Basket-style steel box arch rib production method

A manufacturing method and a basket-type technology, applied in the field of bridge manufacturing, can solve the problems of different arch ribs, difficult linear control, long technical preparation period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

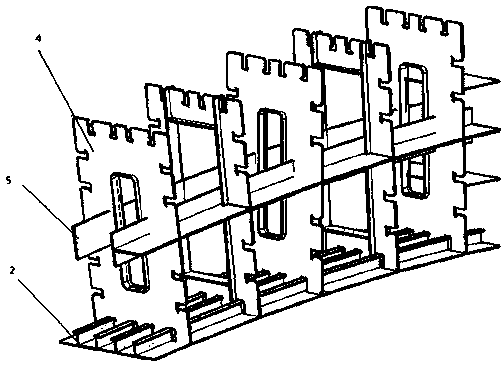

[0031] Such as Figure 1 to Figure 3 A method for manufacturing the arch rib of a basket-type steel box is shown, and the specific manufacturing method is as follows:

[0032] S1: Three-dimensional lofting of arch ribs, drawing of construction drawings:

[0033] S1.1: Three-dimensional lofting: find out the key sections according to the design plan, ensure that the geometric dimensions of the key sections meet the design requirements, and complete the three-dimensional lofting through the smooth transition between several key sections;

[0034] S1.2: Drawing of construction drawings: each arch rib is a spatial structure, and it is impossible to display all information on the plan. The main view of the construction drawing should be a schematic diagram to help understand th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com