Mechanism for rapidly measuring radial difference of outer wall of casing and its use method

A measuring machine and fast technology, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve problems affecting the guarantee of measurement accuracy, increase manufacturing costs, and increase manufacturing difficulty, so as to improve production efficiency and improve measurement The effect of high precision and convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with embodiment.

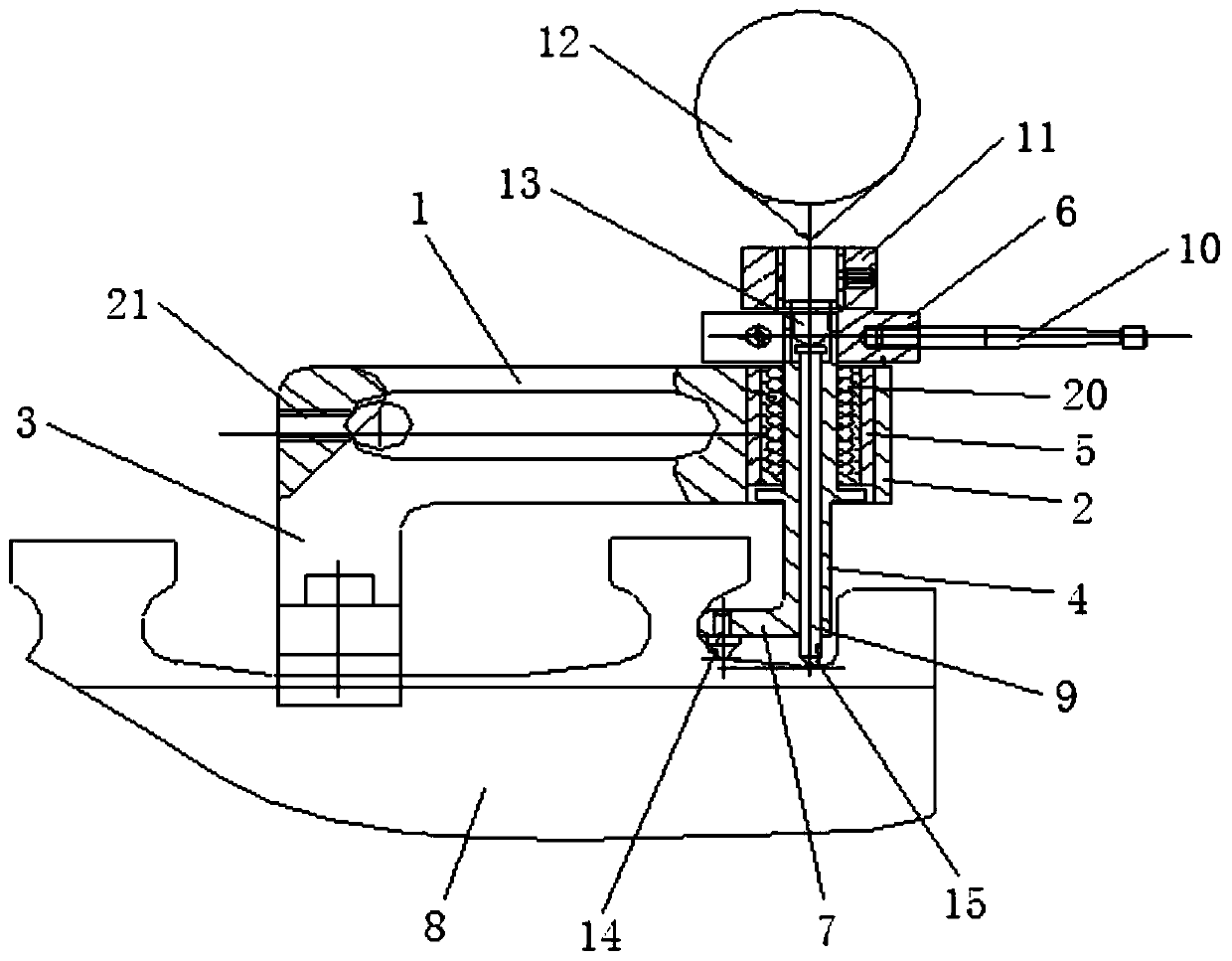

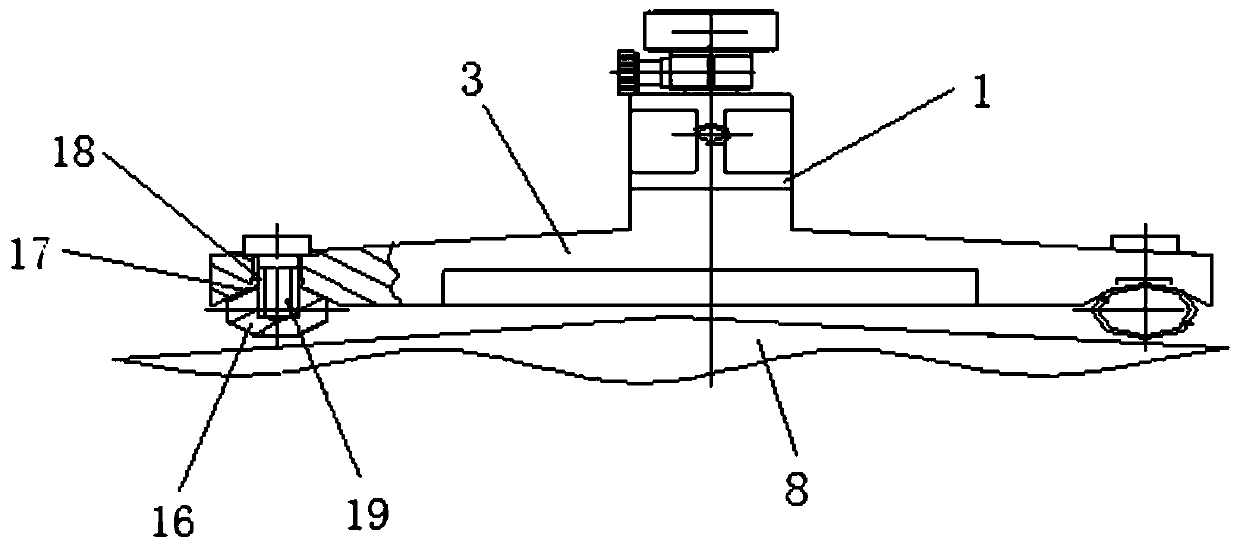

[0029] according to Figure 1 ~ Figure 2 As shown, the mechanism for quickly measuring the radial difference of the outer wall of the casing provided by the present invention is used to measure the radial difference of the outer wall of the casing. One end of the connecting beam 1 is provided with a measuring body 2, and its other end extends toward the outer wall of the casing 8 to form a positioning body 3. The positioning body 3 is a V-shaped structure, and the two V-shaped sides of the V-shaped structure are connected to the casing 8. The outer walls are in contact, and the measuring body 2 includes a fixed measuring rod 4 inserted in a through hole opened at the end of the connecting beam 1. A bushing 5 is installed in the through hole, and the bushing 5 surrounds the On the outer wall of the fixed measuring rod 4, and a linear bearing 20 is installed between the bush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com