Synthetic method of 7-tert-butyl 3-ethyl 8-methyl-5,6 dihydrotriazolopyrazine 3,7(8H) phthalate ester

A technology of dicarboxylate and methylpyrazine, applied to the production of 7-tert-butyl 3-ethyl 8-methyl 5,6 dihydrotriazolopyrazine 3,7(8H) dicarboxylate In the field of synthesis, achieve the effect of reasonable reaction process design and cost-saving synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0010] Synthesis of hydrazino-3-methylpyrazine

[0011]

[0012] Add 748 g of hydrazine hydrate to 300 g of compound 1 in ethanol at 20°C, and stir magnetically at 90°C for 12 hours after the addition. After the raw materials have been completely reacted, the reaction liquid is concentrated in vacuum, and the filter cake is beaten with about 1 L of dichloromethane to remove excess hydrazine hydrate. The filter cake was transferred to a one-necked bottle and dried under vacuum. 400 g of compound 2 was obtained as a yellow solid.

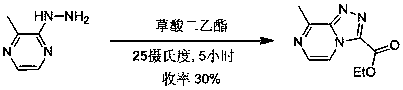

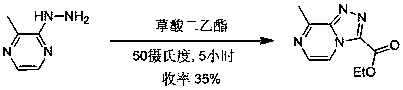

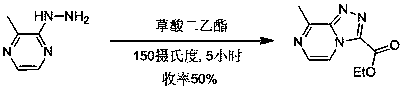

[0013] Synthesis of Ethyl-8-Methyl-[1,2,4]triazolo[4,3-a]pyrazine-3-carboxylate

[0014]

[0015] 435 g of Compound 2 was dissolved in 5 L of diethyl oxalate, and the reaction solution was magnetically stirred at 25°C for 5 hours. After the raw material is completely reflected, the oil pump spins the diethyl oxalate away, and the solid is beaten and filtered with about 2L of dichloromethane. The filter cake is a by-product and washed twice wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com