Equipment fault early warning method based on maintenance records

A technology for maintenance records and equipment failures, applied in digital transmission systems, data exchange networks, electrical components, etc., can solve problems such as waste of manpower, possibility of large recurrence, lack of scientificity in unified maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

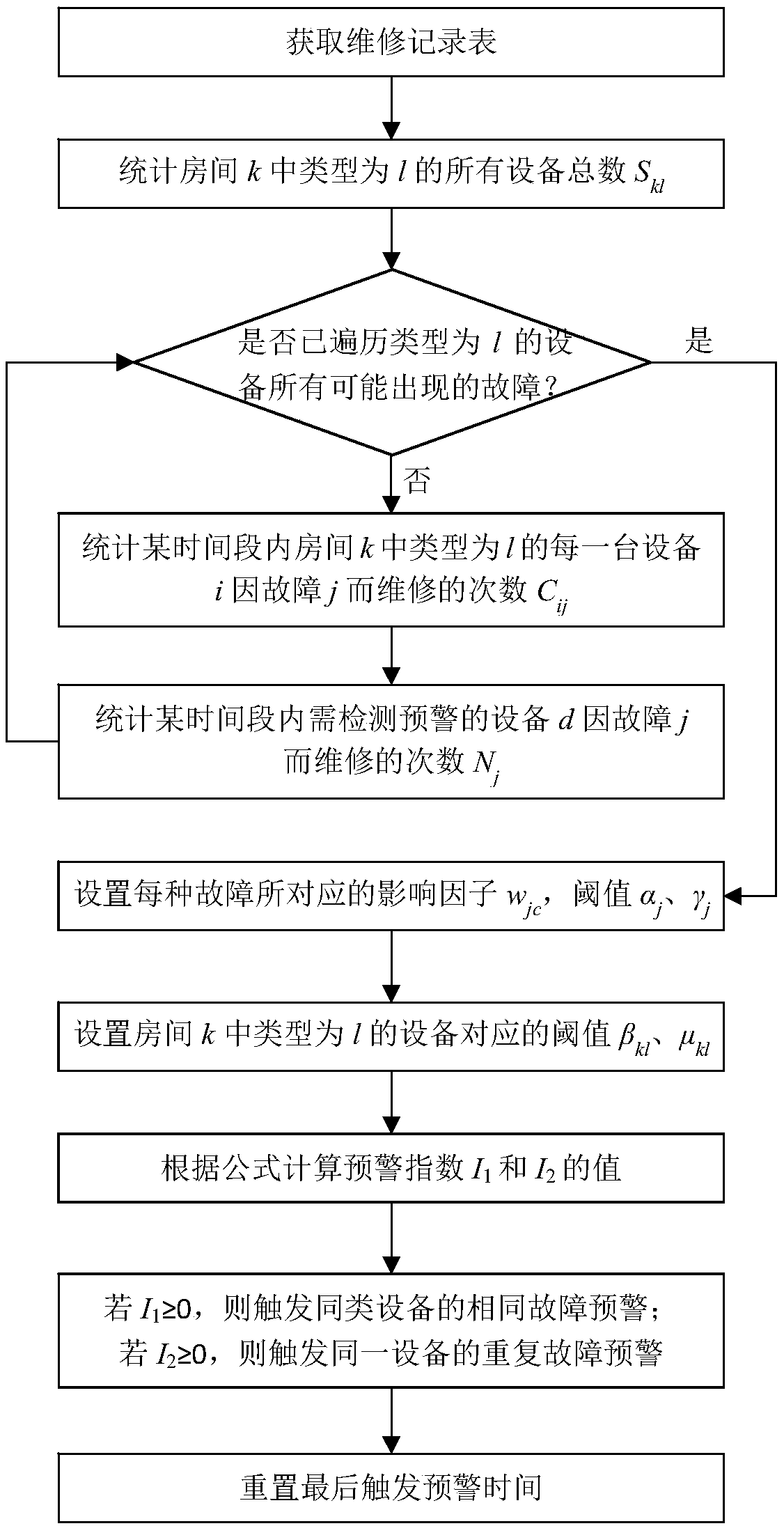

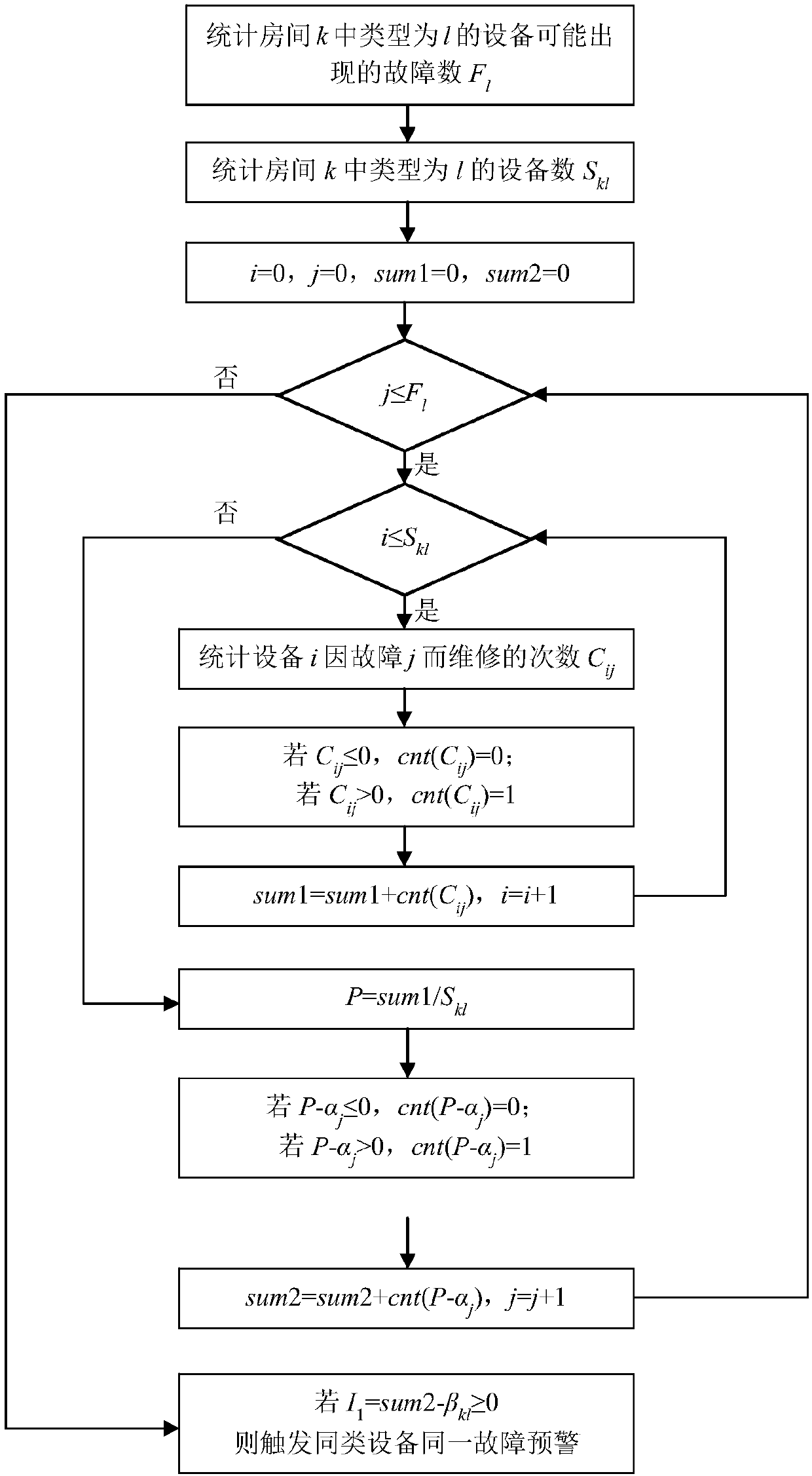

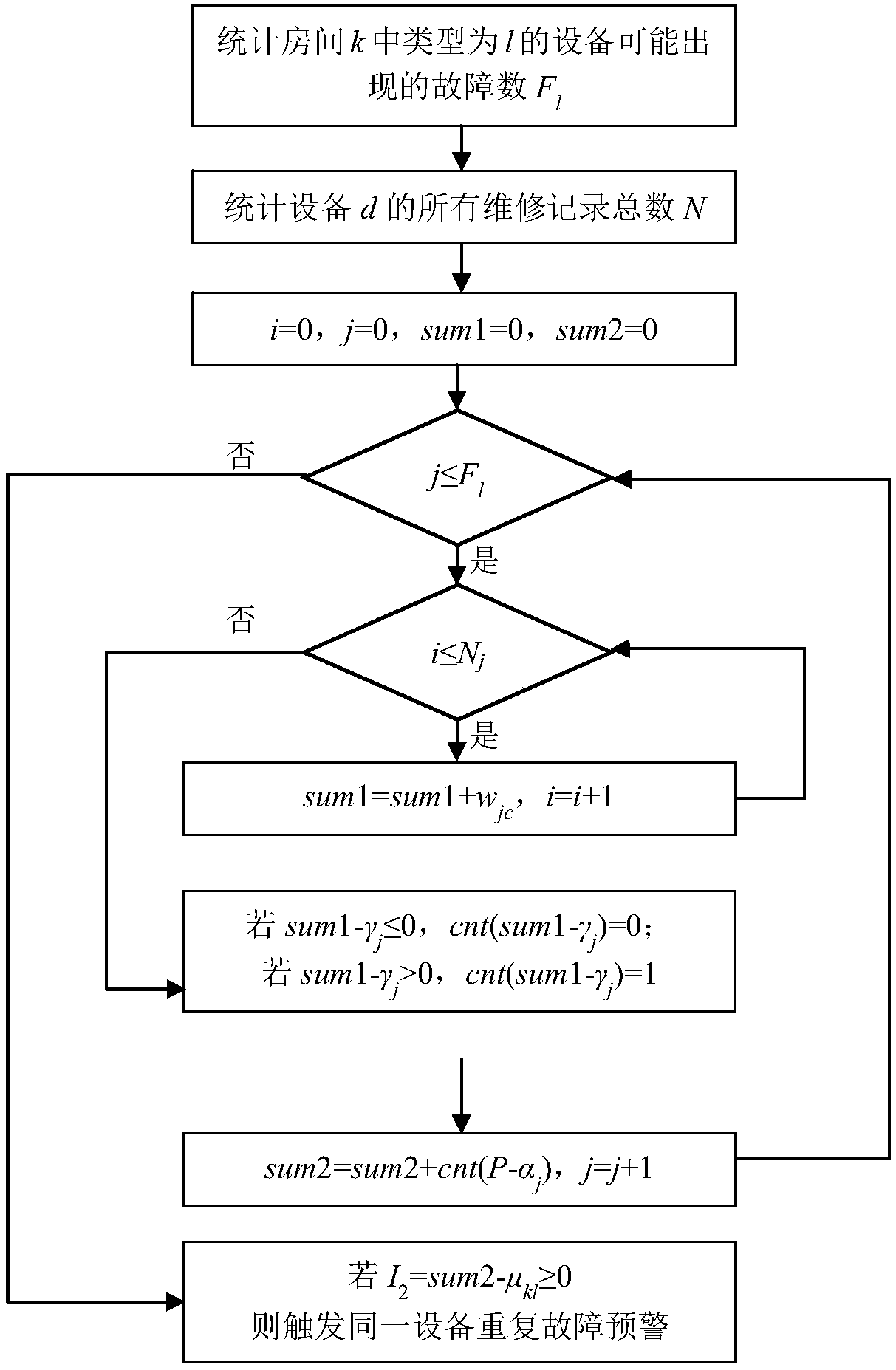

Method used

Image

Examples

Embodiment

[0057] A university has 1,000 computer equipment, and now the computer room k 1 l numbered 0001 in 1 Class equipment D performs fault warning. Specific steps:

[0058] 1) Obtain the maintenance record sheet, which includes the maintenance equipment number, room, equipment type, fault type, maintenance method and early warning time;

[0059] 2) Statistical computer room k 1 in type l 1 The total number of all equipment of 50;

[0060] 3) Statistical computer room k 1 Middle l 1 The total number of all possible failures of such equipment is 10; for each possible failure, repeat 4), 5);

[0061] 4) In the maintenance record table, machine room k 1 Middle l 1 The last time when this type of equipment triggered the same fault warning for similar equipment was at 12:00 on November 1, 2017. Taking this time as the starting point and the current time as the end point, the k 1 in each l 1 The number of times C that the equipment of type i is repaired due to failure j ij . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com