Method for judging whether gas well carries fluid normally or not

A gas well and normal technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inaccurate calculation of critical liquid-carrying flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a method for judging whether a gas well carries liquid normally. The critical liquid-carrying flow formula is deduced according to the droplet model, and the critical liquid-carrying flow rate of the gas well is calculated. Compared with the actual production of the gas-producing well, if the critical liquid-carrying flow rate is greater than If the actual production is lower than the actual production, the liquid carrying is abnormal, and the gas well will accumulate liquid. If the critical liquid carrying flow rate is less than the actual production, the gas well will carry liquid normally.

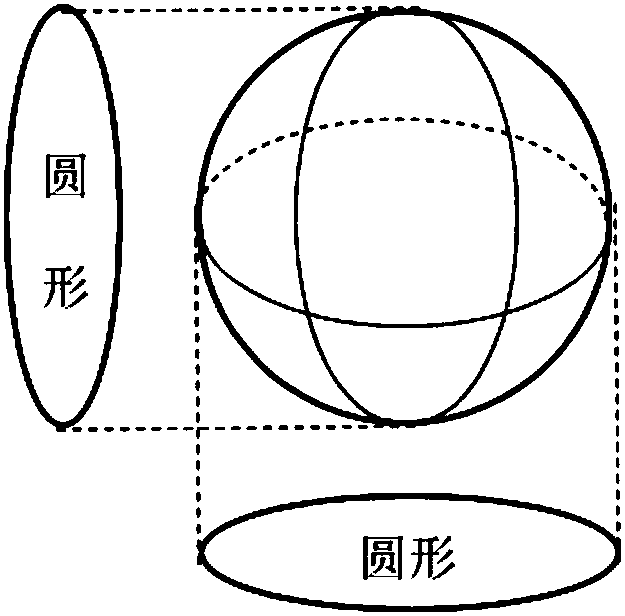

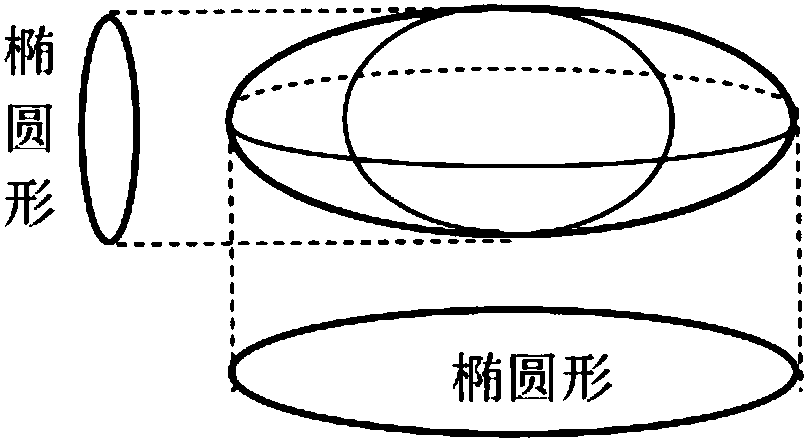

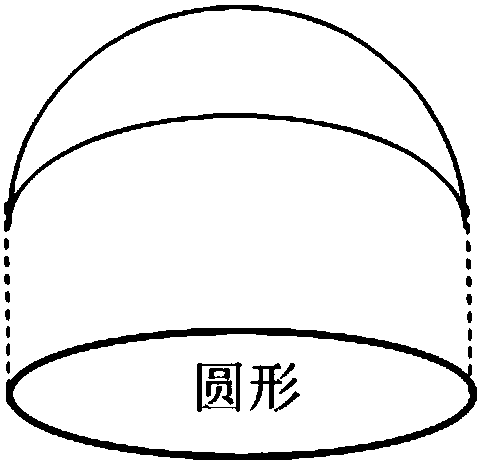

[0025] The invention calculates the minimum liquid-carrying flow rate of the gas well through the liquid droplet model, and judges whether the gas well accumulates liquid based on this. The invention proposes a new type of liquid-carrying droplet model for gas wells. The droplet model is an oblate spheroid. The projection of the model in the vertical direc...

Embodiment 2

[0027] On the basis of Example 1, this example provides a method for judging whether the gas well carries liquid normally, and deduces the critical flow velocity υ of the droplet according to the droplet model of the oblate spheroid and the force balance of the droplet in the critical state formula:

[0028]

[0029] The critical liquid-carrying flow formula is: Among them, g represents the acceleration of gravity, unit: m / s 2 ; d represents the inner diameter of the tubing, unit: m; p represents the wellhead oil pressure, unit: MPa; z represents the compressibility factor under the pressure and temperature of the tubing, dimensionless; T represents the temperature, unit: K; ρ l Indicates the density of the droplet, unit: Kg / m 3 ; ρ g Indicates the gas density, unit: Kg / m 3 ;σ represents the surface tension of natural gas and liquid droplets, unit: N / m; C D Indicates the drag coefficient, dimensionless.

[0030] Among them, the method of obtaining each parameter is a...

Embodiment 3

[0034] A well carried out a flow pressure test on March 19, 2016, and its test output was 1.2×10 4 m 3 / d, the oil pressure at the wellhead is 12.385MPa, and the temperature is 288.3K; the diameter of the tubing in this well is 62mm, the relative density of natural gas is 0.6, the compressibility factor z at this temperature and pressure is 0.753, and the density of the produced water in this block is 1009Kg / m 3 , Substituting the above data into the formula:

[0035]

[0036] The calculated critical liquid-carrying flow rate of the well is 2.2×10 4 m 3 / d, greater than gas well test production 1.2×10 4 m 3 / d, so the gas well is liquid-loaded; in the flow pressure test, there are two flow pressure gradients in the wellbore, 0.106MPa / 100m and 0.928MPa / 100m, and the liquid level depth of the gas well is 2198.28m. The theoretical settlement results are consistent with the actual test results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com