Boiling refrigerant purifying device

A purification device and refrigerant technology, applied in chemical instruments and methods, filtration circuits, filtration separation, etc., can solve problems such as inability to purify, achieve high purification efficiency, effective and stable heating, and reduce pollution

Inactive Publication Date: 2018-05-15

WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, if there is no suitable purification device, it is generally not possible to purify at the user's site or laboratory

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0044]If the above-mentioned purification device is used to purify L-1402, the maximum heating temperature of the cooling water in the heating chamber can be adjusted to 61°C, and the alarm temperature of the evaporation tank can be set to 55°C to ensure a stable and safe evaporation process.

Embodiment 2

[0046] If the purification device described above is used to purify FC-84, the alarm temperature of the evaporation tank can be set to 85°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

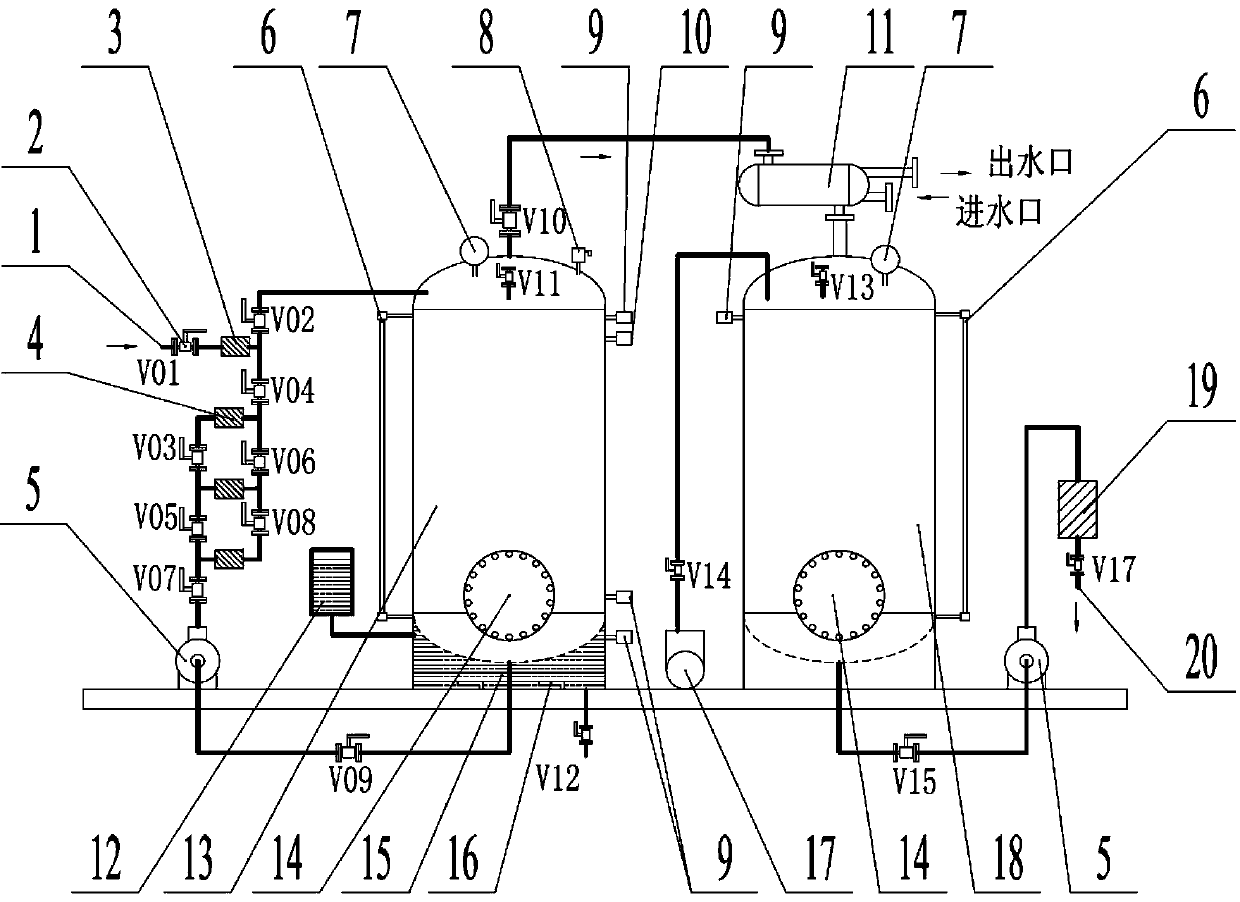

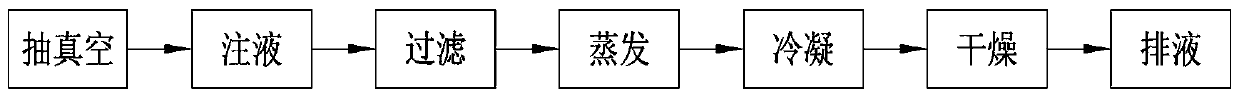

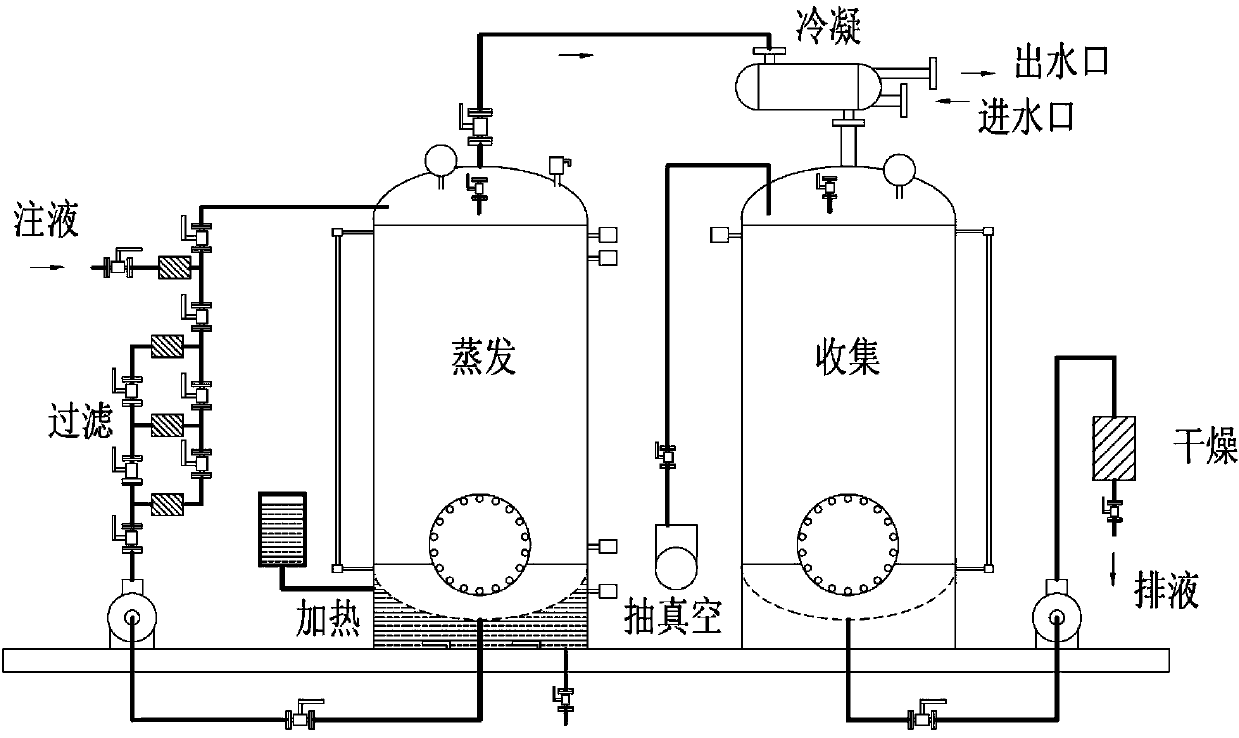

The invention discloses a boiling refrigerant purifying device. The device comprises a liquid injection port, a ball valve, a coarse filter, an evaporation tank, a condenser, a collecting tank, a magnetic pump, a dryer and a liquid discharge port which are sequentially connected; a heating cavity is arranged below the evaporation tank; a heater is arranged at the bottom of the heating cavity; a transparent water tank is connected on the heating cavity; the bottom end of the evaporation tank is connected with the magnetic pump through a pipeline; a fine filter is connected on the magnetic pump;the outlet of the