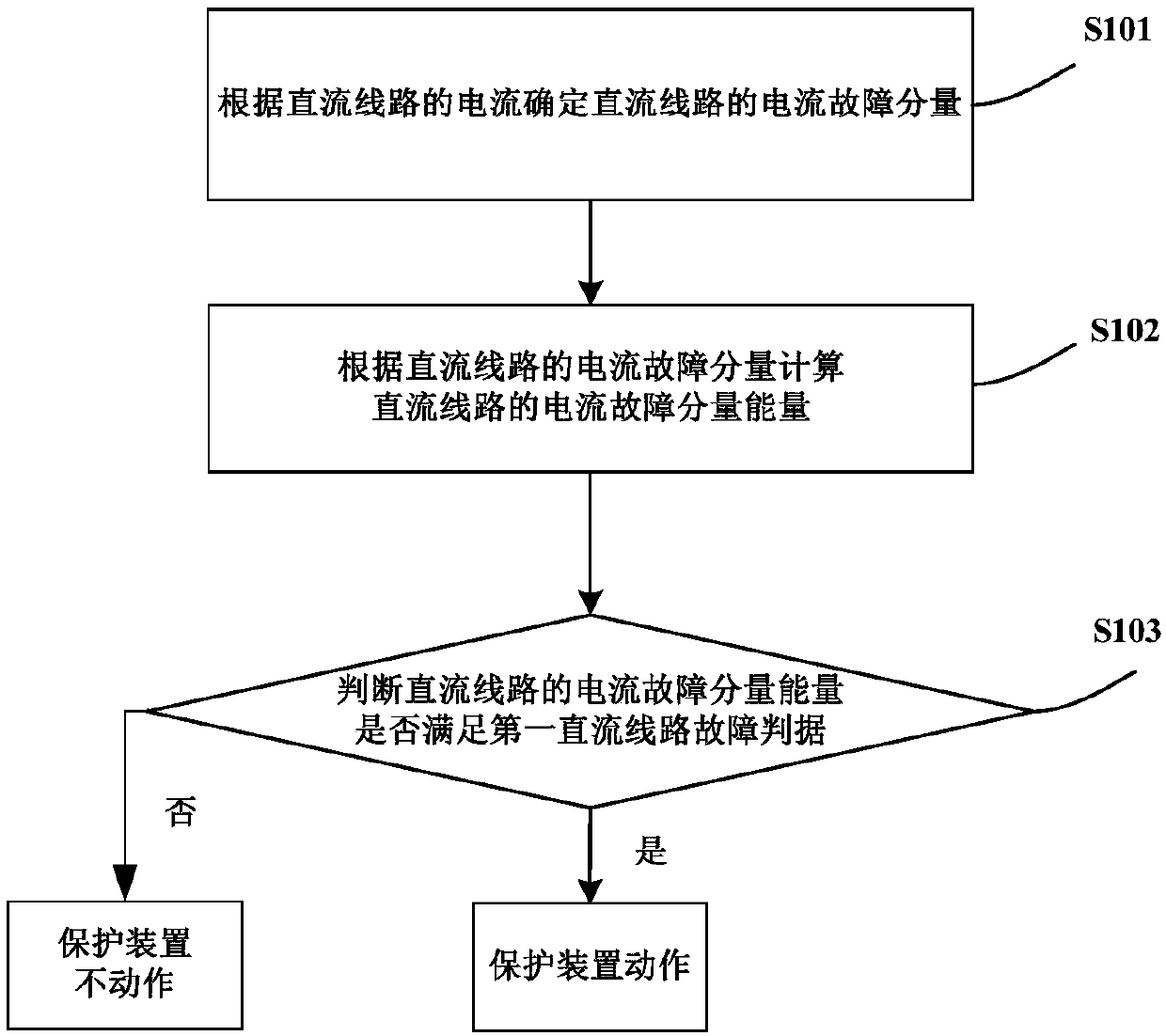

[0065] Embodiment 1 of the present invention provides a DC line fault detection method, the specific flow chart of the DC line fault detection method is as follows figure 1 As shown, the specific process is as follows:

