Polishing device with cleaning assembly

A polishing device and component technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems of lower polishing quality of the door panel surface, board parts flying out of the machine, board parts damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

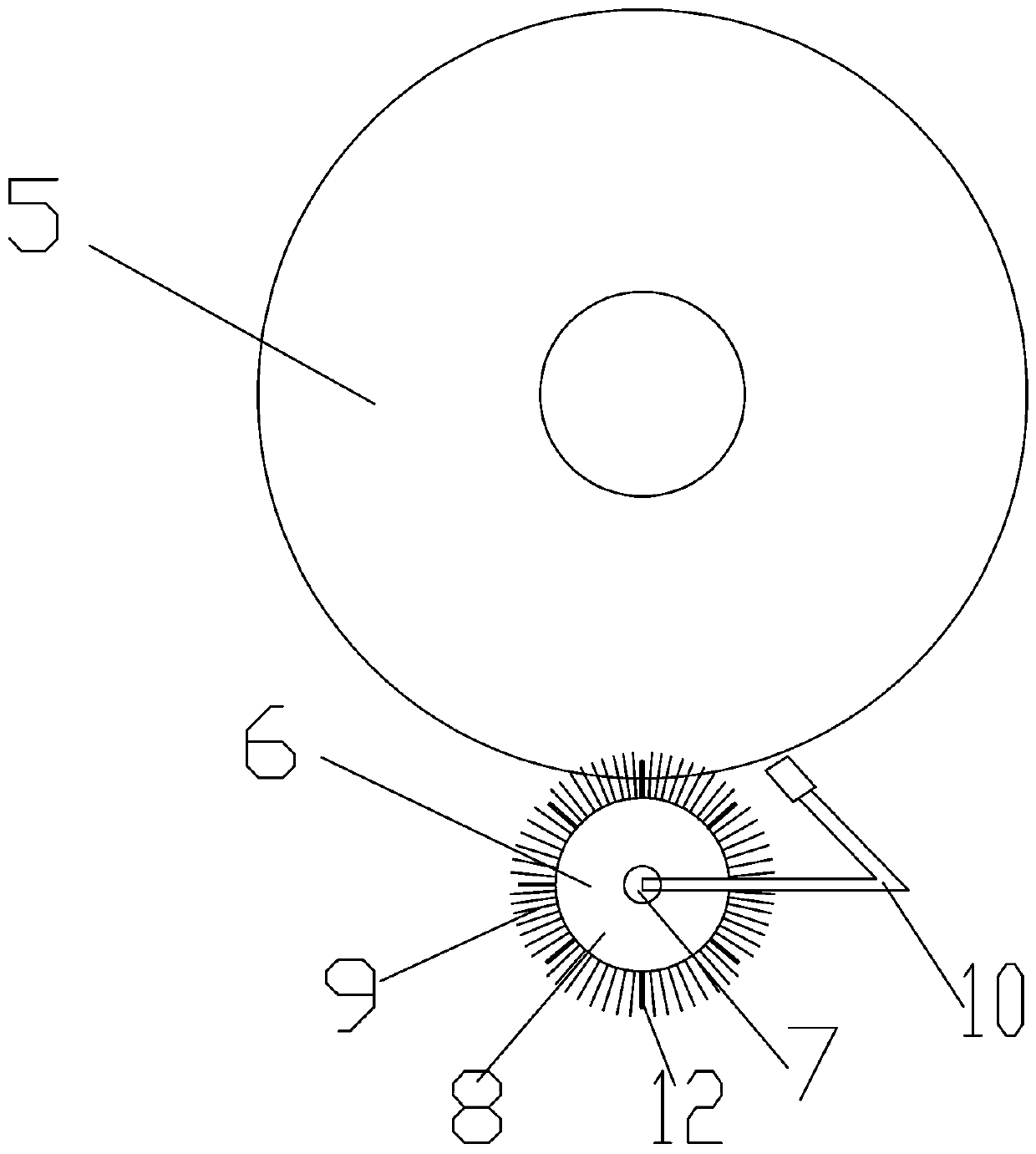

[0014] like figure 1 , figure 2 As shown, a polishing device with a cleaning assembly provided in this embodiment includes a mounting bracket 1, a working platform 2, and a slide rail 3 that drives the working platform 2 to move. The mounting bracket 1 is provided with a roller shaft 4, and the roller A polishing wheel 5 is sleeved on the shaft 4, and the polishing wheel 5 is located above the working platform 2. The working platform 2 is provided with a cleaning assembly 6, and the cleaning assembly 6 is located below the polishing wheel 5. The cleaning assembly 6 includes a rotating shaft 7 and a rigid brush 8 sleeved on the rotating shaft 7, the rigid brush 8 is densely covered with steel wires 9, the two ends of the rotating shaft 7 are fixed with nozzles 10, and the two nozzles 10 are all facing the polishing wheel 5 and opposite Setting; the cleaning assembly 6 also includes an infrared sensor 11, and the infrared sensor 11 is an infrared sensor 11 for ensuring that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com