PA composite with high-low temperature resistance, high dimension stability and UV aging resistance for outdoor ventilator and its preparation method

A technology with dimensional stability and high and low temperature resistance, applied in the polymer field, can solve the problems of restricting the application of reinforced flame retardant nylon and dimensional instability, and achieve the effect of improving dimensional stability, good weather resistance and thermal conductivity, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

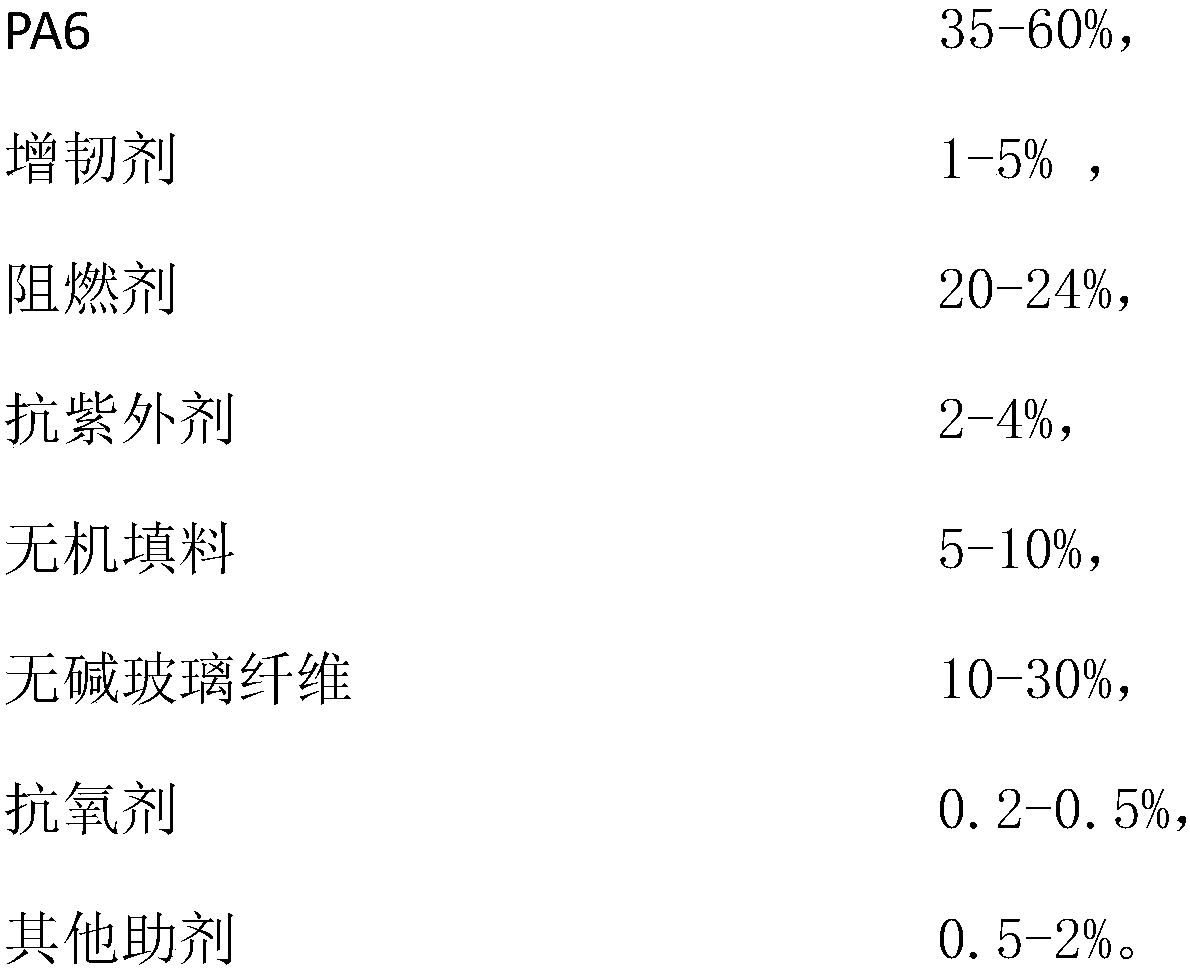

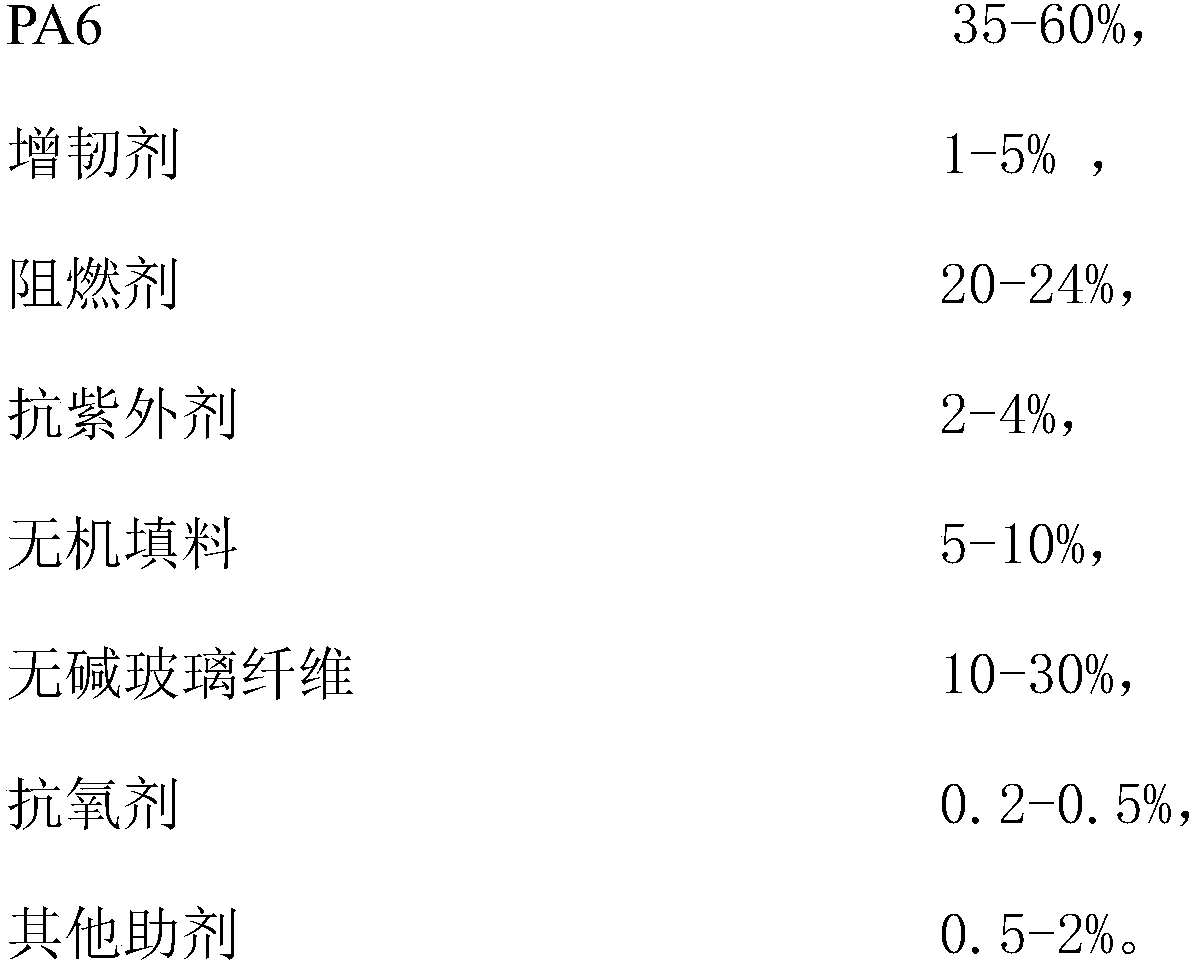

Method used

Image

Examples

Embodiment 1

[0025] Take by weighing the following dried nylon raw materials and other raw material auxiliary agents, and the percentages by weight are: relative viscosity is 2.8 PA6, 40%; toughening agent 4%; flame retardant, 20%; anti-ultraviolet agent (benzotriazole class and hindered amines), 2.5%; alkali-free glass fiber yarn, 25%; inorganic filler (silica powder, glass microsphere), 7%; antioxidant, 0.3%; other additives, 1.2%. The mixture is mixed in a high-speed mixer for 5-10 minutes, mixed evenly, melted in an extruder at 220-250° C., added with glass fiber, extruded and granulated to obtain a composite material.