[0066] S101: Determine the current fault component of the DC line according to the current of the DC line;

[0067] S102: Calculate the current fault component energy of the DC line according to the current fault component of the DC line determined in S101;

[0068] S103: Judging whether the current fault component energy of the DC line calculated in S102 satisfies the first DC line fault criterion, if the first DC line fault criterion is met, it indicates that the DC line is faulty, and the protection device operates; otherwise, it indicates that the DC line No fault occurs, the protection device does not operate.

[0069] In the above S101, the specific process of determining the current fault component of the DC line according to the current of the DC lin...

Embodiment 2

[0101] Embodiment 2 of the present invention provides a DC line fault detection method, the specific flow chart of the DC line fault detection method is as follows Figure 4 As shown, the specific process is as follows:

[0102] S201: Determine the current fault component of the DC line according to the current of the DC line;

[0103] S202: Calculate the current fault component energy of the DC line according to the current fault component of the DC line determined in S201;

[0104] S203: Judging whether the current fault component energy of the DC line calculated in S202 satisfies the second DC line fault criterion, if it meets the second DC line fault criterion, it indicates that the DC line has a fault and the protection device operates; otherwise, it indicates that the DC line has not occurred Fault, the protection device does not operate.

[0105] In the above S201, the specific process of determining the current fault component of the DC line according to the current ...

Embodiment 3

[0137] Embodiment 3 of the present invention takes Figure 5 The four-terminal flexible DC power grid shown is taken as an example to illustrate the specific process of the DC line fault detection method:

[0138] Figure 5 The four AC systems in Kangbao, Zhangbei, Fengning, and Beijing are respectively connected to the DC power grid, and the four AC systems are all connected to the corresponding converter stations. The converter stations are connected to each other through the DC busbar and the DC line. The line voltage level is ±500kV.

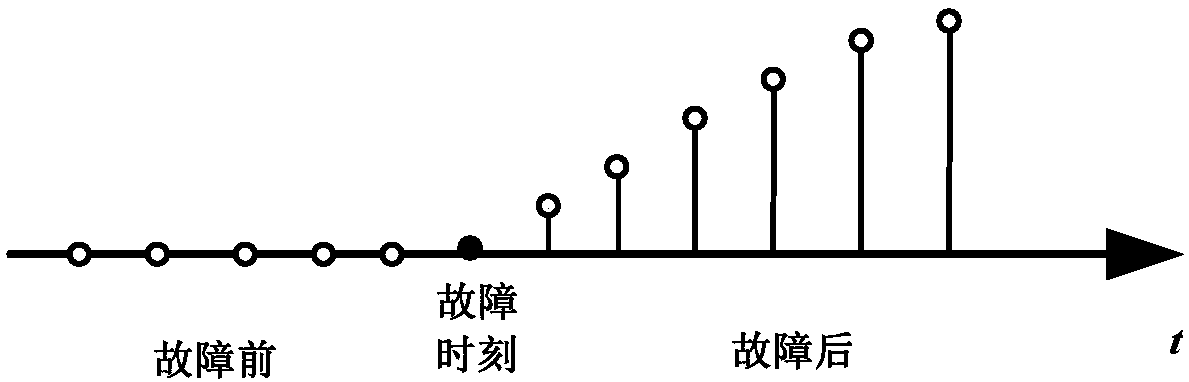

[0139] right Figure 5 The current fault component is simulated when a unipolar 300-ohm ground fault occurs at the midpoint of the Zhongkangbao-Fengning line. The specific simulation waveform diagram is as follows Figure 6 shown, from Figure 6 It can be seen that the current fault component remains stable after increasing from 0 to 0.8kA within 5ms after the fault.

