A device for detecting the symmetry of the tenon and groove of a turbine disk

A detection device and turbine disk technology, applied in the direction of angle/taper measurement, etc., can solve the problems of low efficiency, long detection time, inconvenient operation, etc., and achieve the effect of high accuracy, simple operation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

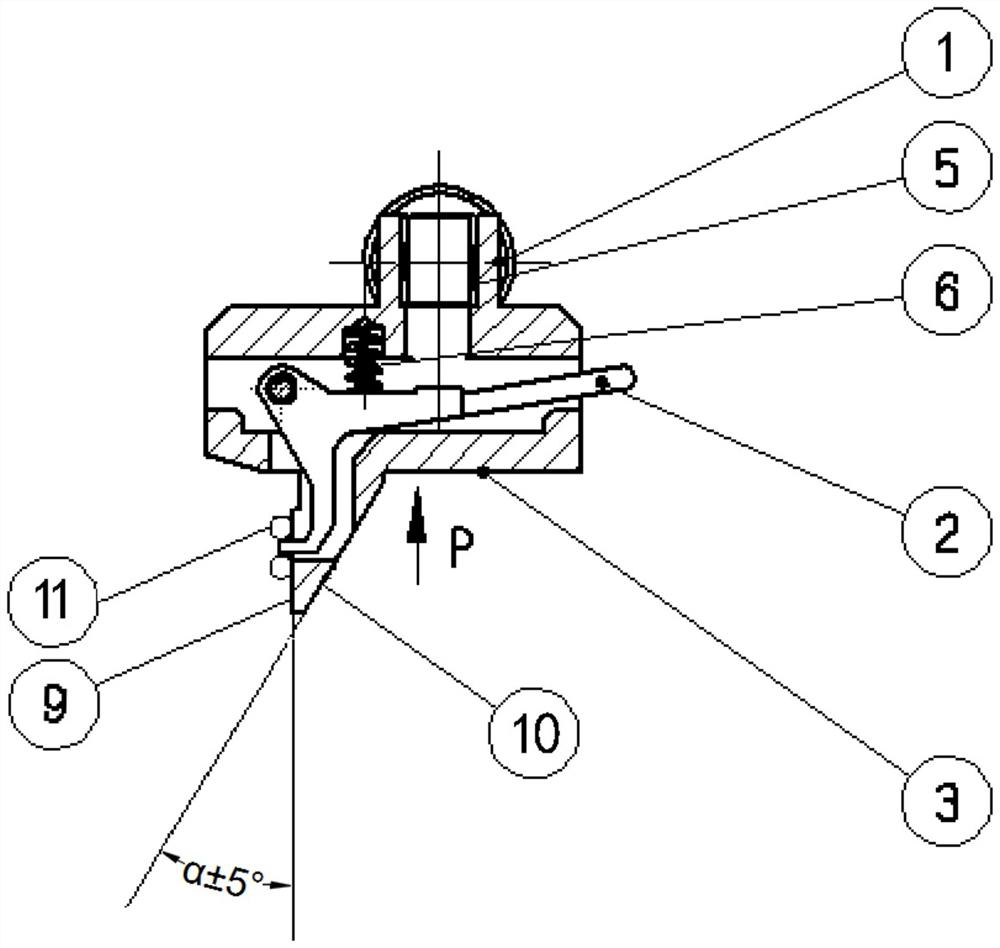

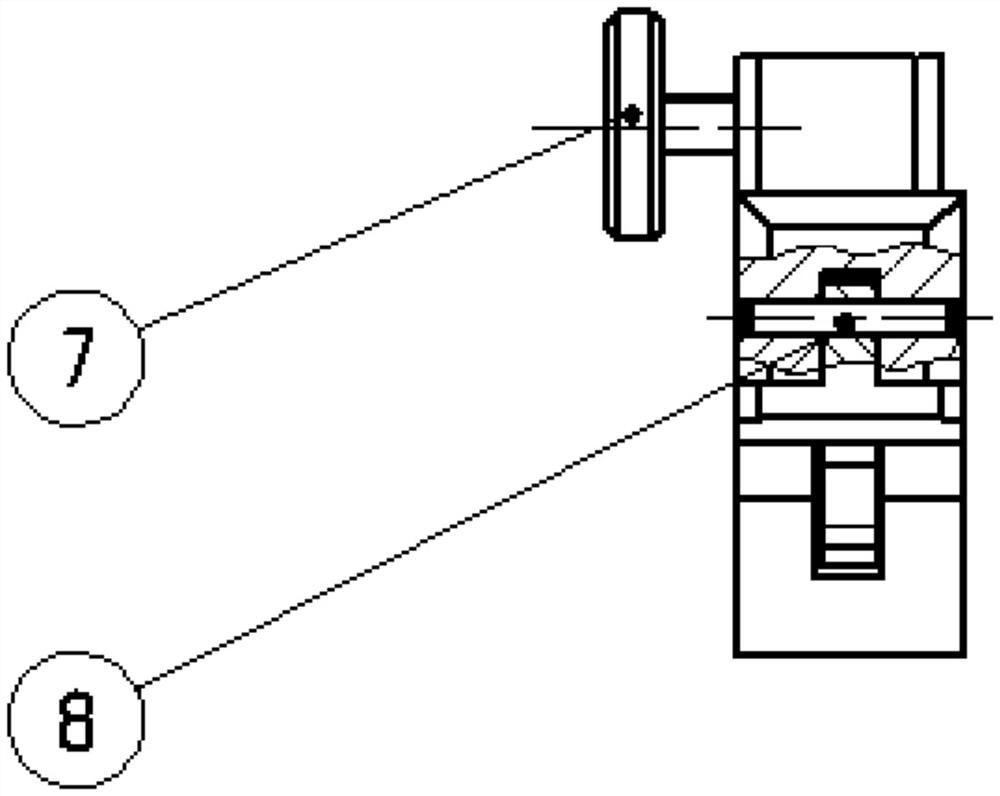

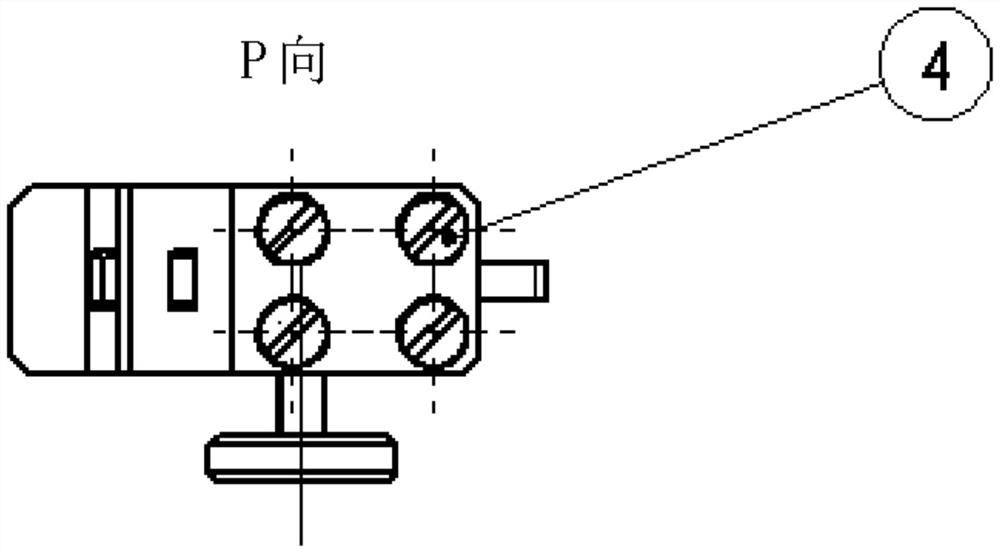

[0017] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

[0018] Such as Figure 1-3 As shown, a turbine disk tenon and groove symmetry detection device includes a table base 1, a positioning block 3, and a lever 2. The positioning block 3 is fixed on the bottom of the table base 1 by slotted cylindrical head screws 4, and a shaft is fixed on the table base 1. The pin 8, the lever 2 and the shaft pin 8 are in clearance fit, and the gap is maintained at 0.005-0.01 mm, and the two sides of the lever 2 and the table seat 1 are kept at a gap of 0.005-0.01 mm. The lever 2 has a 90° rotation angle to realize the transmission of the measured value; positioning Block 3 has mutually perpendicular grooves, and the two ends of lever 2 rotate around pivot pin 8 in two grooves of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com