Embodiment 2

[0027] Take by weighing the following dried nylon raw materials and other raw material additives, and the percentages by weight are: relative viscosity is 2.8 PA6, 40%; toughening agent 4%; flame retardant, 20%; anti-ultraviolet agent (ultrafine carbon black and hindered amines), 2.5%; alkali-free glass fiber yarn, 25%; inorganic fillers (microsilica powder, talcum powder), 7%; antioxidants, 0.3%; other additives, 1.2%. The mixture is mixed in a high-speed mixer for 5-10 minutes, mixed evenly, melted in an extruder at 220-250° C., added with glass fiber, extruded and granulated to obtain a composite material.

Embodiment 3

[0029] Take by weighing the following dried nylon raw materials and other raw material auxiliary agents, and the percentages by weight are: relative viscosity is 2.8 PA6, 40%; toughening agent 4%; flame retardant, 20%; anti-ultraviolet agent (benzotriazole class and hindered amines), 2.5%; alkali-free glass fiber yarn, 25%; inorganic filler (silica powder, quartz powder), 7%; antioxidant, 0.3%; other additives, 1.2%. The mixture is mixed in a high-speed mixer for 5-10 minutes, mixed evenly, melted in an extruder at 220-250° C., added with glass fiber, extruded and granulated to obtain a composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com