Threaded hole repairing drill bit assembly and threaded hole repairing method

A drill assembly and threaded hole technology, applied in the field of threaded hole repair drill assembly, can solve problems such as affecting repair, no space, and inconvenient positioning operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

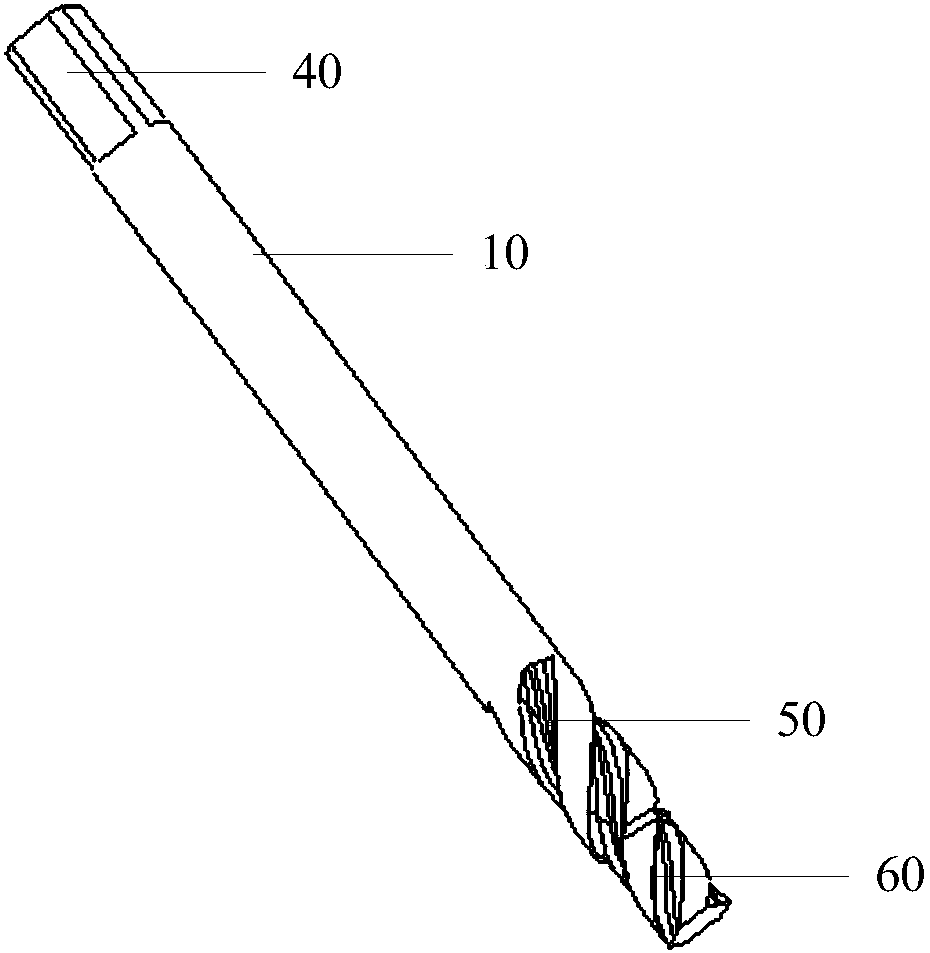

[0051] Figure 1a It is a structural schematic diagram of the threaded hole repair drill assembly provided by Embodiment 1 of the present invention used on parts. Figure 1b It is provided by Embodiment 1 of the present invention Figure 1a Details of part A in Fig. Figure 2a It is a schematic structural view of the first rod-shaped body of the threaded hole repair drill assembly provided by Embodiment 1 of the present invention. Figure 2b It is a front view of the first rod-shaped body of the threaded hole repair drill assembly provided in Embodiment 1 of the present invention. Figure 2c It is a side view of the first rod-shaped body of the threaded hole repair drill assembly provided in Embodiment 1 of the present invention. Figure 3a It is a structural schematic diagram of the second rod-shaped body of the threaded hole repair drill assembly provided by Embodiment 1 of the present invention. Figure 3b It is a front view of the second rod-shaped body of the threaded h...

Embodiment 2

[0080] Figure 7 It is a schematic flow chart of the threaded hole repair method provided in Embodiment 2 of the present invention. Refer to attached Figure 7 As shown, Embodiment 2 of the present invention also provides a threaded hole repair method, comprising the following steps:

[0081] S1: Insert the first rod-shaped body 10 into the threaded hole to be repaired, use the guide part 60 of the first rod-shaped body 10 and the cutting tool 50 to complete the first reaming of the threaded hole, and take out the first rod-shaped body 10 .

[0082] It should be noted that, in the process of repairing the threaded hole where the thread teeth fall off in this embodiment, the first rod-shaped body 10 is firstly used. One end of the first rod-shaped body 10 has a connecting part 40 connected with the wrench 100, and the second end is provided with a wrench. For the cutting tool 50 for leveling and repairing the inner wall of the threaded hole, a guide part 60 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com