Simply supported beam bridge deck plate continuous structure and construction method thereof

A simply supported girder bridge and construction method technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of poor stability, easy water seepage, easy damage to joints, etc., to achieve good durability, short construction period, labor low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

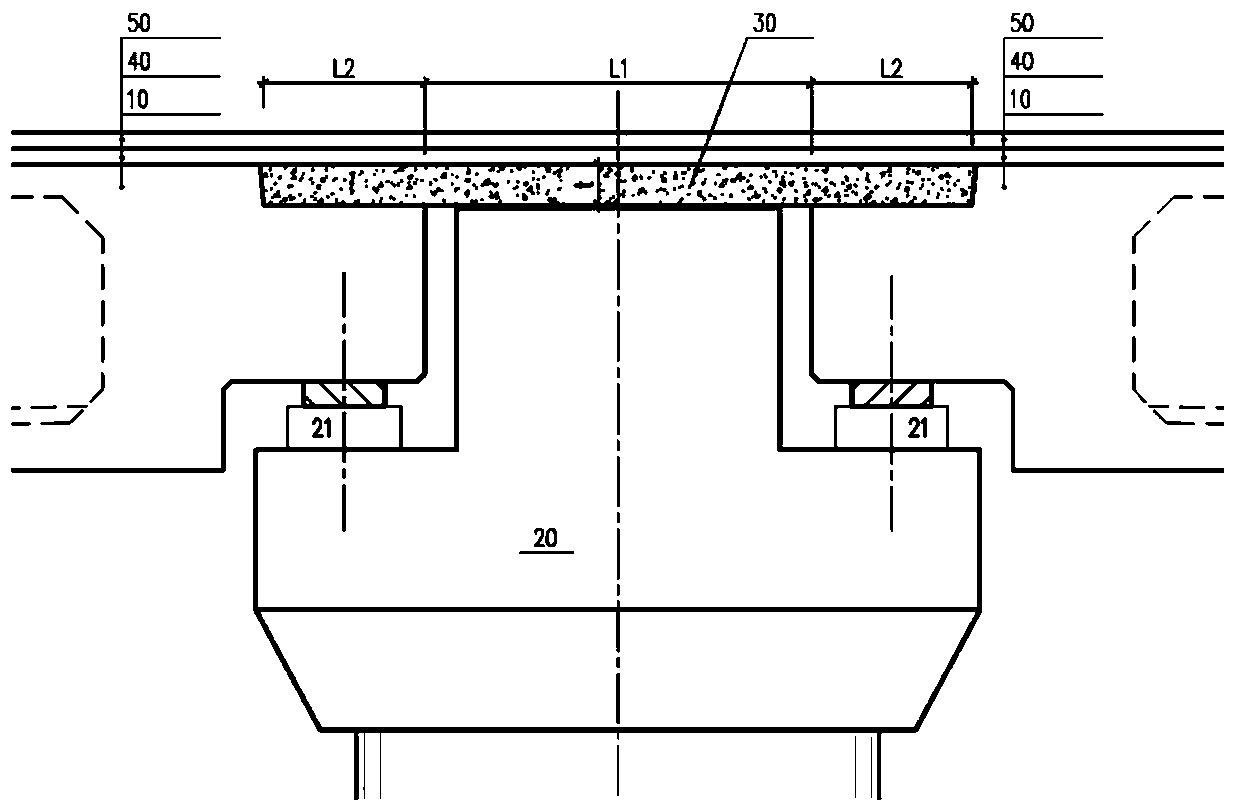

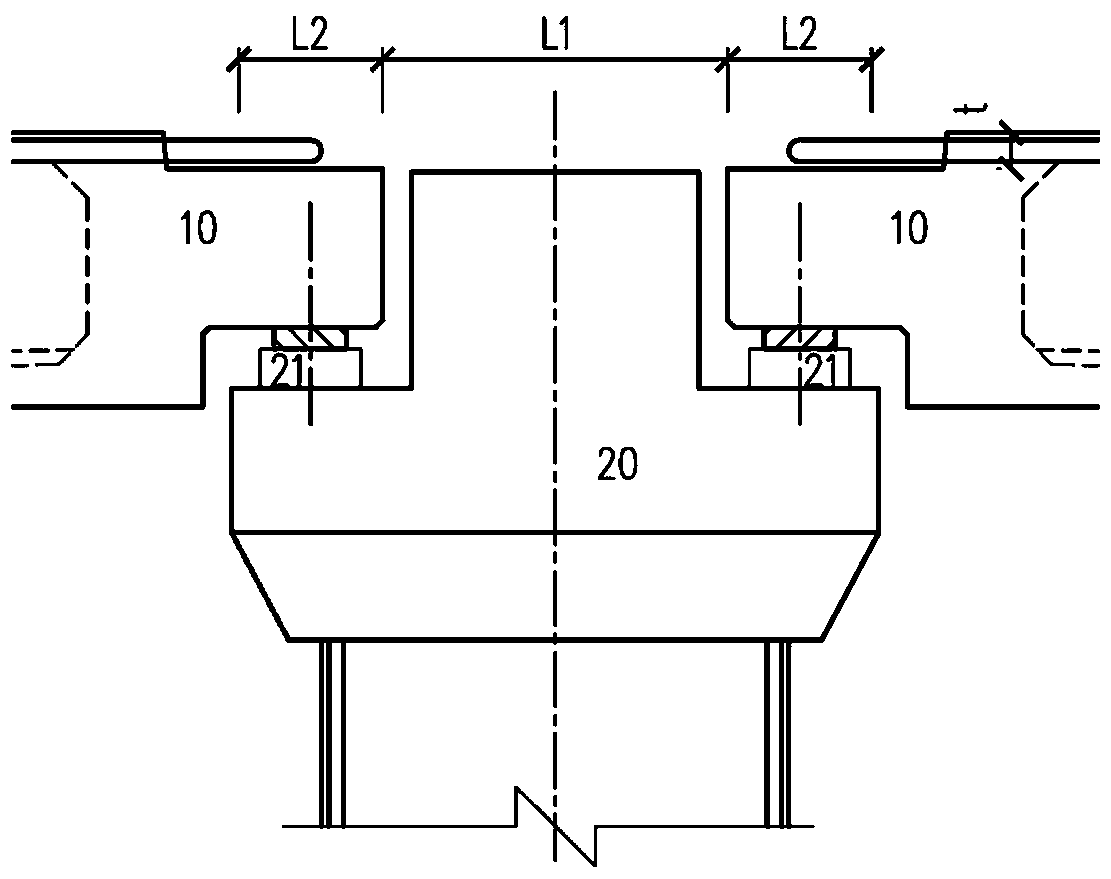

[0029] Supports 21 are respectively provided on the two side wings of the cover beam 20 (inverted T-shaped structure). After the pouring or hoisting of the cover beam 20 is completed, the support 21 is installed, and the main beam 10 is installed above the cover beam 20 through the support 21 to form a simply supported system. During specific implementation, steel bar joints are reserved during the prefabrication of the main girder 10, and after two adjacent main girders 10 are hoisted in place, welded steel bars are erected and concrete is poured to form a continuous slab. Casting continuous slabs on site can effectively avoid the defects of easy cracking and water leakage at the joints, and the structure is simple and the construction is convenient.

