Automobile, automobile engine, engine oil cooling equipment and manufacturing method thereof

An automobile engine and engine oil cooling technology, which is applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problems of increased design difficulty, complicated injection molding and demoulding of filter covers, etc., and achieves reduced use requirements and simple mechanism , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

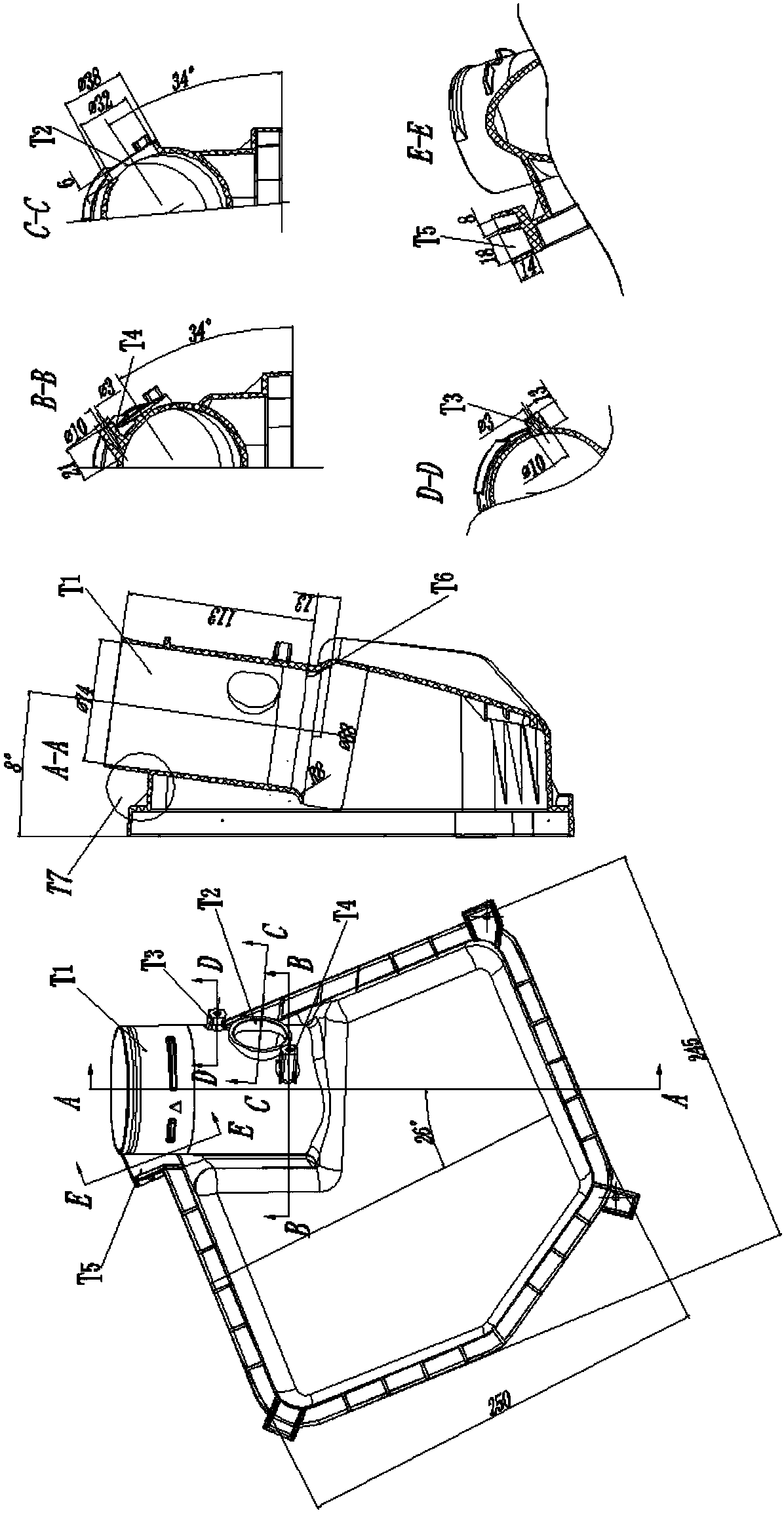

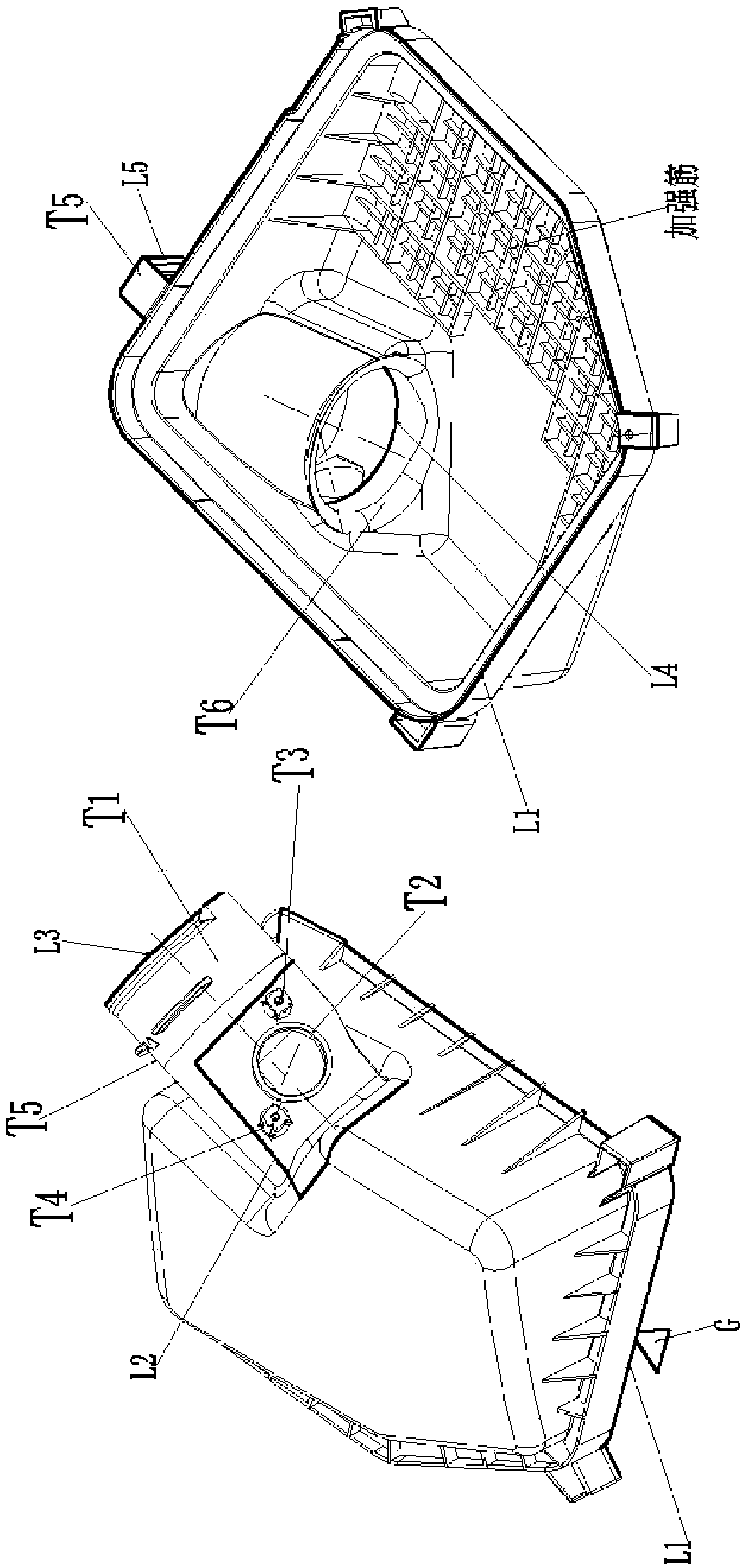

