Control device and control method of press

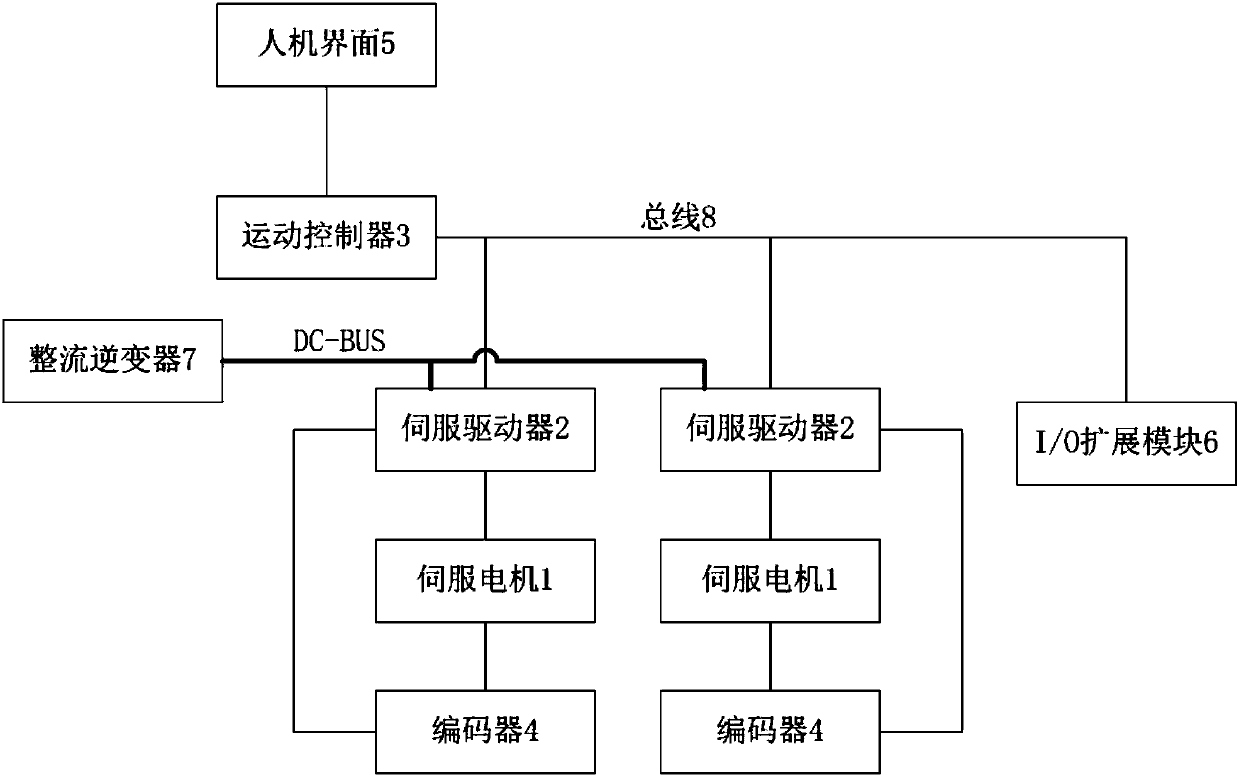

A control device and control method technology, applied in the field of press control, can solve the problems of unsatisfactory requirements, high delay of pressure sensor feedback signal, single motion track, etc., to achieve convenient monitoring and monitoring, low feedback signal delay, and anti-interference ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] An embodiment of the present invention provides a control method for a press, and the control method includes the following steps:

[0043] Step S1, the servo motor receives the control signal and runs;

[0044] Step S2, obtaining the driving current signal of the servo motor through the servo driver, and obtaining the torque value of the servo motor through the driving current signal;

[0045] Step S3, acquiring the position signal of the servo motor through an encoder;

[0046] Step S4, sending a closed-loop feedback control signal to the servo motor according to the torque value and the position signal, so as to modify the control signal and realize the closed-loop control of the servo motor.

[0047] The present invention obtains the position signal through the encoder 4 and feeds it back to the motion controller 3 to realize position closed-loop control. The drive current signal is obtained through the servo driver 2 and fed back to the motion controller 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com