[0030] The length of the continuous plate 30 is composed of a slot width L1 and two isolation lengths L2. The slit width L1 refers to the horizontal distance between the beam ends of adjacent main beams 10 on both sides. In th...

Embodiment 2

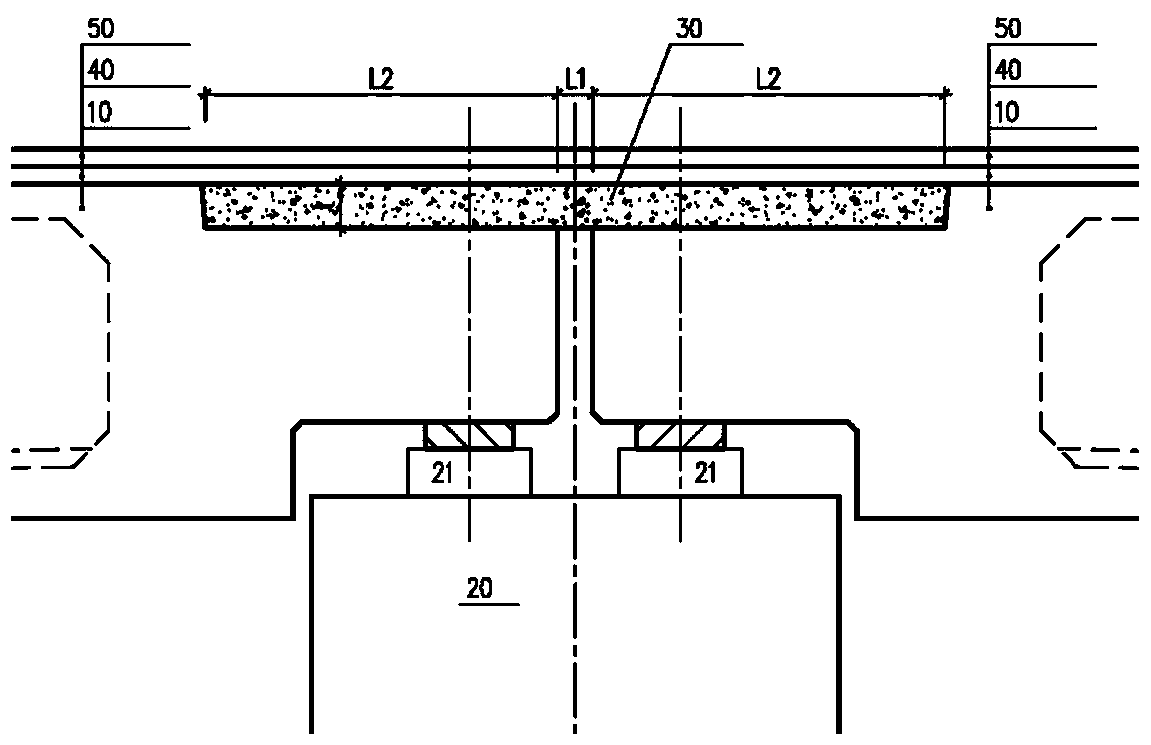

[0034] The difference between the second embodiment and the first embodiment is that the cross-sectional structure of the cover beam 20 is replaced by a rectangular structure, and two sets of supports 21 are arranged at the top of the cover beam 20 (rectangular structure).

[0035] The length of the continuous plate 30 is constituted by the sum of the slot width L1 and the two isolation lengths L2. The slit width L1 refers to the horizontal distance between the beam ends of adjacent main beams 10 on both sides. In this embodiment, since the rectangular structure is arranged below the two main beams 10, the slit width L1 only refers to The horizontal distance between beam ends of adjacent main beams 10 on both sides does not include the width of the rectangular structure.

[0036] Adopt the construction method of described simply supported beam bridge deck continuous structure (see image 3 with Figure 4 ), the image 3 with Figure 4 Only the construction steps when the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com