A shrinking mold for an inner slider

A technology of inner sliding block and sliding block, applied in the direction of forming tools, manufacturing tools, household appliances, etc., can solve the problems of out-of-round deformation, misalignment, unclear outline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

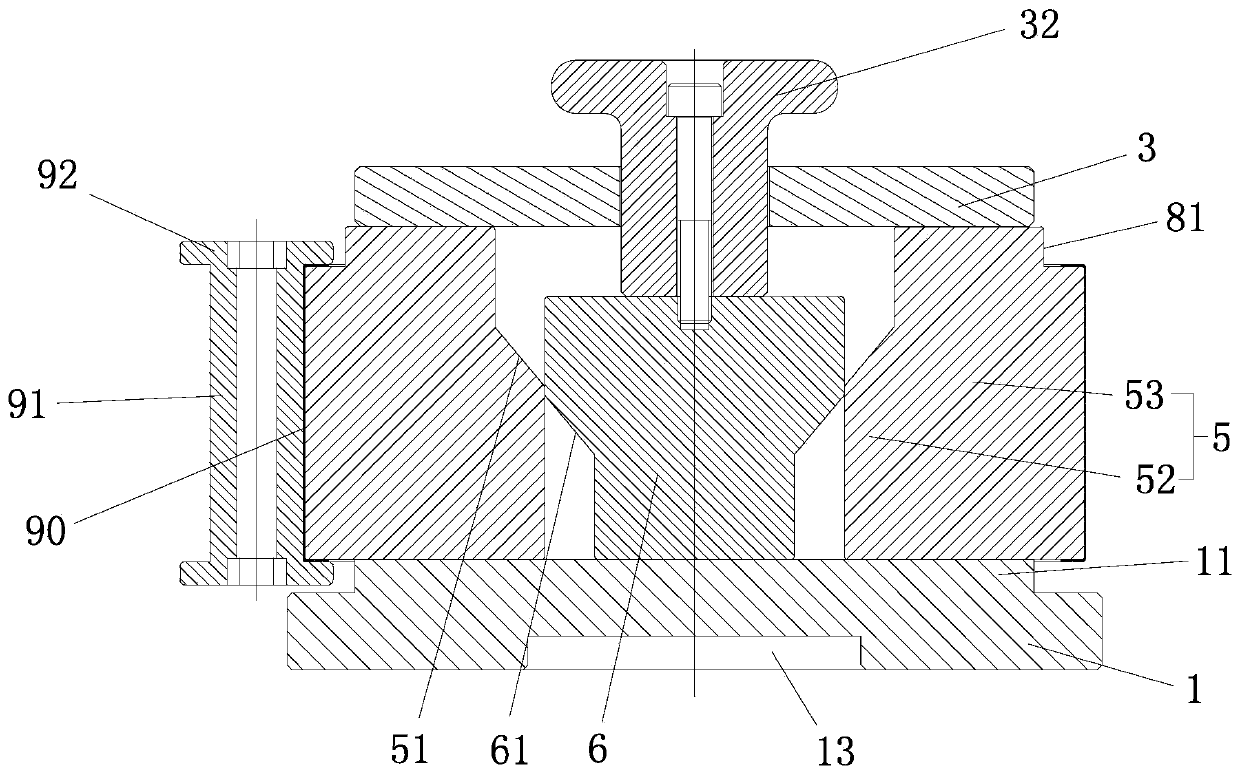

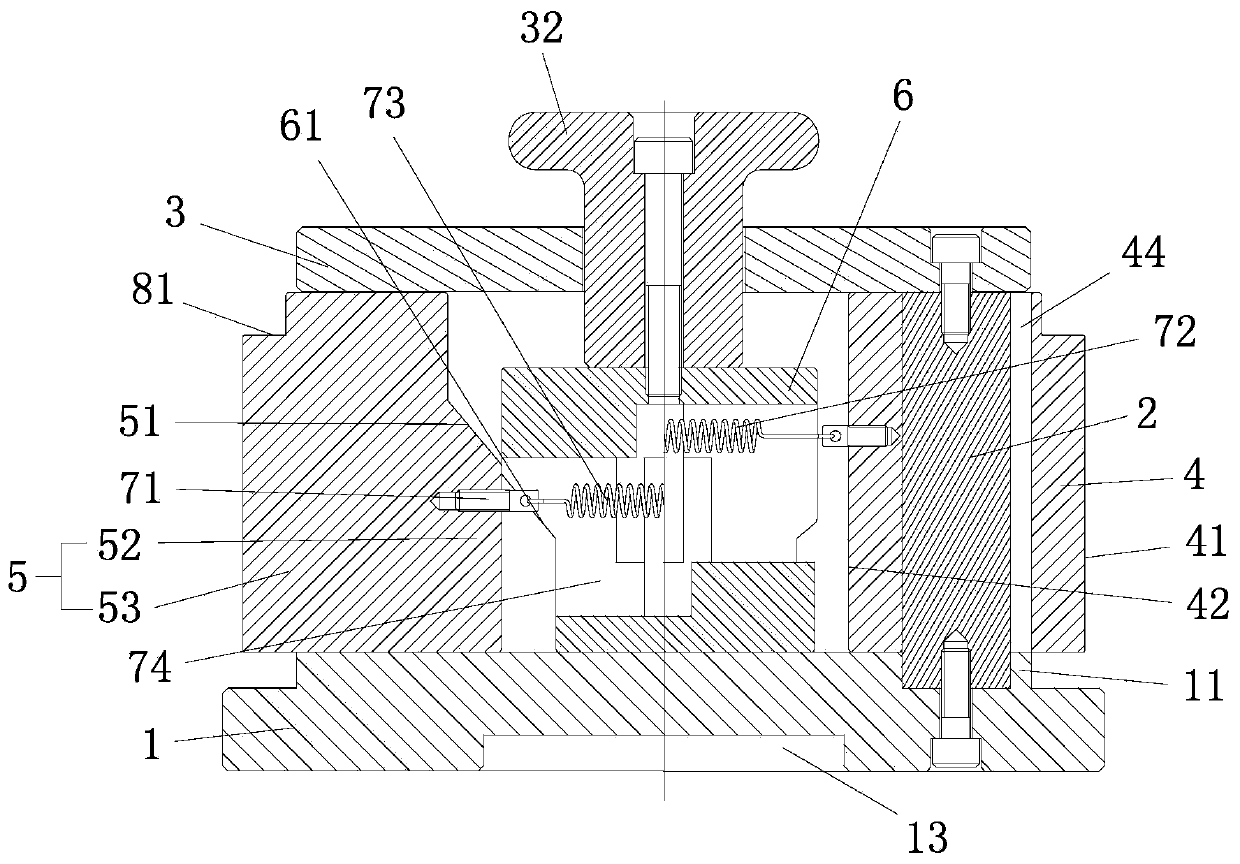

[0040] see Figure 1-Figure 14 , the inner slider shrinkage mold, including a base plate 1, a number of guide blocks 2 uniformly distributed on the base plate 1 along the circumferential direction of the center, and an upper cover plate 3 fixed on the guide block 2, characterized in that the base plate 1 and the upper cover There are several first sliders 4 between the plates 3, a second slider 5 for driving the first slider 4 to slide outward, and a wedge 6 for driving the second slider 5 to slide outward. The block 4 and the second slide block 5 are all located at the periphery of the oblique wedge 6, and a first slide block 4 is set on each guide block 2, the second slide block 5 is located between two adjacent first slide blocks 4, and the first slide block The inner surfaces of the block 4 and the second slide block 5 are connected with reset mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com