fine filter is connected with the outlet of a coarse filter; and a vacuum compressor is connected on the collecting tank. According to the device, the characteristics of low boilingpoint of the boiling refrigerant is utilized, physical filtration, distillation and drying are carried out to effectively remove impurities in the boiling refrigerant, and only simple steps are needed to realize the purification of the boiling refrigerant. The device has the characteristics of high purification efficiency, strong purification capability, smooth purification process, safety, reliability, no leakage and the like, and has good maintainability.

Description

technical field [0001] The invention belongs to the field of chemical evaporative cooling, and relates to a boiling refrigerant purification device, which is especially suitable for the purification of boiling refrigerant in the chemical industry or electric power occasions using evaporative cooling schemes. Background technique [0002] During the storage or use of the boiling refrigerant, there may be water, oil or solid impurities mixed in it. The boiling refrigerant mixed with impurities may damage the compressor, damage the insulation of the equipment or block the cooling pipe, which will bring harm to the operation of the equipment. Therefore, regular cleaning is required. [0003] At present, there is no general-purpose boiling refrigerant purification device in the market, and most of the boiling refrigerant purification devices are small-scale purification devices with low efficiency. Purifying a large amount of boiling refrigerant at one time needs to be purified ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D36/00B01D1/30B01D1/00

CPCB01D36/003B01D1/0082B01D1/30

Inventor 张波蔡煜冯君华

Owner WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com