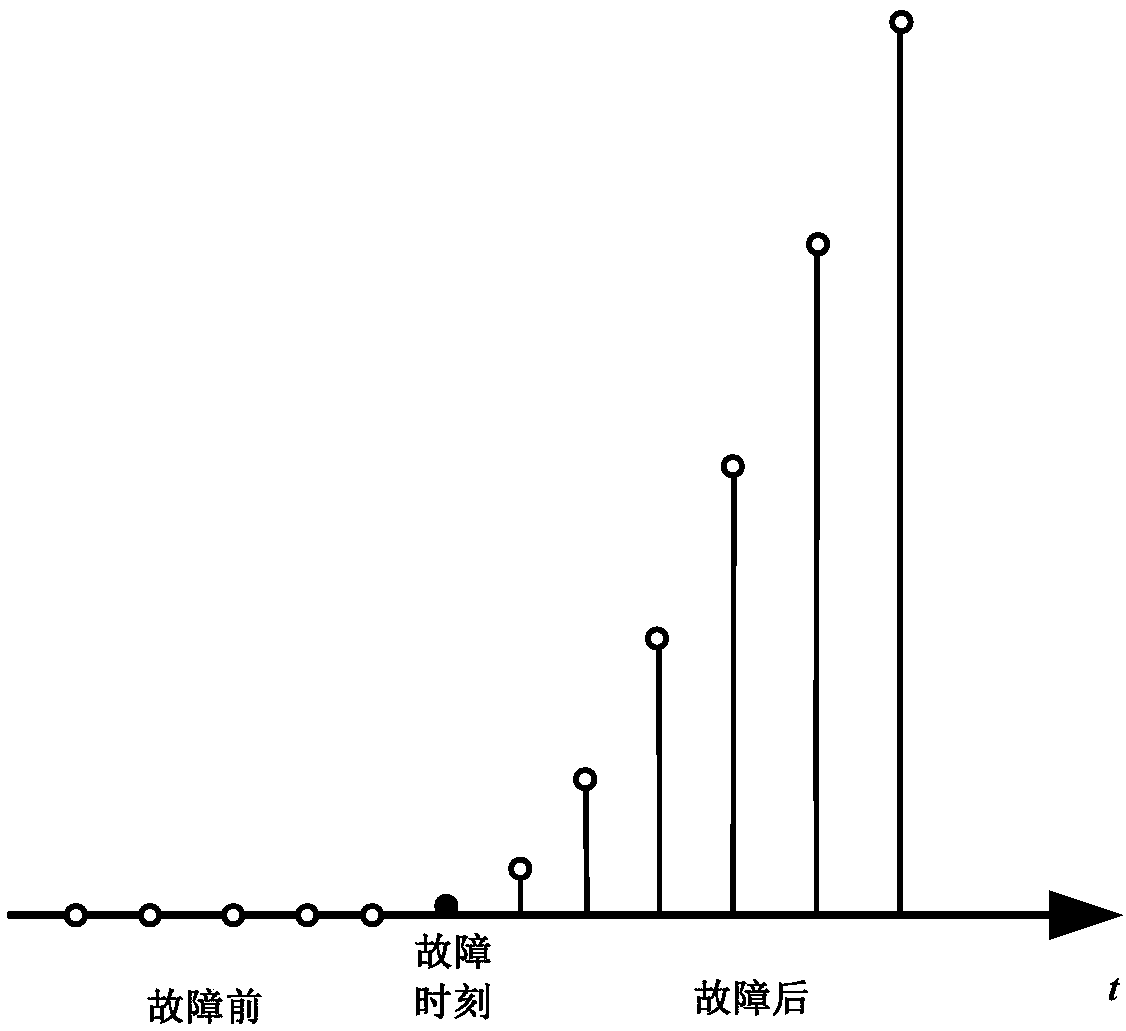

[0140] right Figure 5 The current fault component energy is simula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com