Thickness measuring tool for disc component with complicated structure

A disc-like part with complex structure technology, applied in the field of thickness measuring tools, can solve problems such as difficulty, measurement interference, poor measurement accuracy, complex structure, etc., achieve strong versatility, improve measurement accuracy and pass rate, and avoid measurement interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

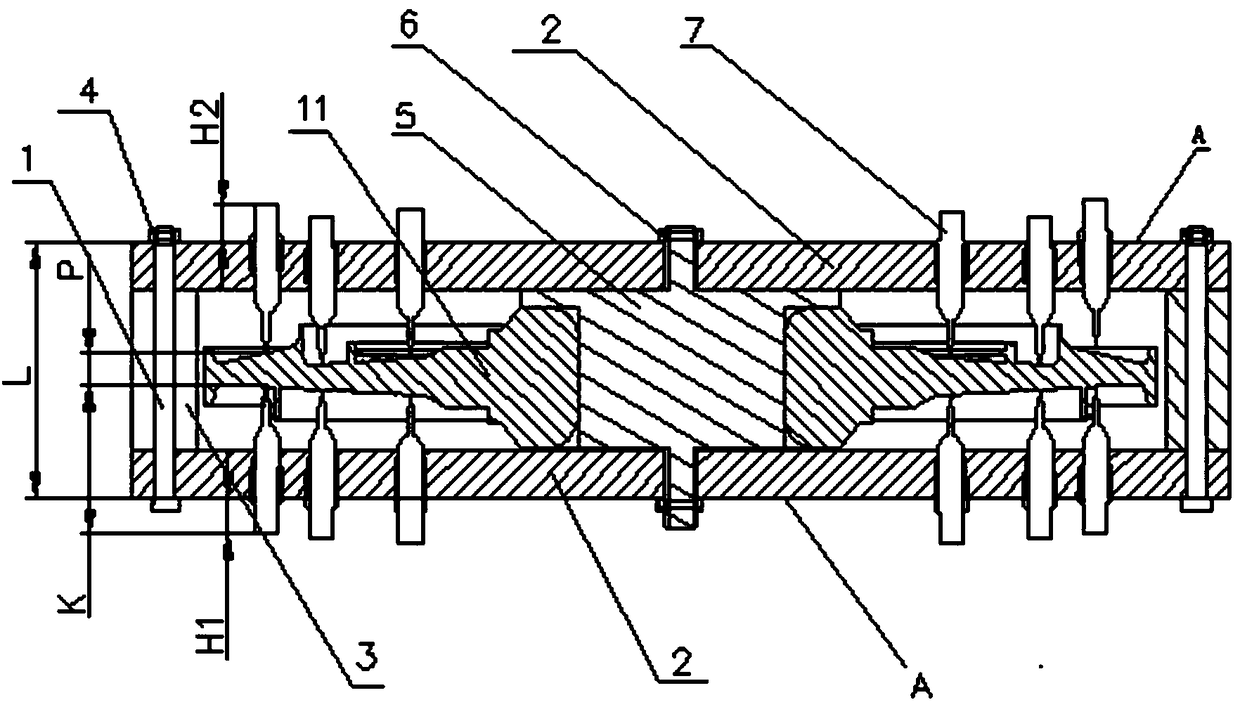

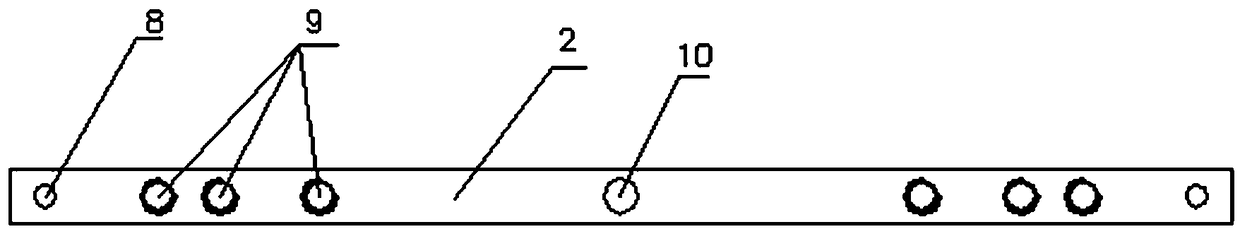

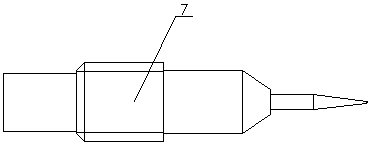

[0017] Such as Figure 1~3 As shown, a thickness measuring tool for disc parts with a complex structure includes a beam 2, a contour block 3, a positioning mandrel 5, a probe 7 and a fixing bolt 1. There are two beams 2, and two beams 2 Both ends are provided with fixing bolt holes 8, equal height blocks 3 are arranged between the two ends of the beam 2, fixing holes are arranged on the equal height blocks 3, fixing bolts 1 are arranged on the beam 2 to pass through the fixing bolt holes 8, and penetrate The fixing hole of the equal height block 3, the middle part of the beam 2 is provided with a mounting hole 10, and a positioning mandrel 5 is arranged between the two beams 2, and the positioning mandrel 5 is placed in the mounting hole 10, and the beam 2 is also provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com