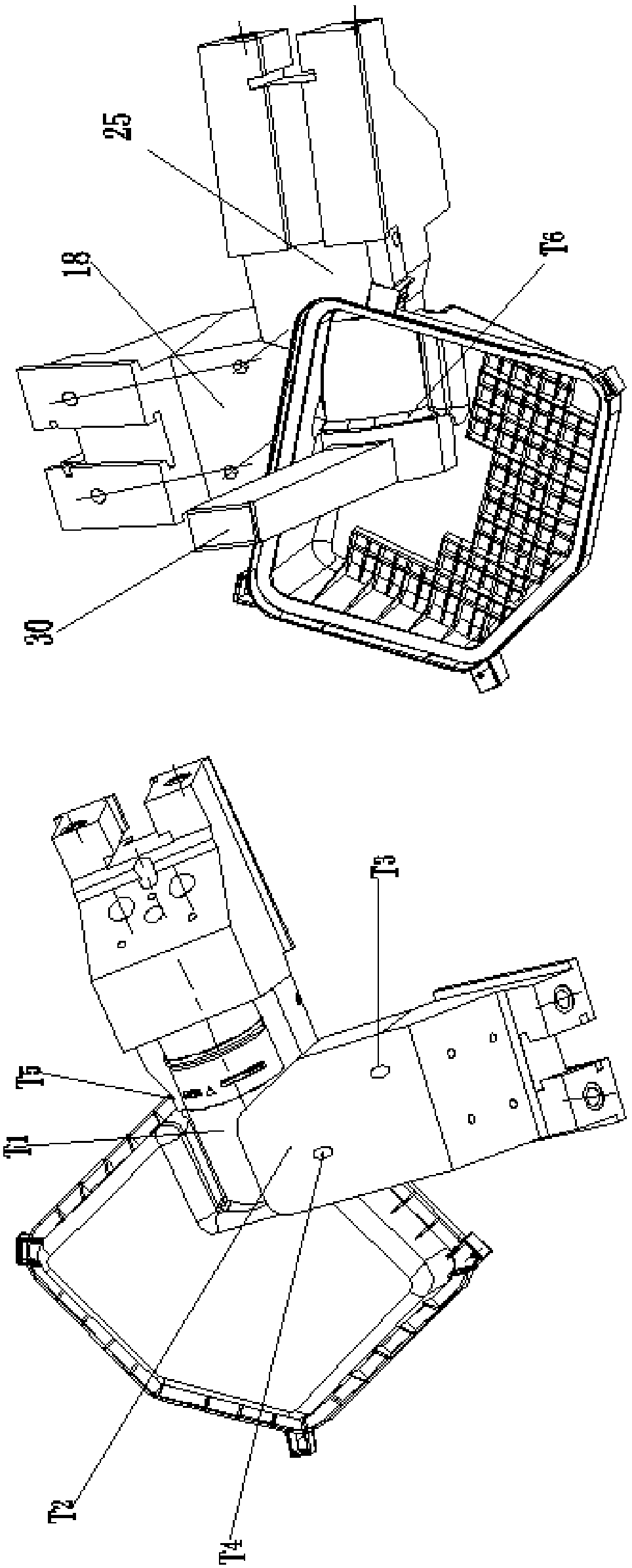

[0021] Figure 1-4 Shown is the relevant explanatory drawing of the present invention; Certain automobile engine engine oil cooling equipment filter cover product such as figure 1 As shown, the material is modified plastic ABS+20%PC+G, the shrinkage rate is 0.6%, (PC / ABS German Bayer FR2010 injection grade is easy to flow and flame retardant); the average wall thickness of the product is 3mm; the structure of the product is composed of two parts, The main body of the filter box cover and the 7 features on the box cover T1~T7T1 is the intake manifold, T2 is the sub-pipe interface on the intake manifold; T3 and T4 are the fastening screw columns of the sub-pipe joints; T5 is the main body of the box cover. The feature of inserting holes on one side; T6 is a circular arc transition section extending from the central pipe of the manifold to the center of the box cover; T7 is the undercut area formed between the feature of T1 and the edge of the main body of the box cover; the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com